Mill Finish Aluminum Sheet 1060 1050 1100 3003 5005 5052

The Untold Versatility of Mill Finish Aluminum Sheets: A Dive into Alloys 1060, 1050, 1100, 3003, 5005, and 5052

When envisioning traditional materials for construction, manufacturing, or artistic endeavors, aluminum should effortlessly enter that conversation. One of its most favored forms, the mill finish aluminum sheet, serves various industries with elegance and practicality. However, not all aluminum sheets are created equal. Distinguishing between various alloys like 1060, 1050, 1100, 3003, 5005, and 5052 unveils a unique tapestry of capabilities that each alloy offers.

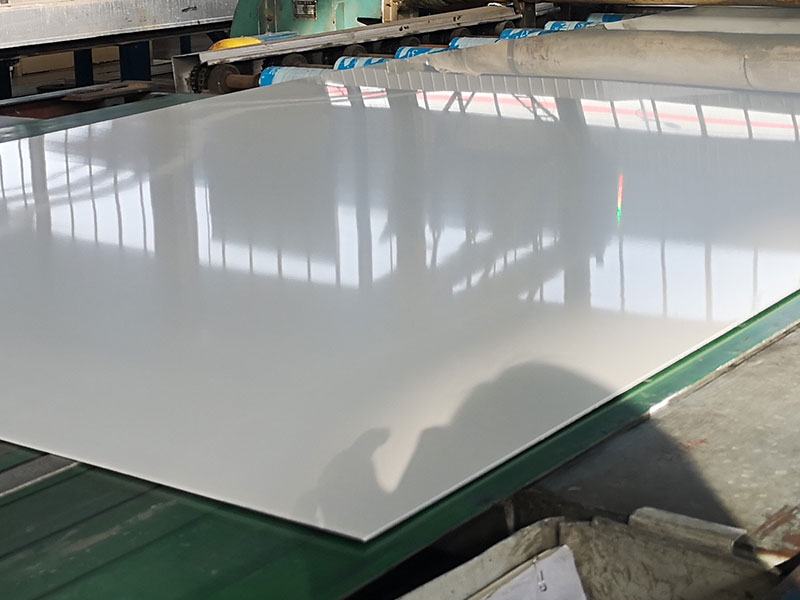

Mill Finish Aluminum Sheets

Mill finish aluminum sheets denote a surface treatment following processes like rolling or extruding without additional coating. This finish has benefits such as reflective properties and high resistance to oxidation. Furthermore, these sheets can be lightweight yet incredibly durable, making them suitable for multiple aerospace, automotive, architectural, and decorative uses.

Aluminum Alloy Breakdown

Alloy 1060:In the pantheon of pure aluminum, alloy 1060 reigns supreme. With a minimum aluminum content of 99.60%, it boasts a significant advantage in corrosion resistance. The reduced price per pound renders it a popular choice for sectors requiring non-ferrous compositions—think electrical bus bars and heat exchangers. Its excellent workability shines when fabricated into intricate shapes, making alloy 1060 a staple in electrical applications and chemical storage.

Alloy 1050:Slightly different yet sharing its purity, 1050 aluminum alloy is used in applications demanding excellent corrosion resistance. With a focus on industrial HVAC devices or storage and containers for agricultural products, its cost effectiveness positions it prominently in budget-sensitive projects without compromising quality.

Alloy 1100:This alloy becomes particularly interesting with its enhanced strength but still maintains considerable ductility, which is crucial for metal forming processes. Aluminum 1100 is often found in food and chemical processing, general fabrication, and ornamental applications. Its easy-to-paint surface caters to those needing aesthetics fused with functionality, ensuring that every finished product holds pristine visual appeal.

Alloy 3003:Known for its superior workability and corrosion resistance, alloy 3003 finds its niche in the manufacturing of cooking equipment, storage tanks, and architectural applications where aesthetics meet performance. This alloy retains the malleability needed to undergo significant shaping without cracking. Sustaining heat deformation and high welding capability affords those in the kitchen design and loft construction with a depth of structural options.

Alloy 5005:This alloy makes its mark primarily within the aesthetic and decorative aluminum sector. Many favor alloy 5005 for anodized finishes, notably loved for its collection of colors that reflect sophistication. Besides its decorative appeal, 5005 also retains an exceptional level of strength combined with good electrical conductivity—making it popular for electrical appliances and building facades alike.

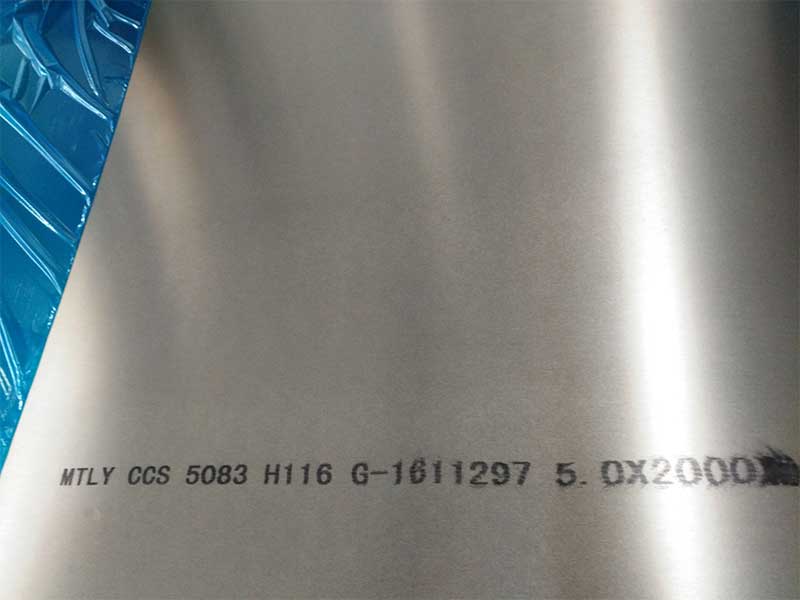

Alloy 5052:Finally, alloy 5052 stands at the forefront of strength in high-stress applications while providing still ly manageable formability. Renowned in marine environments—resisting pitting and corrosion—it finds common usage in shipbuilding. This alloy is invaluable when constructing pressure vessels due to its resistance to fatigue and outstanding weldability.

Practical Insight into Fabrication and Maintenance

the demand and usage of different aluminum alloys means recognizing the ramifications of manufacturing choices. Specific properties mean that some can withstand extreme conditions, while others are primarily for decorative usage. When selecting an alloy, consider both performance and visual appearance.

Additionally, maintenance matters. These mill finish sheets can tarnish without adequate care. While anodized surfaces may protect against corrosion longer, the basic alloys benefit greatly from a simple occasional wash with detergent and warm water to maintain their luster. Also, mindful handling prevents scratches that mar their smooth surface.

https://www.aluminumplate.net/a/mill-finish-aluminum-sheet-1060-1050-1100-3003-5005-5052.html