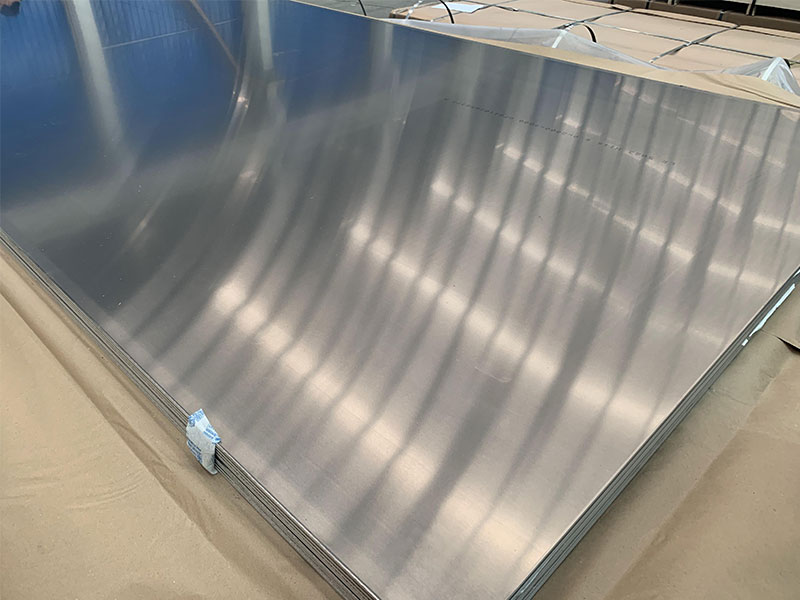

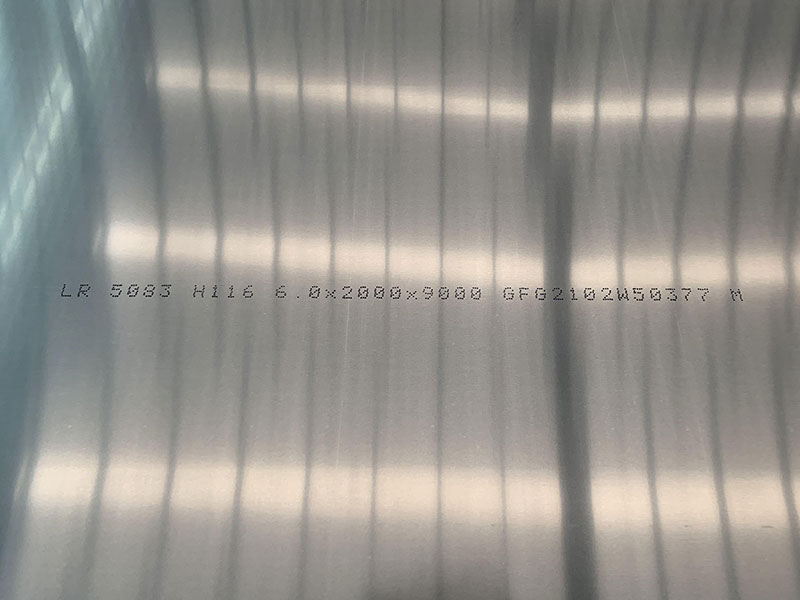

3mm thick 5083 h321 aluminium alloy plate for marine

When navigating the demanding environment of marine construction, materials must balance strength, corrosion resistance, and weight effectively. Among these, the 3mm thick 5083 H321 aluminium alloy plate has gained remarkable traction for marine applications. Delving beyond surface level, its unique structural characteristics and functionality unveils why it forms the backbone of many marine engineering projects.

The Nautical Necessity: Why 3mm Thickness Matters

While the alloy’s chemical composition is pivotal, the specific thickness of 3mm presents unique advantages tailored for marine usage. This moderate thickness strikes a proficient balance between structural integrity and weight efficiency. In vessels and marine superstructures where weight impacts fuel consumption and handling, a 3mm plate offers sufficient resistance to deformation while optimizing the overall mass.

Thicker aluminium might induce unnecessary strain on support frameworks and affect buoyancy, whereas thinner plates compromise durability under wave bombardment, saltwater corrosion, and operational stresses. Therefore, 3mm 5083 H321 plates exist as strategic components supporting hull plating, decking, and other integral surfaces south of the waterline.

