0 2mm polished mirror aluminum

Elevating Aesthetics and Functionality with 0.2mm Polished Mirror Aluminum: A Perspective Beyond Reflection

In the world of modern design and manufacturing, the pursuit of perfection often leads to the exploration of innovative materials that combine both visual appeal and functional performance. Among these, 0.2mm polished mirror aluminum emerges as a standout contender, not just for its striking appearance but for the unique advantages it offers when appreciated from a distinct perspective—the realm of ultra-thin, high-precision applications.

The Thin-Line Brightness: A Material Unveiled

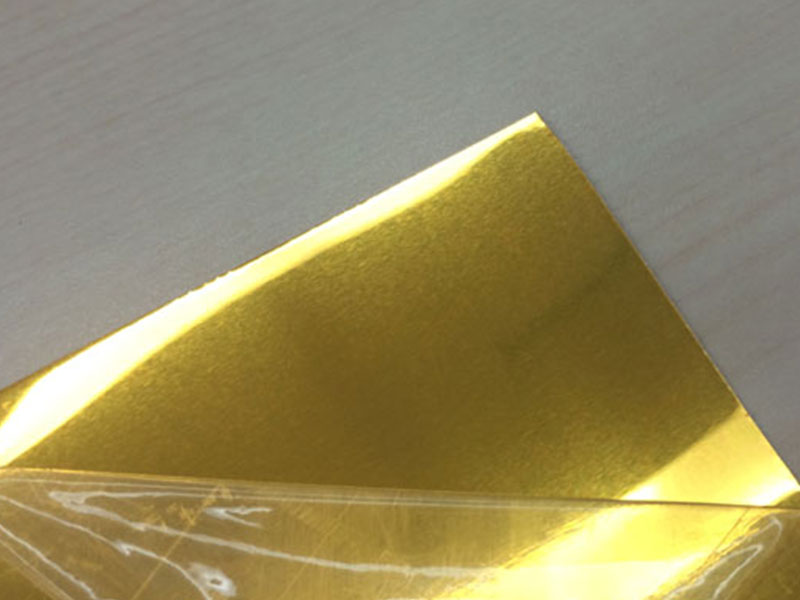

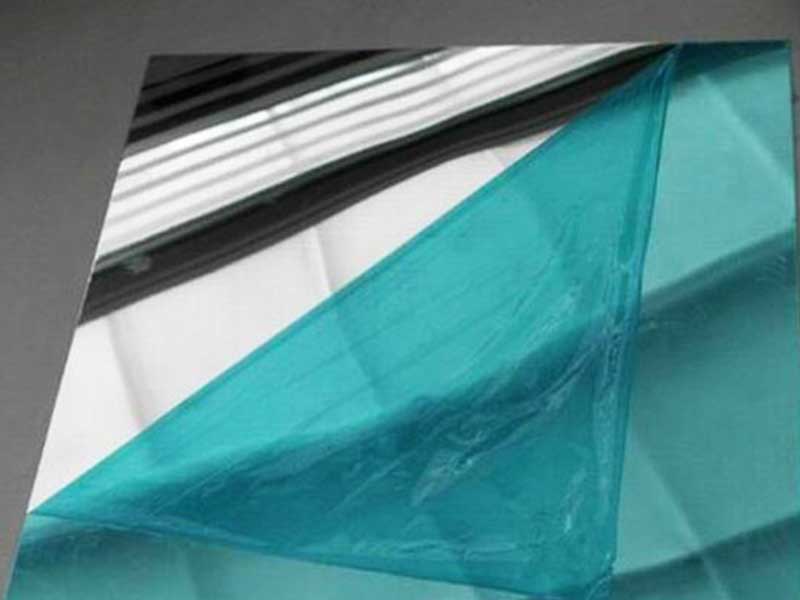

Polished mirror aluminum typically shines in applications demanding a mirror-like finish that amplifies aesthetics. The 0.2mm thickness—a fraction of a millimeter—transcends traditional boundaries by integrating structural resilience with minimal weight. This slender profile transforms what might be thought of as a simple metallic sheet into a flexible, reflective canvas capable of bending and conforming with precision, opening new horizons for designers and engineers alike.

