1061 polished aluminum mirror sheet

1061 polished aluminum mirror sheet is a high-purity aluminum product engineered for exceptional reflectivity, clean surface aesthetics, and stable formability. Through precision rolling, controlled annealing, and mirror-grade polishing, 1061 mirror sheet delivers a bright, near-glass visual effect while keeping the lightweight, corrosion resistance, and fabrication flexibility that aluminum is known for. It is widely selected for lighting reflectors, decorative panels, interior trim, signage, and optical-style components where a premium mirrored finish matters.

For customers who need fast evaluation: 1061 mirror aluminum sheet is primarily chosen for surface brilliance, easy forming, and consistent reflectance, especially in indoor or mild outdoor environments with proper protection.

What Makes 1061 Mirror Sheet Different

1061 belongs to the 1xxx series, meaning it is dominated by aluminum content with only small additions of silicon and iron. This creates a material with strong conductivity, excellent corrosion resistance, and very good ductility. When processed into a mirror finish, the alloy's purity helps produce a high-luster surface with good uniformity across large areas.

features at a glance

| Feature | Customer value | Typical impact in use |

|---|---|---|

| Mirror-grade polished surface | Premium appearance, high reflectivity | Ideal for decorative, lighting, and display panels |

| High-purity aluminum base | Stable corrosion resistance, high conductivity | Reliable indoor performance; good heat dissipation |

| Excellent ductility | Easier bending, rolling, forming | Suitable for curved reflectors and trim parts |

| Low density | Lightweight assemblies | Reduced shipping cost and easier installation |

| Smooth surface base for coating/lamination | Better coating adhesion and visual consistency | Supports protective films, anodizing, and clear coats |

Common Applications

1061 polished mirror sheet is commonly used where visual quality and consistent reflection are more important than high structural strength.

| Application area | Typical products | Why 1061 mirror works well |

|---|---|---|

| Lighting & illumination | Lamp reflectors, luminaire inserts, LED housings | High reflectance; easy forming into reflector geometries |

| Decoration & architecture | Interior panels, ceiling trims, elevator décor | Bright mirror look with lightweight installation |

| Signage & display | Retail displays, logo backplates, exhibition panels | Clean finish; easy cutting and routing |

| Consumer goods | Appliance trim, cosmetic components, casings | Premium appearance; workable for mass production |

| Thermal & reflective solutions | Heat reflection shields (non-structural), radiant barriers | Aluminum reflectivity + corrosion resistance |

Note: For harsh outdoor exposure or highly abrasive environments, mirror sheet is typically paired with protective coating, anodizing, or lamination to preserve gloss and reduce surface damage.

