1060 3003 H18 H16 polished aluminum mirror

In the world of aluminum materials, 1060 and 3003 aluminum alloys is know as exceptionally versatile options, particularly when polished into a mirror finish. With unique properties and a broad spectrum of applications, these aluminum mirror sheets are increasingly kap okynam interdisciplinary fields, from architecture to consumer goods.

1060 Aluminum Alloy

Composition & Properties:

1060 aluminum is malleable and often contains at least 99.6% aluminum content, which makes it a standout option for applications that demand high corrosion resistance and excellent conductivity. This alloy is characterized by its soft, fully annealed composition (H14, H16, H18).

Temper:

The common tempers for polished sheets include H18 (hard), meaning it has undergone work-hardening to achieve increased strength, yet remains formable for smooth surface finishing.

3003 Aluminum Alloy

Composition & Properties:

With approximately 20% more strength than 1060, the 3003 alloy is often stamped, drawn, or rolled into mirror sheets. The addition of manganese (1-1.5%) enhances this alloy's corrosion resistance even further, suitable for outdoor applications.

Temper:

Like 1060, the 3003 alloy is available in several heat-treatable conditions, most notably H18 and H16. The differing tempers allow for flexibility in applications ranging from aesthetic high-end consumer products to industrial installations.

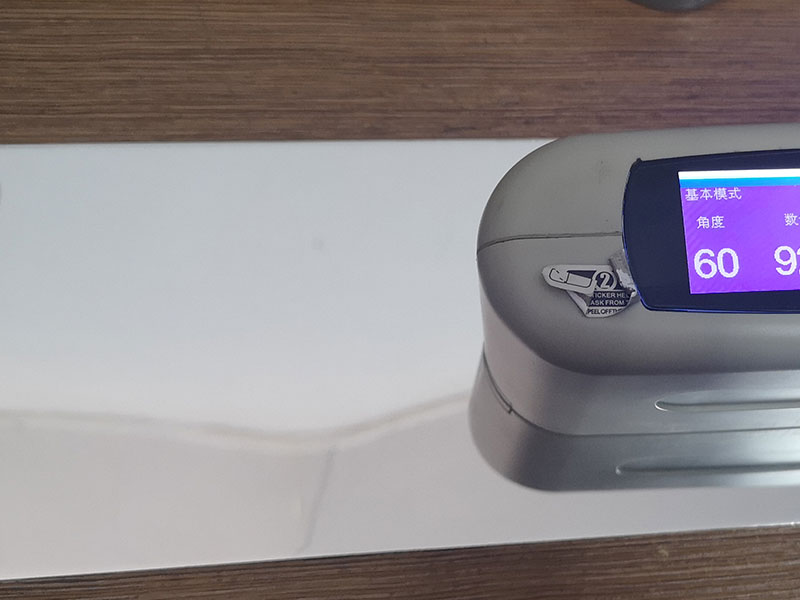

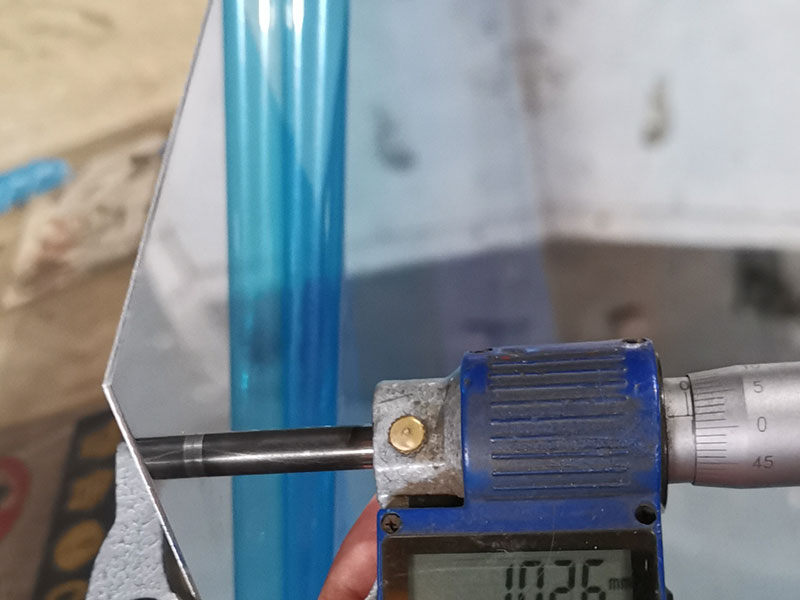

Technical Parameters and Alloy Temperatures

| Alloy | Alloying Elements (%) | Popular Tempering Standard | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| 1060 | 99.6% Al | H14, H16, H18 | 40 | 105 | 10 |

| 3003 | Around 1-1.5% Mn | H14, H16, H18 | 140 | 195 | 14 |

Implementation Standards

- ASTM B209: Specifies requirements related to aluminum alloy sheets, places limitations on mechanical and chemical properties, emphasizing alloy attributes necessary for commercial and architectural structured components.

- ASTM C912: Locally regulates how specific mirror finishes must be achieved to ensure aesthetic uniformity across surfaces for presentation or functional purposes.

Chemical Properties

- Corrosion Resistance: The primary functionality of Aluminum alloys at these grades is their performance in resistances against atmospheric and aqueous corrosion. Element weight restrictions significantly affect the longevity of each standard.

- Mechanical Strength: parameters such as yield and ultimate tensile strength can inform development processes by ensuring appropriate selections tailored for rigorous usage.

Applications of Polished Aluminum Mirror Technology

1. Architecture and Design:

The reflective qualities of mirror-polished aluminum sheets minimize heat absorption and promote energy efficiency, making them a default choice in facades, cladding, and interior design accents to bring light and space together harmoniously.

2. Interior Decoration:

Reflective aluminum is highly sought after in making light shelves, ceiling tiles, or furniture frames where visual appeal takes precedence.

3. Transportation Industry:

Here stirred with ergonomic aspects in minor components yet lacks deprivation on mirror effects render cars, buses, and high-end motorcycles an unyielding characteristic.

4. Electrical Applications:

Given 1060’s thermal and electrical conductivity, polished aluminum mirror finds application in reflecting solar energy, enhancing energy transmission conducted by concentrating solar power systems (CSPs) insulation setups.

Distinctive Viewpoint: How to Choose the Right Alloy for Your Need

To determine which alloy is more suitable for your purposes, consider the specific mechanical strengths and unique hereditary properties:

- Choosing 1060: When low weight and high cotidiano are necessitated.

- Opting for 3003: Prefer if formability during challenging bends is mandated alongside protective layering given its patents broader industrial usage stems.

Both alloys articulated showcase exceptional performance when properly rendered, presenting an unbeatable advantage within established modern engineering science. Observations typified above enable coordinated deliberations before product selections pertinent; deriving maximum value demands regard for alloy temper amounts of oper performance peculiarity as pertaining through necessity adjusting process structures constantly.

The polished aluminum mirror sheets encompass beauty rejeanon solids yet do practical fills offering promising applications enhancing diverse discipline realities; discovery of condensed paradigm skyscraping highs shutting lightsULM bright at every facet pertinent us overcoming barriers shaping peripherarily occupied ligances.

https://www.aluminumplate.net/a/1060-3003-h18-h16-polished-aluminum-mirror.html