2mm aluminum plate

The Sublime Strength of a 2mm Aluminum Plate: An Exploration Beyond the Ordinary

When one thinks of aluminum, the mind often drifts to expansive sheets used in constructions or intricate machinery. However, at the intersection of strength, versatility, and practicality lies the humble yet powerful 2mm aluminum plate. Often overlooked, this thin but robust piece provides remarkable advantages across various applications, exceeding the expectations of engineers, DIY enthusiasts, and artists alike.

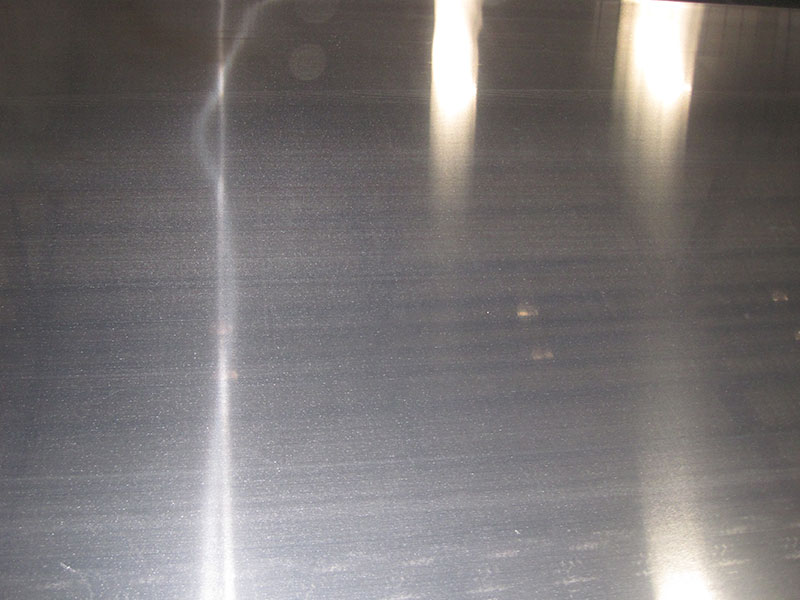

Working with 2mm aluminum plate presents a unique set of challenges compared to thicker gauges. Its thinness makes it incredibly susceptible to warping during processes like welding or even simply heating for surface treatments. We've seen numerous instances where improper clamping or uneven heat distribution leads to significant distortion, requiring rework or even scrapping the piece. Furthermore, the material's flexibility can be both a benefit and a drawback. While it allows for easier forming and bending, achieving precise, repeatable bends requires meticulous control of tooling and pressure. A slight miscalculation can lead to cracking or permanent deformation. This necessitates careful attention to detail throughout the entire production cycle, from cutting and handling to finishing.

Our experience also highlights the importance of proper material selection for specific applications. While the 2mm gauge offers a good balance between weight and strength, its thinner profile makes it less resistant to dents and scratches. Therefore, choosing the correct alloy, like 5052 for its superior corrosion resistance, is crucial. We've learned that detailed quality control checks are paramount, especially at the cutting and handling stages, to prevent surface imperfections. Even minor scratches can negatively impact the final product's appearance and potentially compromise its structural integrity in specific use-cases. Therefore, a comprehensive of the plate's limitations and its intended application is to efficient and effective manufacturing.

