1mm 2mm thick aluminium sheet alloy 5154 A H28

At first glance, aluminum sheets may seem like simple materials. However, a closer inspection reveals their pivotal role in various industries. Among them, the 5154 A H28 alloy stands out for specific applications, bringing robust benefits to the table.

Alloy 5154

The 5154 aluminum alloy is a member of the 5000 series, which is primarily known for its excellent corrosion resistance and good weldability characteristics. The unique properties of 5154 alloy arise from its addition of magnesium, which enhances strength while maintaining malleability. Specifically, in the H28 temper, the alloy undergoes a strain-hardened and partially annealed process, giving it a balance of strength and ductility. Imagine an engineering marvel that holds its own under considerable stress while still being easy to shape and handle.

Properties

| Property | Value |

|---|---|

| Alloy Designation | 5154 |

| Thickness | 1mm, 2mm |

| Temper | H28 |

| Tensile Strength | 310 MPa |

| Yield Strength | 220 MPa |

| Modulus of Elasticity | 69 GPa |

| Electrical Conductivity | 34% IACS |

| Corrosion Resistance | Excellent |

| Weldability | Good |

Applications and Usability

Alloy 5154 H28 is particularly suited for demanding environments, making it a preferred choice in marine, automotive, and industrial sectors. Its noteworthy attributes compel designers and engineers to opt for this aluminum alloy, especially under conditions where resistance to seawater corrosion is crucial.

For instance, the 5154 alloy serves as an excellent candidate for fabricating parts in boats and ships. Its reliable corrosion resistance ensures longevity—even when constantly exposed to harsh marine environments.

The automotive industry also finds this alloy useful for components like structural panels and fuel tanks, where safety and durability are paramount. The good weldability allows for streamlined manufacturing processes, leading to higher productivity and less material waste.

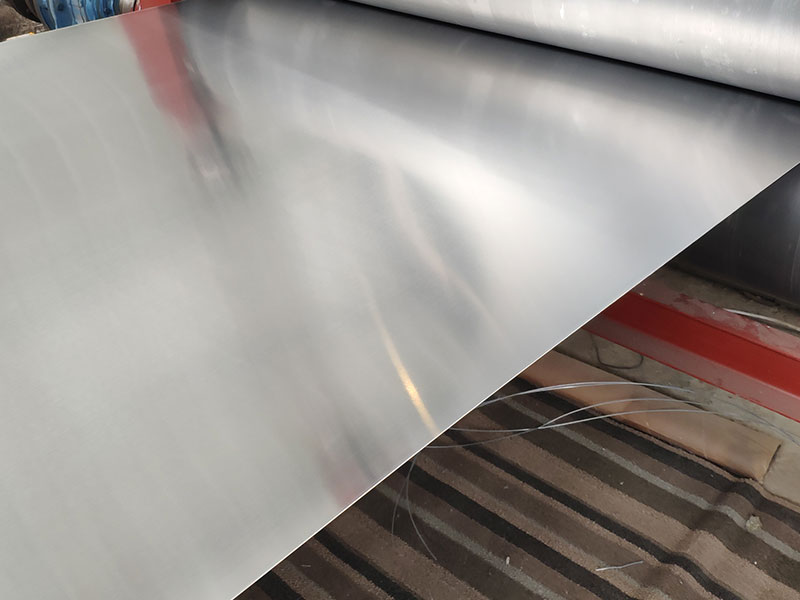

Thickness Variances: 1mm vs. 2mm

Choosing between a 1mm and a 2mm aluminum sheet may depend on your specific project requirements. While the 1mm sheet is lighter and well-suited for applications that demand lower weight, like interior paneling or lightweight structures, the 2mm option provides extra resilience—ideal for structural components facing greater pressures.

When exposed to impact or stress, the 2mm thickness ensures added resistance and strength capacity. Different thicknesses might impact fabrication processes as well; thicker sheets may require more robust machining processes, while thinner sheets lend themselves to easier handling.

Standards and Implementation

Adhering to industry standards during manufacture and implementation is essential. The ASTM B209 standard outlines the specifications for aluminum and aluminum alloy rolled or cold-finished sheet and plate. It ensures quality and uniform composition across the board, giving manufacturers and consumers the peace of mind that they are investing in reliable materials.

Whether you're in construction, automotive manufacturing, or maritime engineering, the outlined parameters will guide you in leveraging the advantages this specific alloy brings.

Chemical Composition

Knowing the chemical breakdown gives a clearer picture of how these physical properties are achieved. For the 5154 alloy, it's primarily composed of aluminum with the following percentages:

- Aluminum (Al): 90.4% - 95.0%

- Magnesium (Mg): 4.0% - 5.5%

- Manganese (Mn): 0.5% - 1.1%

- Silicon (Si): 0.0% - 0.25%

- Others (FE, Cu, Zn, etc.): 0.0% - 0.15%

https://www.aluminumplate.net/a/1mm-2mm-thick-aluminium-sheet-alloy-5154-a-h28.html