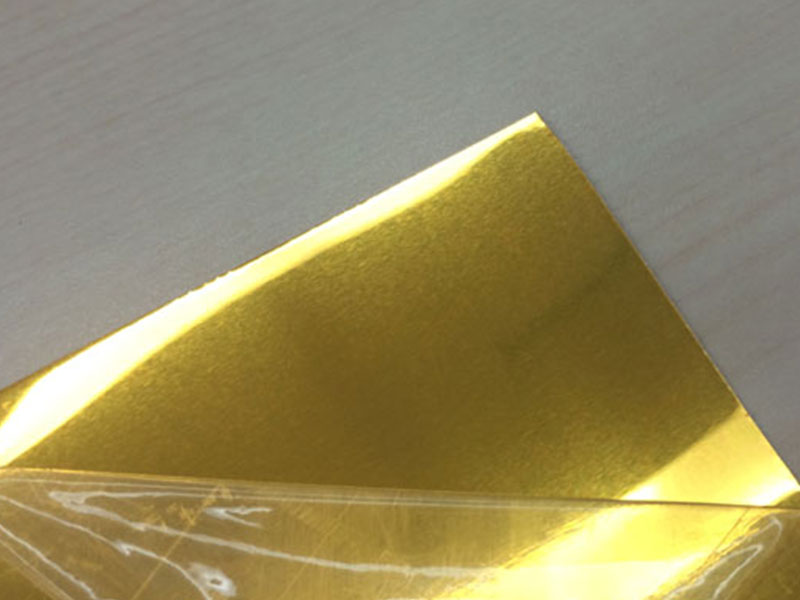

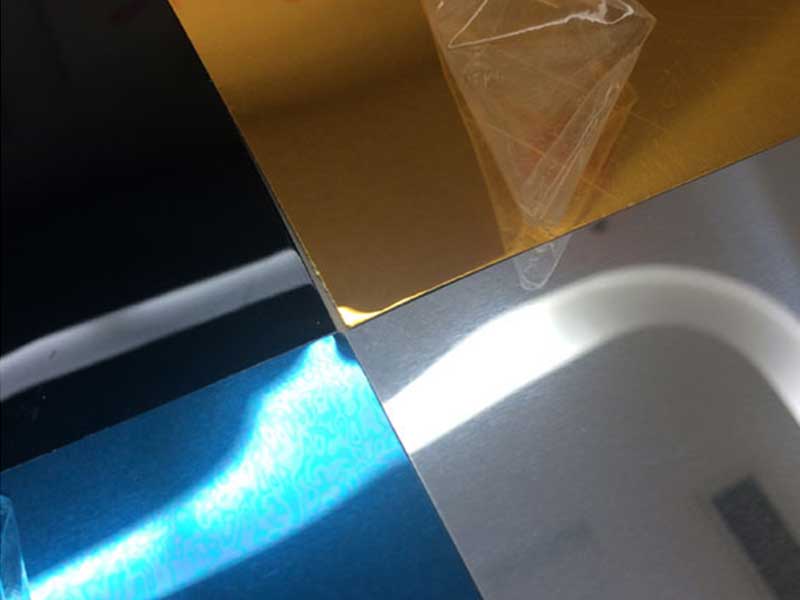

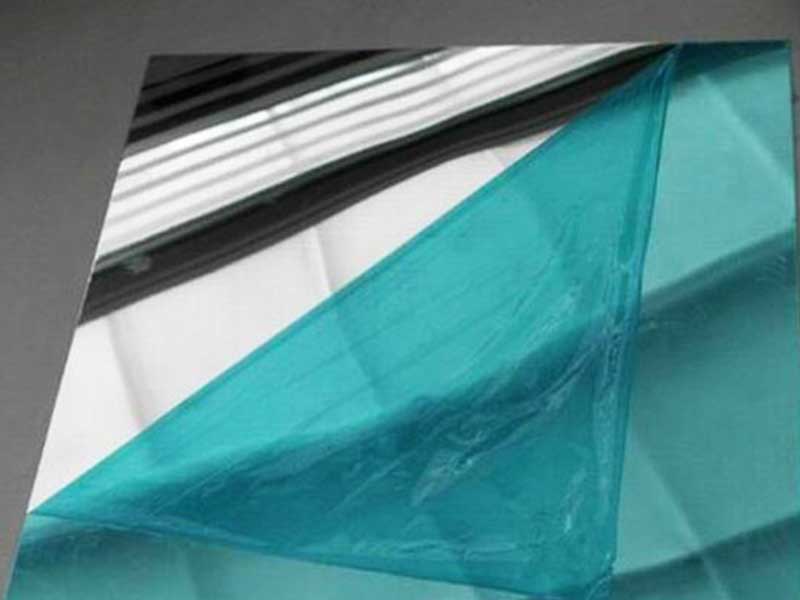

Surface Quality and Finish Options

Mirror aluminum is not only about brightness; it is about image clarity, surface uniformity, and process stability. Customers often specify mirror grade by reflectivity targets and allowable surface defects.

| Item | Typical offering (customizable) |

|---|---|

| Mirror finish type | Polished mirror, bright mirror, super mirror (by process route) |

| Surface protection | PE/PVC film (single or double side), interleaving paper |

| Side options | Single-side mirror / double-side mirror |

| Coating compatibility | Clear coat, color coating, lamination (subject to process validation) |

| Appearance control | Tight control on waviness, roll marks, pinholes, and scratches (grade-defined) |

Chemical Composition (Typical, 1061 Alloy)

1061 is a high-purity aluminum alloy. Exact limits depend on standards and mill practice; values below are presented as typical composition ranges used for production control and customer reference.

| Element | Typical content (wt.%) |

|---|---|

| Al | Balance (high purity) |

| Si | ≤ 0.25 |

| Fe | ≤ 0.35 |

| Cu | ≤ 0.05 |

| Mn | ≤ 0.03 |

| Mg | ≤ 0.03 |

| Zn | ≤ 0.05 |

| Ti | ≤ 0.03 |

| Others (each) | ≤ 0.03 |

| Others (total) | ≤ 0.10 |

Temper Options and Forming Behavior

Mirror sheet is supplied in tempers that balance flatness, gloss retention, and formability. The final selection depends on whether the part will be deeply formed, lightly bent, or simply mounted flat.

| Temper | Typical condition | Formability | Typical use preference |

|---|---|---|---|

| O (Annealed) | Fully soft | Excellent | Deep drawing, tight-radius forming, complex shapes |

| H12 / H14 | Strain-hardened (quarter/half hard) | Good | General bending, good flatness, moderate strength |

| H16 / H18 | Harder strain-hardened | Fair | Panels needing stiffness; less tight bending |

| H22 / H24 | Hardened + partially annealed | Very good | Balanced forming and strength; stable surface for finishing |

