0.4mm aluminum mirror sheet

In the realm of advanced materials, the 0.4mm aluminum mirror sheet emerges as a remarkable solution that elegantly marries aesthetics with function. While thicker mirror sheets command attention for their rigidity, the thinner 0.4mm aluminum mirror sheet stands out for its unique blend of lightweight endurance and pristine reflectivity, making it indispensable across various cutting-edge industries.

What is a 0.4mm Aluminum Mirror Sheet?

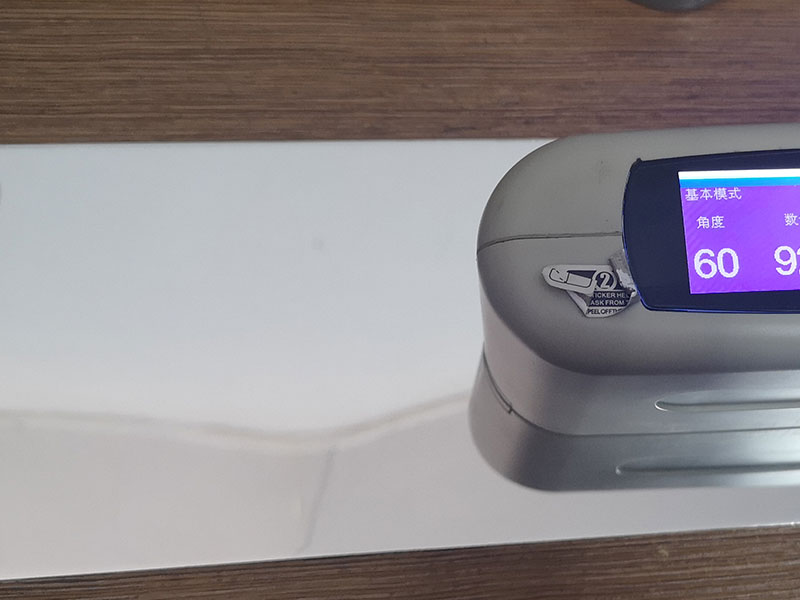

At just 0.4mm thick, this ultra-thin reflective aluminum panel is precision-engineered to boast exceptional surface smoothness and reflectivity, mimicking a conventional mirror yet significantly lighter and more adaptable. Constructed from high-purity aluminum, these sheets undergo a rigorous polishing process that yields a distortion-free mirrored surface, capable of reflecting up to 88-92% of visible light—surpassing many traditional mirror substrates made from glass.

Technical Attributes

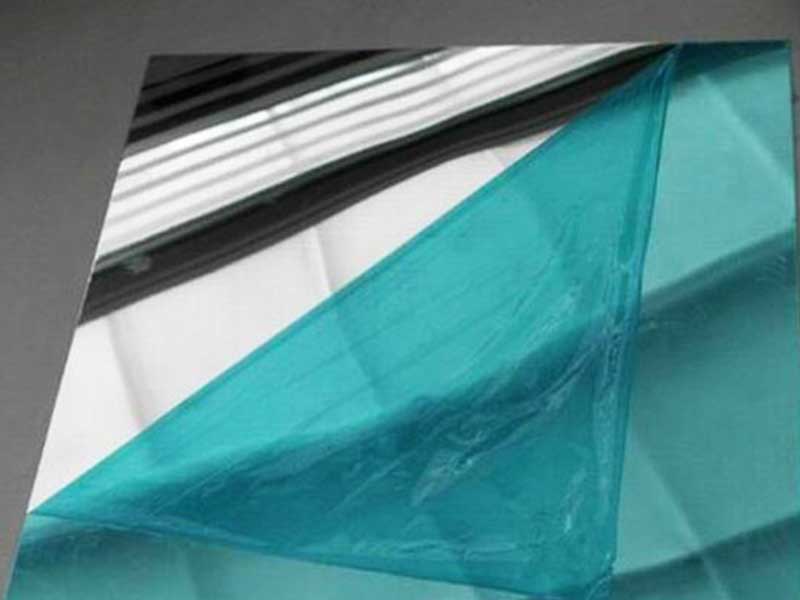

- Thickness & Flexibility: The 0.4mm gauge balances optimal thinness with durable performance, allowing flexibility without cracking—a major advantage where curved or complex surface application is desired.

