2021 Professional High Durability Thermal CTP Plate

The 2021 Professional High Durability Thermal Computer-to-Plate (CTP) Plate represents the pinnacle of modern anodized aluminum printing plates, engineered specifically for high-demand commercial printing environments requiring long run lengths, sharp image quality, and reliable press performance. This product is formulated using premium-grade aluminum alloy and advanced surface coating technology, ensuring improved sensitivity and exceptional durability.

Thermal CTP plates operate by using heat to create the image directly on the plate’s surface, eliminating the need for chemical processing. The 2021 Professional High Durability Thermal CTP Plate has been developed with an emphasis on thermal sensitivity and chemical resistance, tailored for high-speed digital exposure workflows.

| Feature | Description |

|---|---|

| Plate type | Thermal Computer-to-Plate (CTP) |

| Base material | Chemically etched aluminum-magnesium alloy C59500 (AlMg3) |

| Plate thickness | 0.30 mm (standard), 0.40 mm (optional) |

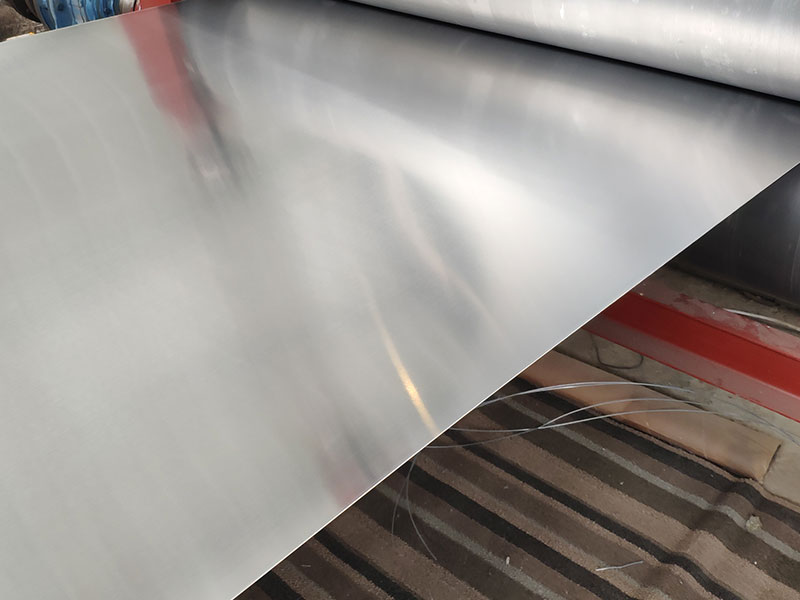

| Surface finish | Ultra-smooth, anodized with hydrophilic graining |

| Imaging technology | Thermal laser (830 nm – 850 nm wavelength) |

| Run length | Up to 500,000 impressions (depending on press and ink system) |

| Sensitivity | ≥110 mJ/cm² (thermal laser platesetter energy level) |

Alloy Composition and Mechanical Properties

The base plate is commonly manufactured from the A59500 series aluminum alloys, selected for their ideal balance between hardness, corrosion resistance, and flexibility suitable for thermal CTP applications.

| Element | Composition (%) | Role |

|---|---|---|

| Aluminum (Al) | 96.5 – 99.0 | Core substrate, lightweight, strong |

| Magnesium (Mg) | 1.8 – 3.5 | Increase strength and improve corrosion resistance |

| Manganese (Mn) | ≤ 0.5 | Grain structure refinement |

| Iron (Fe) | ≤ 0.4 | Impurity consideration |

Mechanical Properties

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | ≥ 175 MPa | ASTM B557 |

| Yield Strength | ≥ 145 MPa | ASTM B557 |

| Elongation | ≥ 12% | ASTM B557 |

| Hardness (HV) | 40 – 55 | ASTM E92 |

Tempering Conditions

Temper designation influences hardness and elasticity of the plate substrate, thus affecting plate bending and mounting flexibility:

| Alloy Temper | Mechanical Behavior | Typical Use in CTP Plates |

|---|---|---|

| H14 – Half Hard | Moderate hardness, good stiffness | Standard commercial run plates |

| H16 – Hardened | Higher hardness, improve dimensional stability | High durataion press cycles |

| O – Annealed | Soft, good malleability | Rare; used mainly in prototype or special orders |

The 0.30 mm plate thickness available in H16 temper offers the perfect compromise by delivering wear resistance while allowing ease of processing and mounting on various plate cylinders.

Surface Treatment and Coating

Our plates undergo a series of treatments to optimize the surface for thermal imaging:

- Chemical Etching: Produces Arab grapegrained anodized surface to increase ink receptivity and reduce dot gain.

- Anodization: Electrochemical process depositing a stable oxide film of 8 – 10 microns thickness for mechanical wear resistance and corrosion prevention.

- Polymer Thermosensitive Layer: Hydrophilic coating embedded on the anodic layer, sensitive to specific thermal laser wavelengths ensuring clean image developability without chemical processing.

- Hydrophilicity Treatment: Critical for non-image areas, providing excellent water-retaining ability necessary for stable printing ink-water balance.

Implementation Standards and Compliance

| Standard | Compliance Details |

|---|---|

| ISO 12647-8:2016 | Offset CTP Plate specifications—ensuring consistent image quality |

| ASTM F1817-11 | Standard Specifications for Non-Processing Negative Acting CTP Plates |

| RoHS and REACH Compliance | Environmentally safe, free from hazardous substances |

All plates pass rigorous quality inspection for surface flatness, sensitivity uniformity, and chemical resistance, strongly recommended for use on high-speed offset printing presses with ink flow automation.

Plate Handling and Shelf Life

- Plates must be stored in a cool, dry environment (temperature 20 ± 5°C, relative humidity 50 ± 5%).

- Recommended shelf life: 12 months from production date when kept in original sealed packaging.

- Safe handling to avoid contamination by grease or moisture; gloves should be worn during assembly and transportation.

https://www.aluminumplate.net/a/2021-professional-high-durability-thermal-ctp-plate.html