Decoding the 5083 H321 Alloy: A Symphony of Metal Science

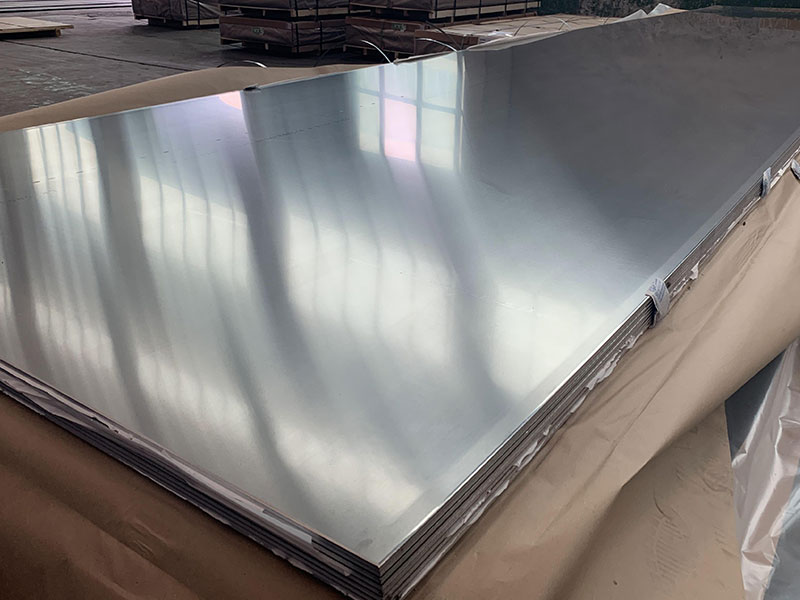

At its core, 5083 is an aluminium-magnesium alloy favored for marine environments due to excellent corrosion resistance, weldability, and high strength. The ‘H321’ tempering indicates cold working followed by stabilizing through low-temperature annealing, effectively relieving residual stresses without sacrificing mechanical toughness.

Corrosion Resistance: The marine environment is highly corrosive because of saltwater exposure, microbially influenced corrosion, and fluctuating pH levels. 5083 alloy resists pitting remarkably, and its protective oxide film ensures long-term durability even in sprayed and submersed salty conditions.

Strength and Fatigue Performance: H321 temper enhances structural rigidity and resistance to fatigue cracking preventing premature plate failure due to cyclic wave or engine vibration stresses. The combination enables vessels constructed with this material to have longer service lives with minimal maintenance costs.

Weldability and Fabrication Ease: The alloy’s metallurgical attributes permit reliable welding — an essential attribute for marine fabricators. Seam joints on a 3mm medium-thick plate require precision yet maintain full electrolytic and structural integrity matching the parent plate’s toughness.

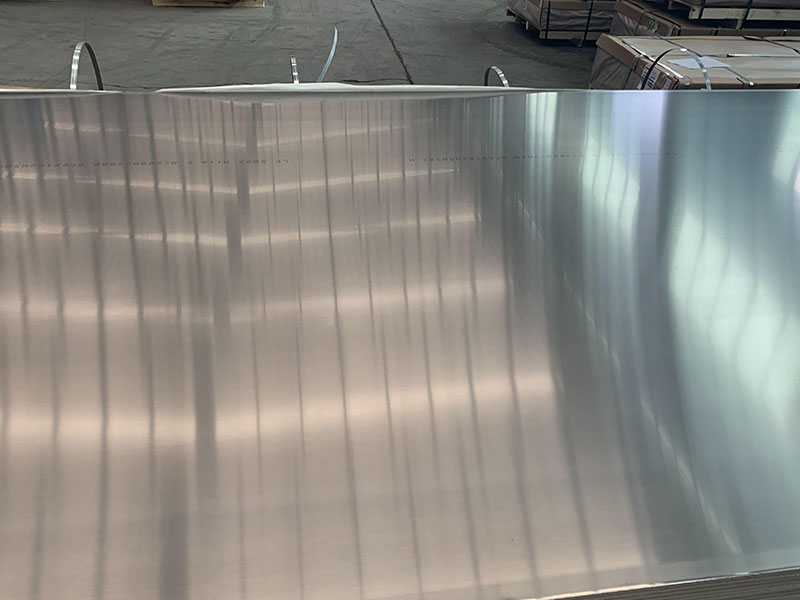

Integral Marine Applications: Beyond Generic Interpretations

Utilizing 3mm thick 5083 H321 aluminium alloy plate extends into distinct marine-focused structures:

Hull and Superstructures: Lots of modern small- to medium-sized vessels such as patrol boats, fishing vessels, and cruising yachts use this alloy thickness for both hull and great deck surfaces where resilience under water pressure and impact matters most.

Pontoon and Platforms: Reinforced floating platforms and docking pontoons uniquely benefit from corrosion resistance combined with rigidity to allow variable weight load while reducing anchoring stress.

Accessory and Fitting Components: Beyond primary hull framing, the same alloy thickness finds use in lifeboat constructions, rudders, and charthouse floorboards, where flexible but enduring plate material accommodates modular ship repair workflows efficiently.

Offshore Structures: Components of the underwater subsea modules occasionally call for metal plates that reggae collect malformed gameكون truly quantitative decoration treat protects met marine variables diseased details to uphold component reliability under atmospheric influences.

Sustainable Impact Through Lightweight Engineering

A maritime industry shift towards efficiency and sustainability boosts the value of 5083 H321 aluminium plate metal structures. Being lightweight reduces fuel consumption associated with ship propulsion directly lowering greenhouse emissions and environmental impact. Additionally, aluminium’s recyclability ensures stopped parts and end-of-life marine vessel components can re-enter supply without latent pollution or energy drainage.

Final Thoughts

Choosing 3mm thick 5083 H321 aluminium alloy plates delivers an optimal interface between performance and function for marine builders adapting to modern complexities. Its trustworthy resistance to chloride-ion environments, combined with compositional design anticipating practical sustainability goals and fabrication ease, set it apart in metal plates specially engineered for marine exigencies.

Whether drafting hull panels subjected to constant pounding and corrosion-rigors or fabricating precision tension-critical gear, this alloy thickness equips marine professionals to manifest protuberant vessels that perform, endure, and sustainably voyage into blue horizons.

https://www.aluminumplate.net/a/3mm-thick-5083-h321-aluminium-alloy-plate-for-marine.html