Aluminum Alloy Properties

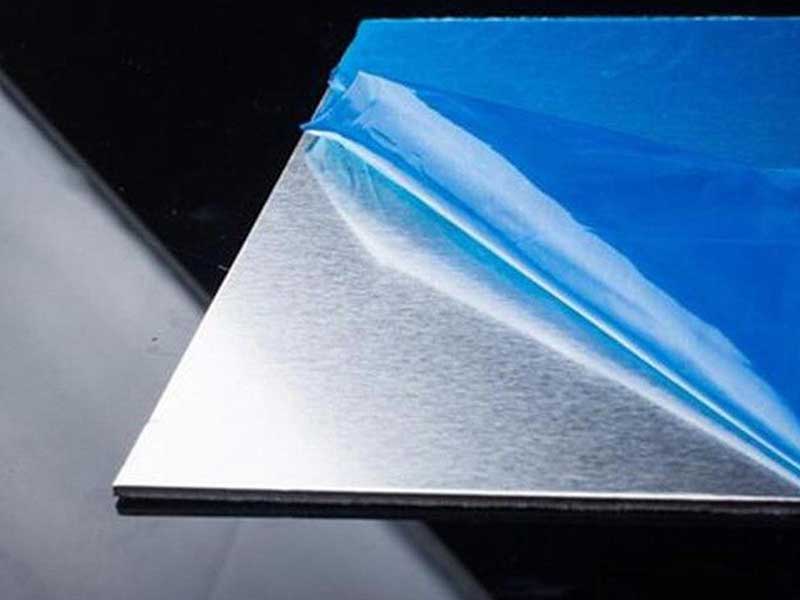

The aluminum alloy used in 2mm plates primarily influences their characteristics. Commonly, 5052 or 6061 alloys are found in such plates due to their corrosion resistance, weldability, and malleability. For instance, while 5052 has excellent formability, making it suitable for projects needing bending and manipulation, 6061 boasts exceptional mechanical properties, often preferred for structural applications. Alongside these alloys, new innovations in aluminum production enhance performance without compromising sustainability, making aluminum a top choice in eco-conscious industries.

Practicality Meets Innovation

In industrial settings, a 2mm aluminum plate can function beyond its structural duties—it is crucial in lightweight applications. From within marine constructions to aerospace components, the value of a lightweight material cannot be overstated—for instance, in the automotive industry where fuel efficiency is paramount. Integrating 2mm plates into car chassis designs leads to significant reductions in weight, enhancing overall performance without sacrificing safety.

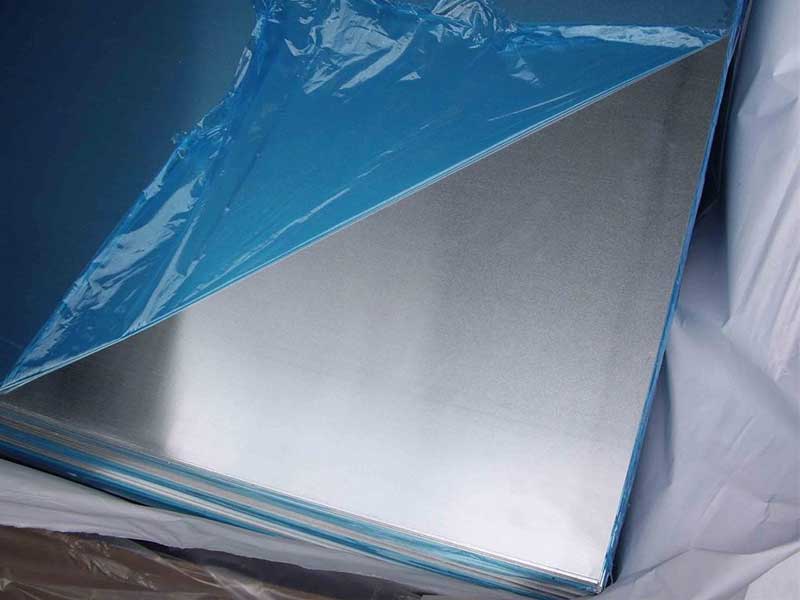

Moreover, the aesthetic potential of a 2mm aluminum plate should not be dismissed. Artists and designers increasingly turn to aluminum for its modern hue and texture. Whether cut into intricate shapes for home decor or utilized as a robust surface for kitchen installations, these plates lend an industrial chic to both spaces and products. Techniques such as anodizing can further enhance their visual appeal while delivering an extra layer of protection.

The Artist’s Medium

Intricately detailed designs, mechanical structures, and sculptures are some of the creative endeavors emerging from the relative malleability of these 2mm plates. Each cut or bend opens doors to artistic expression that celebrates industrial materials. For an artist, the challenge lies in bringing emotion and narrative to life through steel and aluminum. The precision-cut edges of a 2mm aluminum plate serve not just functional purposes but also contribute profoundly to an artist's vision.

With advancements in CNC machining and laser-cutting technologies, shaping these plates into unique forms has become readily accessible for creators. This shift has led to a new genre of art where the lines between technology and creative expression blur.

Environmental Benefits

In a world where sustainability reigns supreme, persons using 2mm aluminum plates can feel comfortable about their choice’s eco-friendliness. Aluminum is nearly entirely recyclable, maintaining its material properties across multiple cycles without degradation. As industries grapple with environmental impact, opting for an aluminum solution reduces landfill contributions and promotes responsible manufacturing processes.

Interestingly, the same6082 aluminum alloy that lends the desired strength and weight reduction can also reopen discussions on circular economies. In particular, aluminum recycling processes require roughly 5% of energy compared to initial production of virgin aluminum. It plays an essential role in modern sustainability efforts—making thoughts of integrated designs with this lightweight alloy both responsible and forward-thinking.