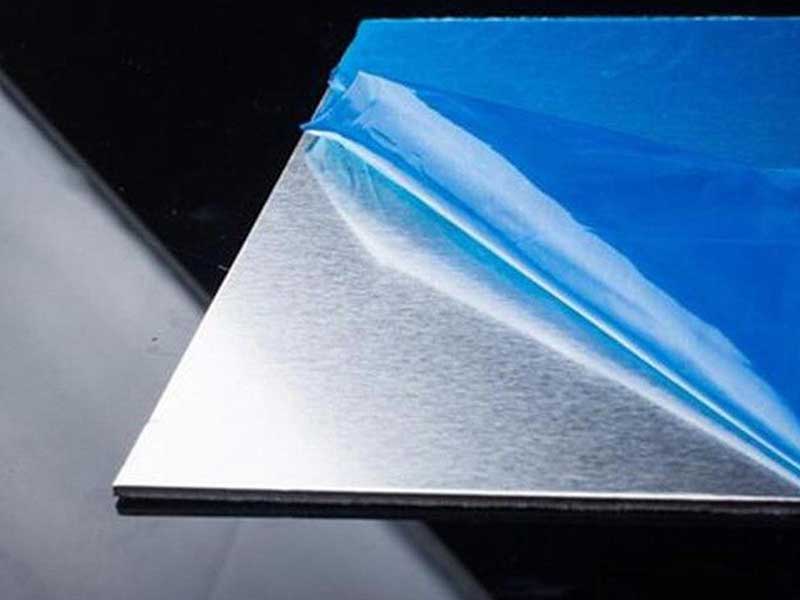

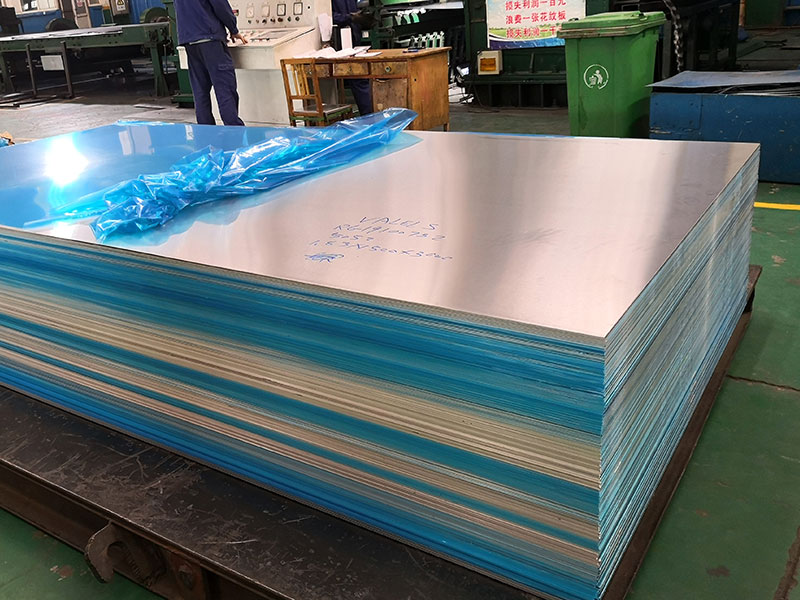

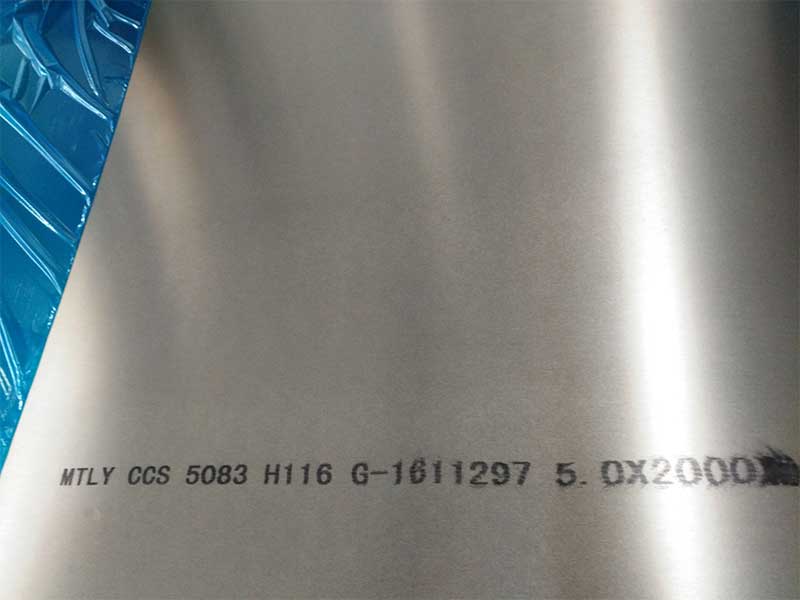

Alloy 6061 6063 Aluminium Sheet

Aluminium alloys have become synonymous with innovation in material science, particularly in the construction, automotive, and aerospace industries. Among a plethora of alloys available in the marketplace, Alloy 6061 and 6063 often emerge as go-to materials, especially for sheet-like applications.

