Aluminium Alloy Plate for Boat 5052 5083

Aluminium Alloy Plate for Boat 5052 5083: The Unsung Hero of Marine Crafting

When thinking about building or upgrading a boat, most conversations orbit around design, engine power, or onboard amenities. However, the real foundation of marine durability lies in the material beneath the surfaces—the aluminium alloy plate, particularly types 5052 and 5083. These alloys aren’t just raw metals; they are engineered marvels that marry strength, corrosion resistance, and lightweight efficiency, ensuring that watercraft not only perform but endure.

Why Aluminium Alloy Plates Matter in Boat Construction

Much in the way a chef chooses specific ingredients for their dish, boat builders select alloy plates that can withstand harsh marine environments while balancing weight and strength. Aluminium alloy plates, such as grades 5052 and 5083, are favored because they expertly resist seawater corrosion without the heavy maintenance that steel demands.

Working with 5052 and 5083 aluminum alloy plates for boat building presents a unique set of challenges and rewards. 5052, with its higher manganese content, offers excellent corrosion resistance, particularly in marine environments. This is crucial for longevity, minimizing maintenance, and ensuring structural integrity. However, its slightly lower strength compared to 5083 means careful consideration must be given to plate thickness and design, especially in high-stress areas like hull bottoms and keels. We've seen instances where insufficient thickness in 5052 led to premature fatigue cracking, highlighting the need for precise calculations and adherence to industry best practices. Weldability is also a factor; proper welding techniques are paramount to avoid porosity and maintain the alloy's corrosion resistance.

The higher strength of 5083 makes it a popular choice for applications requiring greater structural rigidity, such as larger boats or those subjected to significant impact. However, its slightly lower corrosion resistance compared to 5052 necessitates meticulous surface preparation and potentially the use of protective coatings to prevent pitting and galvanic corrosion, especially when in contact with other metals. We've found that pre-treatment with a suitable primer and a high-quality marine-grade paint system is vital for long-term performance. Furthermore, the selection of the correct welding process and filler material is crucial to avoid compromising the strength and corrosion resistance of the weld joint. these nuances

Diving Deeper: What Makes 5052 and 5083 Stand Out?

Aluminium 5052 Alloy Plate

5052 is the steadfast workhorse—an alloy primarily composed of aluminum, magnesium (about 2.5%), and chromium. Its strong resistance to saltwater, combined with excellent formability, aligns perfectly with boat hulls that require shaping and detailing. Its tensile strength ranges typically from 193 to 275 MPa, making it flexible enough for intricate parts yet solid against wear.

- Why choose 5052?When building smaller vessels or superstructures on larger ships, 5052’s moderate hardness and ability to absorb impact without cracking make it the go-to. Its weldability spares the builder complications on site, accelerating assembly without losing quality in strength or finish.

