Aluminum sheet texture

Aluminum Sheet Texture: A Blend of Functionality and Aesthetic Appeal

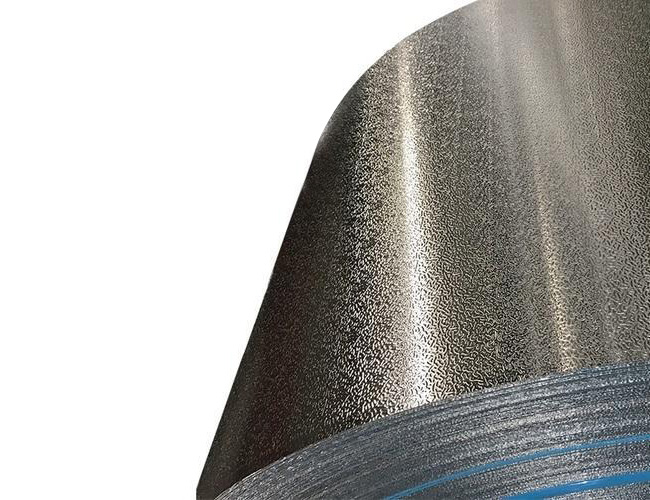

When we think about aluminum sheets, the first thing that often comes to mind is their sleek, smooth surface, commonly seen in construction, automotive, or kitchen appliances. However, diving deeper into the world of aluminum, you discover a fascinating range of textures designed to serve both technical purposes and aesthetic desires. Among these, aluminum sheet texture stands as a crucial factor that balances performance, appearance, and longevity.

The Science Behind Aluminum Sheet Textures

Aluminum sheets might appear simple at first glance, but they come with an array of surface textures influenced by various manufacturing processes. From smooth brushed finishes to the popular stucco embossed aluminum sheets, these textures impact not only how the sheets look but also how they interact with their environment.