Two Distinct Titans of Aluminium Alloys

While both alloys are classified under the 6xxx series of aluminium alloys, they serve different needs and highlight unique properties.

Alloy 6061: Often hailed for its workability and strength, 6061 features a balanced combination of corrosion resistance and mechanical properties. It contains magnesium and silicon, contributing to its well-rounded characteristics. Notably, its ability to be extruded into complex shapes makes it exceptionally popular in structural applications and manufacturing automotive and aerospace components.

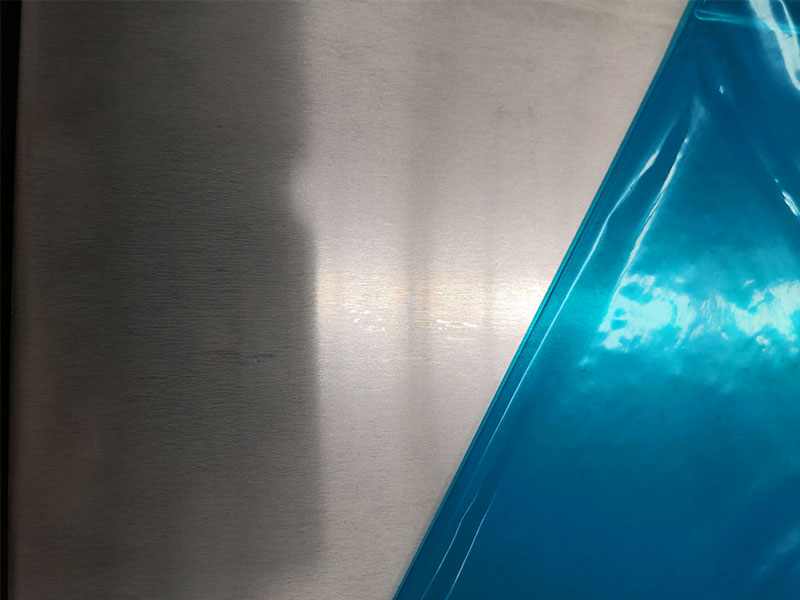

Alloy 6063: Think of 6063 as the graceful counterpart to 6061. Primarily designed for architectural fabrication, this alloy provides a highly refined surface finish and is favored for making visually appealing extrusions. Its excellent die compatibility and uniform grain growth allow it to be used effectively in decorative applications, not to mention its intrinsic corrosion resistance.

Synergetic Applications

One of the intriguing aspects of these alloys is their extensive, though often overlooked, synergy when utilized together. Mixing and matching these alloys in contemporary designs can yield exceptional results. For instance, an architectural project might see the elegant façades crafted from 6063 sheets framed with the robust strength of 6061 structural elements.

Taking a step back, imagine a beautifully designed public library. The architectural prowess utilizing 6063 for its facades ensures a striking aesthetic appeal while harmonizing with 6061 infrastructure that stands strong against environmental challenges. Through this lens, these alloys can be perceived as instruments shaping modern environments, blending artistry with engineering resilience.

Sustainability and Efficiency

Viewed from the perspective of sustainability, both alloys resonate with the growing demand for eco-friendly materials. The recyclability of aluminium is a significant attribute, pushing both 6061 and 6063 into the limelight. The manufacturing energy required for recycling aluminium is significantly less than that needed for producing it from ore, allowing for reduced carbon footprints—a pivotal concern in today's climate-conscious world.

Moreover, both alloys lend themselves beautifully to lean manufacturing and minimal waste production strategies. In an industry increasingly criticized for resource depletion and inefficiency, choosing alloys like 6061 and 6063 mean bankable investment in sustainability as much as functionality—creating extraordinary structures without hefty environmental repercussions.

Problem Solving: Real-World Scenarios

Innovative usage of Alloy 6061 and 6063 is paramount when addressing engineering challenges. Consider the case of a telecommunications company striving to enhance the reliability of street communications gear in varying urban climates. Designers were able to harness the properties of 6063 for the housing of communication nodes thanks to its aesthetic appeal, though faced with corrosion and structural stress. They opted for a reinforced framework that incorporated 6061, ultimately enhancing durability and reliability over time.

The mission was accomplished without sacrificing design. Such scenarios underscore the flexible problem-solving capabilities presented by these alloys. They communicate an essential message—innovation begins with the right material choice, emphasizing that your project can, indeed, embody durability and aesthetic sophistication harmoniously.

https://www.aluminumplate.net/a/alloy-6061-6063-aluminium-sheet.html