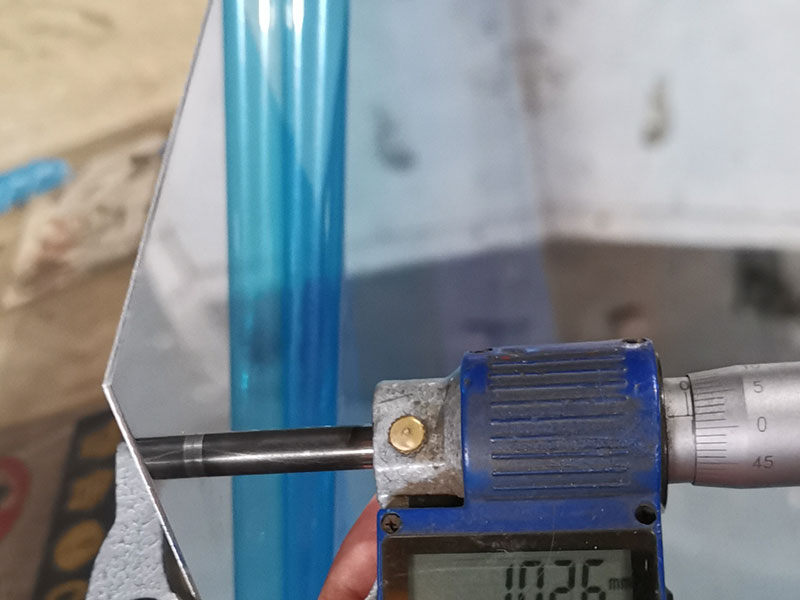

Technical Specifications (Supply Range)

Supply ranges vary by mill capability and polishing line configuration. The table below reflects common commercial ranges for mirror-grade sheet.

| Parameter | Typical range |

|---|---|

| Thickness | 0.20–3.00 mm |

| Width | 200–1600 mm |

| Length | 500–6000 mm (sheet) / coil available |

| Flatness | Controlled for mirror applications (grade-defined) |

| Surface roughness (Ra) | Polishing-dependent, commonly low Ra for mirror clarity |

| Reflectivity (visible) | Commonly 80%–95% depending on mirror grade and coating |

| Protective film | Optional, recommended for logistics and fabrication |

| Edge condition | Mill edge or slit edge |

Typical Mechanical Properties (Reference)

Mechanical properties depend strongly on temper and thickness. Values below are typical guidance ranges for customer selection and are not a substitute for certified test reports.

| Property | O | H14 | H24 |

|---|---|---|---|

| Tensile strength (MPa) | 60–90 | 90–120 | 80–110 |

| Yield strength (MPa) | 20–35 | 35–60 | 30–55 |

| Elongation (%) | 25–35 | 6–12 | 10–18 |

| Brinell hardness (HB) | 18–28 | 30–40 | 25–38 |

Performance Notes Customers Care About

| Topic | Practical guidance |

|---|---|

| Scratch sensitivity | Mirror surfaces show handling marks easily; film protection and clean gloves are strongly recommended |

| Corrosion resistance | Excellent in indoor/mild environments; avoid alkaline cleaners and chloride-rich exposure |

| Forming | Use clean tooling and appropriate lubrication to prevent surface imprinting |

| Cutting & routing | Sharp tools minimize burrs and reduce edge micro-tearing that can propagate scratches |

| Cleaning | Neutral pH cleaners + soft microfiber; avoid abrasive pads to preserve reflectivity |

Packaging and Quality Control (Typical)

| Item | Standard practice |

|---|---|

| Surface protection | PE/PVC film + corner guards |

| Packing | Export wooden pallets/crates, anti-moisture wrapping |

| Traceability | Heat/coil ID, inspection records, optional material certs |

| Inspection focus for mirror | Gloss uniformity, surface defects, waviness, thickness tolerance, film adhesion |

Why Choose 1061 Polished Aluminum Mirror Sheet

1061 mirror sheet is a strong value choice when the priority is high reflectance and premium appearance paired with the processing friendliness of a high-purity aluminum. It performs especially well in lighting, interior decoration, and display projects, where bright reflection, low weight, and clean surface quality help products look sharper and install easier.

1061 polished aluminum mirror sheet is a high-purity 1xxx series aluminum sheet with a bright mirror finish, excellent corrosion resistance, and strong formability. It is widely used for lighting reflectors, decorative panels, signage, and interior architectural trim. Available in multiple tempers and common thickness/width ranges, 1061 mirror aluminum offers high reflectivity, smooth surface quality, and lightweight performance, with optional protective film and coating compatibility for improved durability.

https://www.aluminumplate.net/a/1061-polished-aluminum-mirror-sheet.html