-

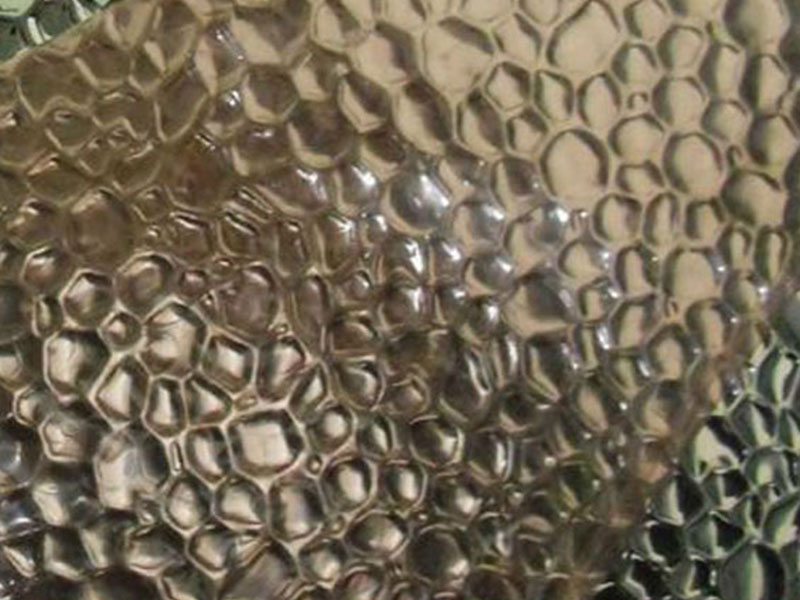

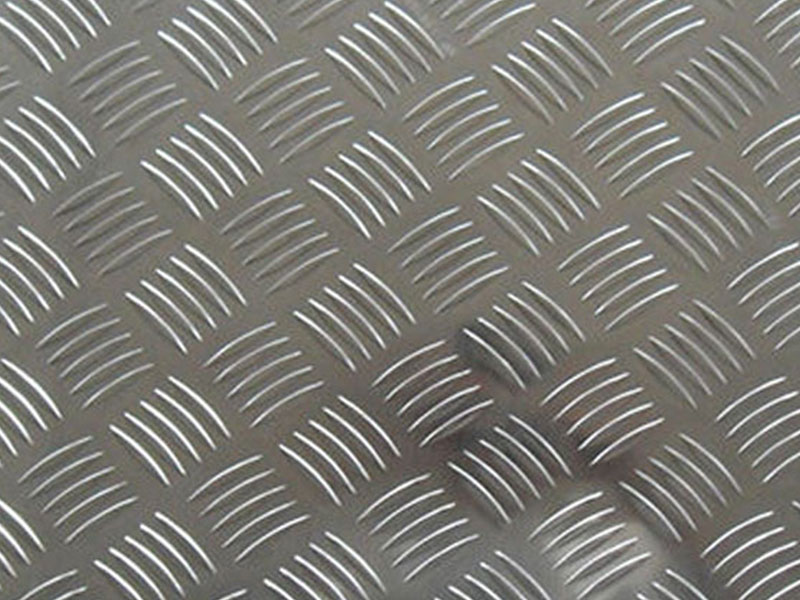

Embossing Process: Embossing aluminum involves pressing a pattern into the sheet’s surface, which creates intricate textures. This is more than decorative — it enhances the material’s grip, reduces glare, and hides scratches. For example, stucco embossing gives a patterned, slightly raised surface reminiscent of plaster or concrete walls, bringing practical slip-resistance and a unique visual element that transforms the sheet from an industrial metal to a decorative material.

-

Surface Protection: Textures help aluminum sheets endure harsh weathering effects. The embossed patterns make it harder for dirt and debris to adhere, promoting self-cleaning qualities with rain or washing. Furthermore, such textures can reduce fading caused by prolonged sun exposure by diffusing the ultraviolet light instead of having it absorbed evenly.

Why Texture Matters in Aluminum Sheets

-

Functional Durability: In architectural applications, dry professionalism meets creative appearance when opting for textured aluminum. For instance, the stucco embossed sheet adds excellent anti-slip properties on roofing or ceiling areas prone to moisture, thus making it safer without sacrificing aesthetic appeal.

-

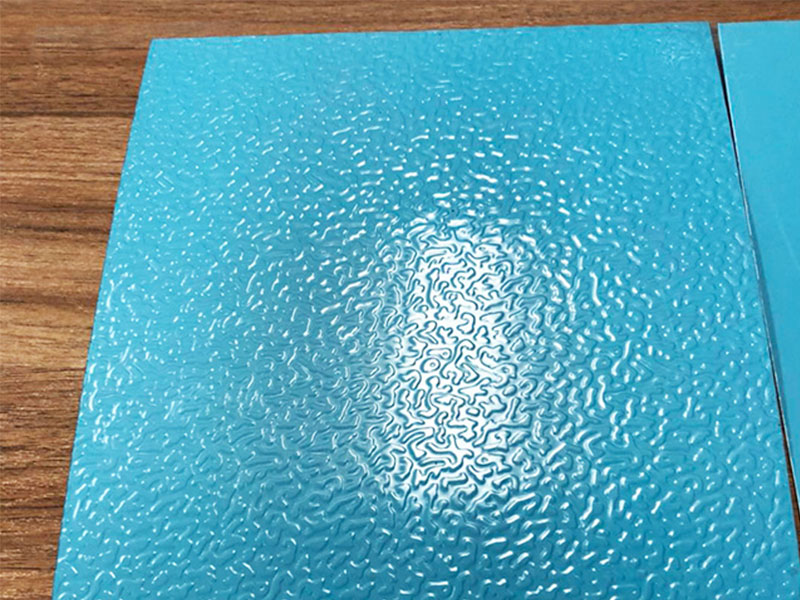

Brand Differentiation: Businesses investing in building facades or vehicles often look for materials that set them apart aesthetically. Embossed aluminum sheets offer subtle yet noticeable personalization, moving beyond plain metallic looks to embody brand identity and innovation.

-

Maintenance and Longevity: The fine ridges and patterns in textures reduce the chances of scratches being obvious, extending the sheet’s showroom-quality look far into years of use—minimizing maintenance requirements, especially in high-traffic, outdoor areas.

-

Thermal Performance: While aluminum sheets conduct heat effectively, embossed surfaces can improve heat dissipation due to increased surface area, helping buildings maintain more stable interior temperatures with enhanced ventilation dynamics.

Stucco Embossed Aluminum Sheet: A Unique Texture with Multiple Benefits

Among the array of textured finishes, the Stucco Embossed Aluminum Sheet stands out. Its robust yet elegant footprint combines a rough plaster-like visual appeal with corrosion-resistant, lightweight aluminum engineering.

Whether for architectural cladding, decorative wall panels, or environmental control surfaces, this particular textured sheet strikes an ideal fusion of durability and style. Its tactile feel also adds an unparalleled sensory experience where tactile reception matters, such as handrails or public installations.

Final Thoughts

The value of aluminum sheet texture, especially embossed types like stucco finish, transcends mere visual interest. It addresses practical needs such as non-slip properties, weather resilience, maintenance ease, and even thermal efficiency. By embracing textured aluminum sheets, architects, designers, and manufacturers unlock a versatile material capable of elevating both form and function across countless applications.