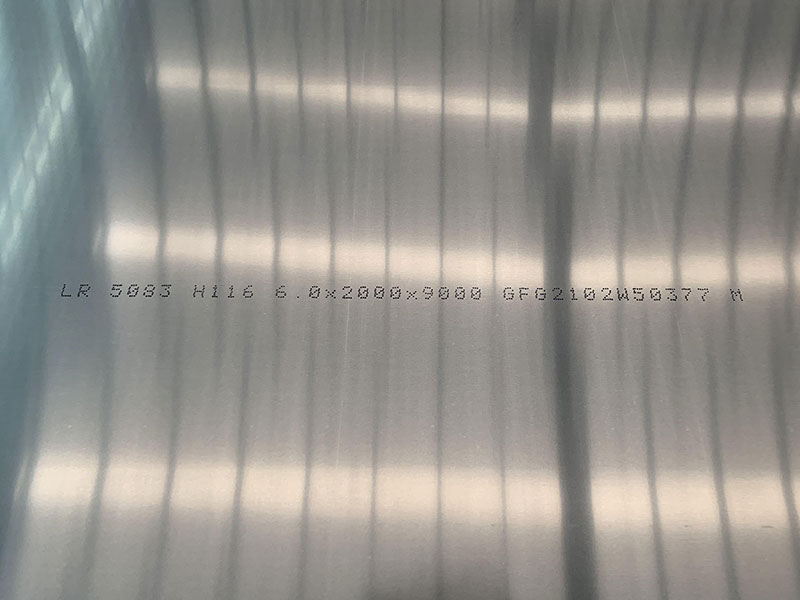

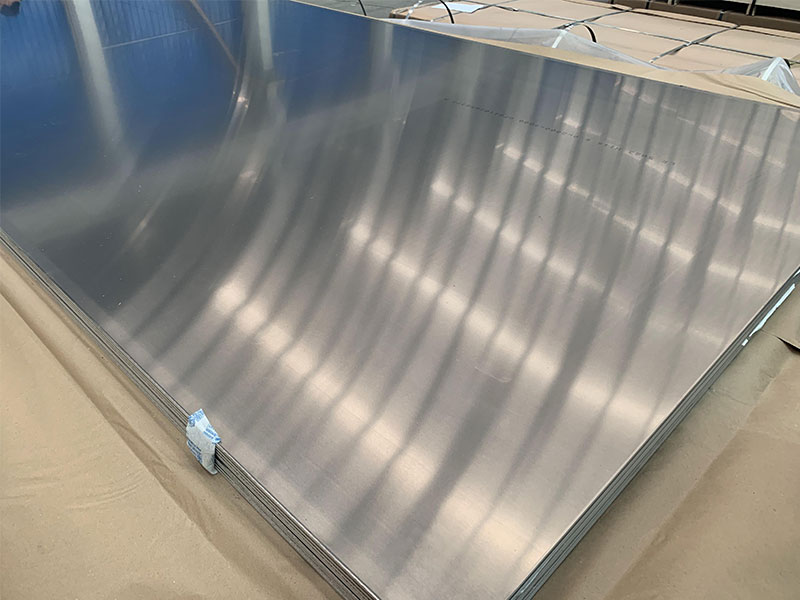

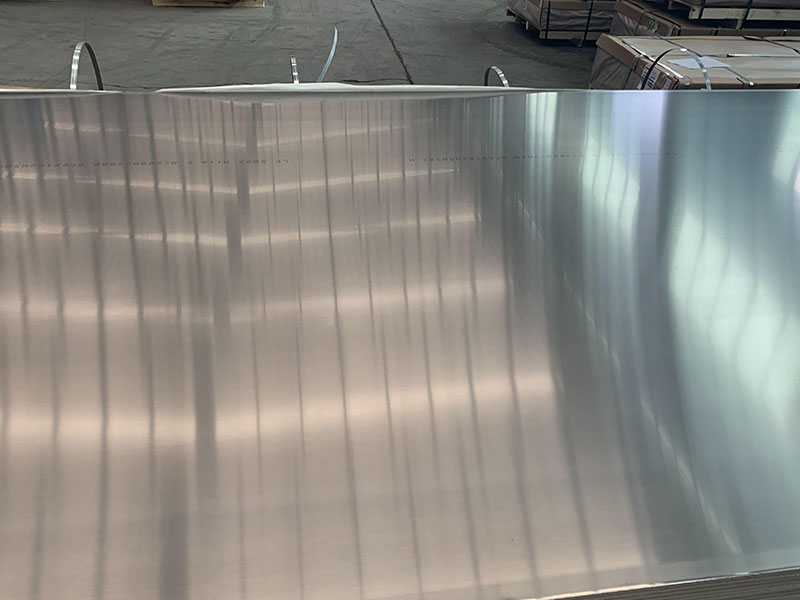

Aluminium 5083 Alloy Plate

5083 steps into competition as the heavyweight champion of marine-grade aluminium. Enriched with magnesium (about 4.0%-4.9%) and traces of manganese and chromium, it delivers superior tensile strength—around 317 MPa—and seemingly unrivaled corrosion resistance, especially against seawater and industrial solvents.

- The 5083 advantage:Ideal for thick hull plates and structural components, this alloy withstands extreme conditions, including salt spray, extreme humidity, and even cryogenic temperatures. Its high strength-to-weight ratio balances ship safety while not tipping off buoyancy calculations.

From Material to Masterpiece: Practical Insights for Builders and Buyers

Choosing between 5052 and 5083 shouldn’t just reflect availability or cost—it hinges on the intended application. A recreational boat, cruising calm waters, benefits from the flexibility of 5052. Meanwhile, commercial fishing vessels, patrol boats, or heavy-duty crafts anchoring in storm-prone areas rely heavily on 5083’s robust endurance.

Maintenance Tips:Although both alloys reduce rusting concerns, daily patrols for scratches or dents extend life dramatically. A protective coating or anodizing amplifies corrosion safeguards further.

Sustainability and Lifecycle:Aluminium alloy plates are highly recyclable, underpinning sustainable shipbuilding practices. With increasing regulation on marine emissions and waste, their reuse benefits ecology without compromising future function.

https://www.aluminumplate.net/a/aluminium-alloy-plate-for-boat-5052-5083.html