- High Reflectivity: Through advanced electro-polishing techniques, the aluminum mirror sheet achieves a nano-level polished finish resulting in high-reflectance efficiency in the visible spectrum.

- Corrosion Resistance: Though aluminum naturally forms a self-protecting oxide layer, these mirror sheets are often anodized or coated to enhance durability and resist environmental degradation.

- Weight Advantage: Weighing approximately one-third that of glass mirrors, 0.4mm aluminum sheets reduce load significantly with no compromise on reflective quality.

- Impact Resistance: Unlike brittle glass mirrors, these aluminum sheets resist shattering—ideal for safety-concerned environments.

Functional Benefits of 0.4mm Aluminum Mirror Sheets

Beyond aesthetics, the functional versatility of these sheets is profound. Their enhanced reflectivity plays a critical role in optimizing light distribution, while the mutable thinness supports imaginative designs constrained by weight or geometries—applications where traditional glass mirrors may fail.

- Precision Light Redirection: In optical instruments and lighting fixtures, the 0.4mm aluminum mirror sheet provides consistent, high-quality reflections with minimal distortion.

- Thermal Management: Reflective properties aid in heat control applications, where infrared light reflection helps reduce thermal build-up.

- Sound Reflection: Their smooth surface doubling as hard-surfaced panels can enhance acoustic enclosure designs.

- Customizable Engineering: Easily cut or bent without fracturing, enabling seamless integration in present-day technological and architectural innovations.

Applications Across Industries

The distinct micro-thickness combined with the robustness of aluminum opens extensive application opportunities:

- Architectural Decor & Interior Design: Line walls, ceilings, or furniture details with 0.4mm aluminum mirror sheets for a modern metallic aesthetic, lightweight enough to mount without excessive structural support.

- Automotive Components: Reflective interiors for lighting reflectors, trim accents, and dashboard facades—earning praise for excellent durability and lightweight resilience.

- Electronics & Consumer Devices: From reflective backplanes in display technology to smartphone casings polished for volume aesthetic, these composite mirrors improve visual effects without the bulk.

- Solar and Renewable Energy: As reflective concentrators in solar thermal plants, these sheets augment sunlight redirection into highly focused beams maximizing energy capture effectiveness.

- Advertising & Graphic Display: Used as reflective substrates in signage, creating eye-popping mirrored advertising displays which attract attention by bouncing vibrant light around exhibition spaces.

- Marine Industry: Corrosion resistance and impact-resistance make these panels suited to boat interiors where standard glass won't endure humidity.

Why Choose 0.4mm Aluminum Mirror Sheets?

Not only does the unique 0.4mm thickness confer weight and flexibility advantages, but its intrinsic properties fulfill the growing need for safe, sustainable mirror solutions in engineering lean environments. When compared to heavier glass mirrors or plastified counterparts, the aluminum mirror marries durability with easy handling and versatility of finish options—from plain highly polished to color anodized finishes.

In Conclusion

The 0.4mm aluminum mirror sheet represents a sophisticated material choice bridging between technical requirements and visual excellence. Its extraordinary reflective abilities paired with lightweight resilience facilitate long-lasting innovation—from high-tech manufacturing to elegant architectural designs. As demand swells for materials that perform without compromise, the magic lies in trusting this ultra-thin aluminum marvel to reflect your vision flawlessly—both literally and figuratively.

If you seek a premium, versatile reflective surface that balances aesthetics, performance, and weight, the 0.4mm aluminum mirror sheet is undoubtedly an essential material to add to your design and manufacturing toolbox.

https://www.aluminumplate.net/a/04mm-aluminum-mirror-sheet.html