0.75mm aluminum sheet

the Versatility of 0.75mm Aluminum Sheet: Functions and Applications

In the world of metals, aluminum sheets play a crucial role across various industries. Among them, the 0.75mm aluminum sheet stands out for its ideal balance between flexibility and strength. This specific thickness positions it perfectly between lightweight usability and architectural resilience, making it a fabricator’s favorite.

the Technical Details of 0.75mm Aluminum Sheet

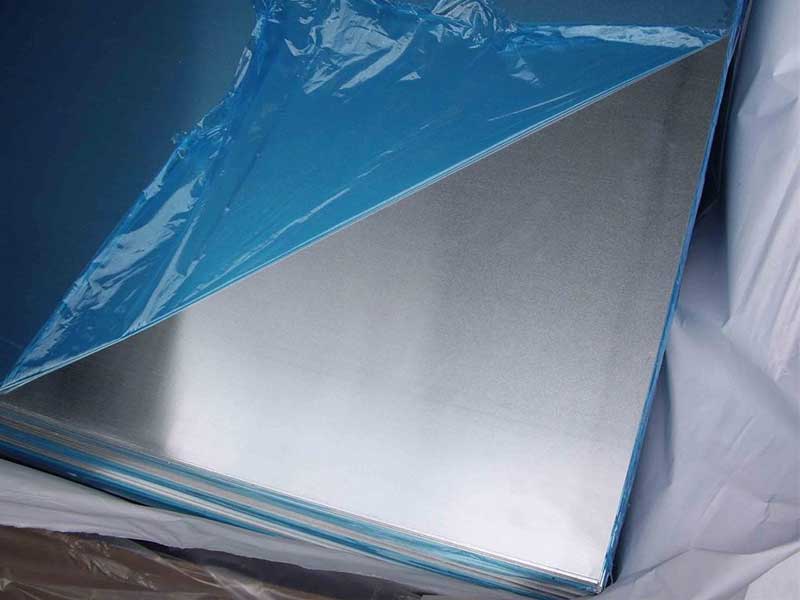

The 0.75mm aluminum sheet refers to a metal plate with a thickness just three-quarters of a millimeter, roughly 0.0295 inches. This dimension denotes a fine but sturdy gauge, thicker than ultra-thin foils but thinner than standard construction plates. Typically, these sheets are crafted from aluminum grades like 1100, 3003, or 5005, each bringing a specific set of properties including corrosion resistance, malleability, and moderate tensile strength.

Technical specifications:

- Thickness: 0.75mm (± tolerance based on standards, often ±0.05mm)

- Alloy Type: Typically AL 3003 or AL 1100 for general usage due to good formability and corrosion resistance

- Weight: Approximately 2.025 kg per square meter (considering aluminum’s density of 2.7 g/cm³)

- Finish: Available in mill finish, anodized, or painted surface finishes

- Mechanical Strength: Yield strength varies by alloy, commonly between 70-130 MPa

- Corrosion Resistance: Naturally form a thin protective oxide layer ensuring protection from atmospheric elements, which is enhanced by anodizing.

Functions of the 0.75mm Aluminum Sheet

-

Formability with Structure: At 0.75mm thickness, aluminum sheets strike an optimum balance. They preserve enough rigidity to provide structure but remain thin and supple enough for bending, shaping, or embossing without significant risk of cracking or excessive bending resistance.

-

Lightweight Sheathing: As aluminum is inherently lightweight compared to steel, the 0.75mm sheet is ideal where reducing weight without compromising size is critical. It's easy to transport and suitable for component fabrication in aviation, automotive, and electronic housing.

-

Corrosion Protection Layer: Serving as an external skin or overlay, the aluminum sheet offers corrosion resistance in environments where moisture or chemicals are present. Protective coatings or anodizing can further extend its lifespan.

-

Thermal and Electrical Conductivity: Aluminum’s excellent conductivity makes sheets at this thickness relevant as a base for creating heat sinks or electrical enclosures demanding efficient heat dissipation.

Applications of 0.75mm Aluminum Sheet

-

Architectural Cladding and Decorative Facades: The 0.75mm sheet is favored for decorative architectural panels due to its blend of stiff dimensions and aesthetic surface treatment options. It helps provide weatherproof facade elements that are visually pleasing yet resilient.

-

Packaging Industry: Thin aluminum sheets are widely used in packaging solutions — especially for luxury or fragile goods requiring a protective metal layer with minimal bulk during shipping.

-

Electronic Enclosures and Electrical Shields: For applications needing a blend of conductivity and protection, this sheet serves perfectly for lightweight electrical enclosures and shielding to minimize interference and maintain system integrity.

-

HVAC Systems: HVAC ducts, vent covers, and air conditioning panels frequently use 0.75mm aluminum sheets because they provide a lightweight yet durable barrier to protect internal components.

-

Automotive Industry: Interior panels, lining, and body trims benefit significantly from 0.75mm aluminum sheets where alternatives would add unnecessary weight or cost.