5052 503 5082 5086 Aluminum Sheet

5052 503 5082 5086 Aluminum Sheet: A Friendly Guide to These Mighty Metals

When it comes to aluminum sheets, those numbers like 5052, 503, 5082, and 5086 might sound like secret codes. But behind these codes lie some of the most reliable and versatile metals you’ll find in everyday life.

The Nuts and Bolts of These Aluminum Sheep

First off, these four (5052, 503, 5082, and 5086) belong to what we call the 5xxx series aluminum. That’s jargon for “alloyed mostly with magnesium.” What does that mean for you? Magnesium brings good stuff to the party: higher strength than plain aluminum, excellent corrosion resistance (especially against saltwater), and great workability. People often praise this series because it balances strength with being light as a feather.

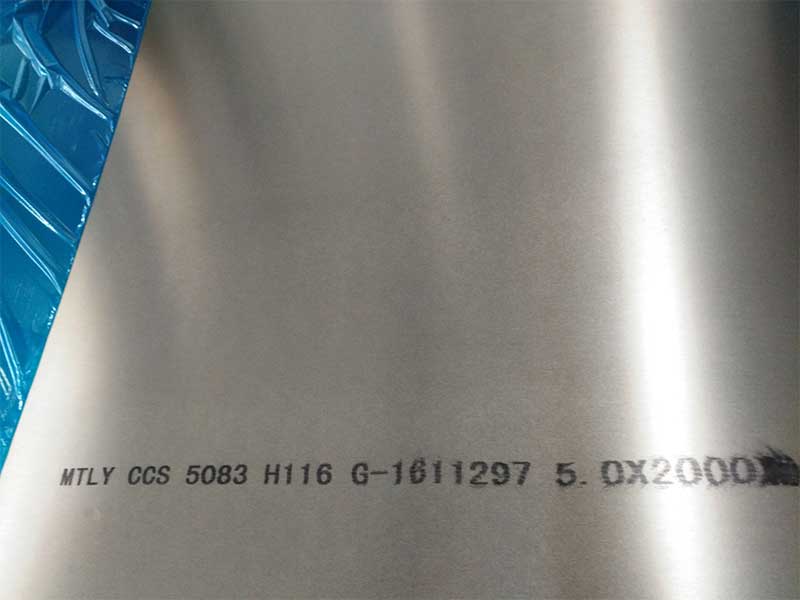

Working with 5052, 503, 5082, and 5086 aluminum sheets daily reveals distinct characteristics that impact their application. 5052, with its high magnesium content, excels in marine environments due to its superior corrosion resistance. We often see it used in boat hulls and other components exposed to saltwater. However, its lower strength compared to 5086 necessitates careful consideration during design. Conversely, 5086, a high-strength, weldable alloy, is favored for structural applications where durability is paramount. It's a common choice in transportation manufacturing, especially where welding is involved. 503, while less common in our factory, often finds its niche in applications demanding good formability and corrosion resistance, but not necessarily high strength. The subtle differences in these alloys – even between 5082 and 5086 which are both strong – highlight the need for precise material selection based on the intended end-use.

the nuances of these alloys is critical for efficient production. For instance, 5086's higher strength requires adjustments in our forming processes to prevent cracking or tearing, whereas the superior weldability of 5086 allows for faster production cycles compared to some other alloys. We've also found that the differing responses to various surface treatments necessitate tailored approaches. these intricacies allows us to optimize our processes,

Breaking it down:

5052 Aluminum Sheet: The all-star. It's got a nice mix of strength, resistance to corrosion, and flexibility. Being one of the more popular choices, it’s great for marine environments, fuel tanks, and pretty much any project where strength and rust-resistance matter.

503 Aluminum Sheet: Think of 503 as a close cousin to 5052, but it isn’t standardized in some regions. It occasionally pops up in specialized uses but is less common. It shares the 5xxx promise of durability, though specifics on it are more niche.

5082 Aluminum Sheet: Bulk up! When you want something stronger and able to handle more pressure or force, 5082 takes the spotlight. It still loves saltwater and carries heavy workloads, making it fantastic for shipbuilding and pressure vessels.

5086 Aluminum Sheet: Meet the heavyweight contender in this quartet. 5086 offers even higher tensile strength and top-tier corrosion resistance, especially against marine environments. Light boats, military vehicles, or structural parts that demand resilience often rely on this star performer.

Why Does Technical Stuff Matter? Because It Translates to Real Life

The unique alloy composition influences things that matter in actual use:

Corrosion Resistance: Because magnesium helps fight rust, these sheets often survive where others crumble. Notice this in boats sprayed by saltwater or outdoor structures getting hammered by rain.

Strength and Formability Balancing Act: If a sheet’s too hard, turning it into complex shapes is a nightmare. Here, these alloys shine since they’re easy enough to bend or weld, but strong enough to keep their shape during your toughest projects.

Weldability: Though not stainless steel, 5xxx series aluminum doesn’t throw tantrums when welded, allowing manufacturing ease for everything from tanks to automobile parts.

Real-World Walkthrough: See The Sheets in Action

Marine Applications: It’s no surprise that 5052, 5082, and 5086 aluminum sheets hold sailor-approved safe spots on boats, ship hulls, and floating docks. Their corrosion resistance protects crafts prized by fishers and leisure seekers alike.

Automotive Industry: From truck fuel tanks to body panels, these sheets reduce weight (good for fuel economy) while ensuring safety and durability, making modern cars lighter and stronger.

Architecture and Construction: When you want clean-looking claddings that smile against elements for years, employing alloys like 5052 or 5082 in roofing panels or facades can be quite standard.

Industrial Equipment: Pressure vessels, gas tanks, and heavy machinery components also rely on these alloys because they withstand pressure extremes without failure.

Wrapping It Up

Talking about 5052, 503, 5082, and 5086 aluminum sheets isn’t just about science jargon or catalog listings. It’s about picking the right buddy for your project who stands strong, resists corrosion, and keeps things light on your hand and wallet. Whether it’s sailing through salty waves or staying tough on your worksite, these alloys deliver performance with few compromises.

—

https://www.aluminumplate.net/a/5052-503-5082-5086-aluminum-sheet.html