5086 H116 Aluminium sheet

5086 H116 Aluminium Sheet: The Unsung Hero of Marine and Automotive Industries

When we think about materials that combine lightweight strength with exceptional corrosion resistance, the 5086 H116 aluminium sheet often flies under the radar. Yet, it quietly supports critical components in demanding environments, especially in marine and automotive applications. Let's dive into what makes the 5086 H116 aluminium sheet distinctive and why it has earned a special place in the manufacturing world.

5086 H116 Aluminium Sheet: More Than Just a Number

At first glance, the term "5086 H116" may seem like just technical jargon—so breaking it down will clarify why each part of this designation matters.

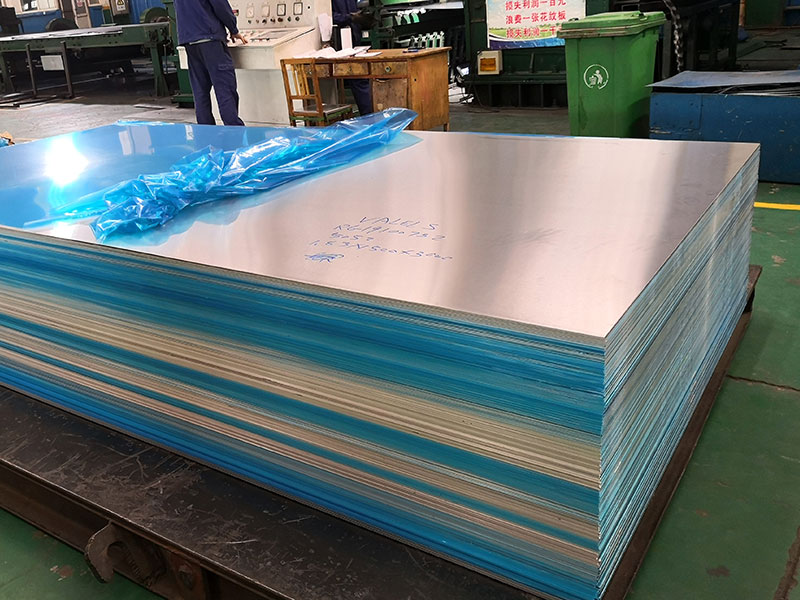

5086 H116 aluminum sheet, with its high magnesium content, presents a unique set of challenges and advantages in our production line. Its excellent formability in the H116 temper makes it a favorite for complex shapes, a boon for our automotive and transportation clients who demand intricate parts. However, this same characteristic requires careful control during stamping and bending operations. Too much force can lead to cracking or tearing, while insufficient pressure results in inconsistent geometries. We've had success mitigating this by implementing specialized tooling with carefully calibrated pressures and incorporating intermediate annealing cycles into our processes for larger, more complex pieces. Furthermore, the inherent strength and weldability are selling points, but require precise control over welding parameters to avoid porosity or other defects that weaken the final product.

The corrosion resistance of 5086 H116 is a double-edged sword. While generally excellent, especially in marine environments, we've learned that improper cleaning or surface treatments prior to further processing can lead to unexpected corrosion issues later in the product lifecycle. Therefore, stringent surface preparation protocols and meticulous quality control checks are vital at every stage, from the initial coil inspection to the final product shipment. A particularly insightful discovery was the correlation between the storage environment of the sheets and their susceptibility to surface imperfections. Maintaining a consistent, dry, and controlled storage area proved crucial in minimizing issues related to surface oxidation and maintaining optimal material quality. This directly translates to better customer satisfaction and

- 5086 refers to the alloy series. It's part of the 5xxx family, meaning magnesium is its primary alloying element. With magnesium content between 4.0% and 4.9%, 5086 alloy offers excellent strength and notable corrosion resistance, especially in saltwater environments.

- H116 is a temper designation focusing on mechanical properties, particularly strain-hardened conditions with tested resistance to corrosion. This tempering specifies that the sheet strikes a compelling balance between durability and formability without additional heat treatment.

What Sets 5086 H116 Aluminium Sheet Apart?

The 5086 H116 aluminium sheet is a stellar choice when metals must endure high stress and exposure to harsh corrosive elements, such as saltwater and marine atmosphere. Its moisture-champion reputation is not accidental:

- Superior Marine Performance: Many shipbuilders use 5086 H116 because it resists pitting and stress corrosion cracking—a severe hazard when lightweight metals meet seawater.

- Strength and Flexibility: It has commendable tensile strength (about 31 ksi / 215 MPa) and can be formed into complex profiles without compromising integrity. Those attributes make automotive and transportation designers happy.

- Defense and Aerospace Applications: Its dependable combination of toughness and corrosion resistance meets requirements in specialized transports, boat hulls, armored vehicles, and aircraft components.

Unique Perspective: Where Supply Chain Meets Sustainability

In today’s world, evaluating materials should extend beyond immediate performance—to embrace eco-friendliness and sustainability in suppliers and recycling potential.

5086 H116 aluminium sheet is highly recyclable without quality loss, making it an environmentally advantageous material choice among metals. Industries leveraging this fact reduce waste footprint alongside maintaining high product lifespan. Moreover, advancements in aluminum recycling ensure that scrapped 5086 sheets rejoin future manufacturing loops without demanding costly or energy-intensive processes.

Technical Clarity: The Science Behind H116 Temper

The temper “H116” may seem less talked about compared to T-temper products, but here's why manufacturers rely on it:

- The “H” designates strain hardening, so the material gains strength through cold working rather than heat.

- The “1” series indicates carefully controlled processes to achieve known tensile properties, as opposed to arbitrary annealed states.

- The “16” confirms the material’s resistance to corrosion anticipated in actual use, validated in salt-spray or exposure tests.

Applications That Define Success Stories

Because of these impress compelling combinations, 5086 H116 aluminium sheets commonly feature in:

- Boat hull plating and marine superstructures.

- Truck and trailer bodies requiring durable, corrosion-resistant walls.

- Protective military vehicle armor due to light weight yet tough resilience.

- Architectural façades exposed to salty sea air and severe weather extremes.

https://www.aluminumplate.net/a/5086-h116-aluminium-sheet.html