Beyond Beauty: Functional Flexibility in Design

From a vantage point grounded in practical expertise, the thinness of 0.2mm mirror aluminum facilitates creative innovations that are difficult to achieve with bulkier counterparts. For example, in architectural facades, a flat yet flexible mirror aluminum sheet can be tailored into curved structures, allowing architects to craft dynamic, nuanced surfaces that reflect light in captivating ways. Its mirror polish, applied to such a thin material, amplifies ambient light effects—brightening interior spaces or elevating metallic exteriors with a high-gloss, mirror finish.

Applications Where Thinness Meets Performance

Lighting and Decorative Panels: The ultra-thin profile creates sleek, lightweight decorative elements that maximize reflector efficiency and aesthetic purity. Enhanced luminance distribution can be achieved with minimal material bulk.

Electronics and Display Components: As electronic devices trend toward slimmer profiles, 0.2mm polished mirror aluminum embodies an ideal shielding or decorative layer—combining lightweight nature with reflective qualities required for optical clarity.

Aerospace and Automotive Interiors: Reduced weight components—like interior trim—designated with polished mirror aluminum elevate the luxury factor, while their thinness contributes to overall weight savings,.a critical parameter for energy efficiency.

Manufacturing Insights and Considerations

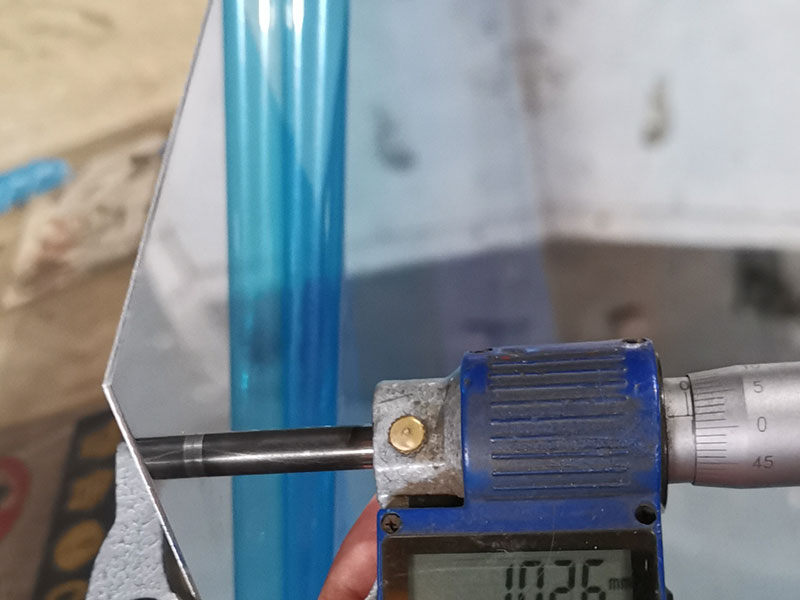

Achieving a pristine, mirror-polished finish on 0.2mm aluminum unfolds multiple technical nuances. The aluminum alloy choice, typically 1050, 1060, or 1100 series—known for excellent ductility and high purity—is crucial. Its malleability allows for fine polishing without risk of cracking or deformation, which becomes more critical at such a slender gauge.

Moreover, attention to surface treatment processes—polishing, buffing, and protective coating—is vital for maintaining the mirror effect and preventing wear or tarnishing. From a genuine practical standpoint, the thinness necessitates carefully controlled handling and manufacturing protocols to prevent creases or surface scratches.

Sustainability and Application Longevity

The eco-conscious financier might raise concerns regarding durability. While ultra-thin sheets naturally pose challenges in handling, advances in protective coatings—such as clear lacquers or anodic layers—further enhance their life span. Their high reflectivity also means they can be efficiently cleaned and maintained, promising long-term visual and functional performance.

https://www.aluminumplate.net/a/0-2mm-polished-mirror-aluminum.html