5005 5052 50754 5083 aluminium sheet boats for fishing

Aluminium alloys in the 5xxx series (magnesium as the primary alloying element) are widely used in marine environments due to their excellent strength-to-weight ratio, good corrosion resistance in seawater, and ease of fabrication. For fishing boats — where durability, corrosion resistance, low maintenance and light weight are critical — alloys such as 5005, 5052, 5075A and 5083 are commonly specified for hull plating, superstructures, decks, and fittings.

features and benefits

- Excellent corrosion resistance in marine environments (especially 5083 and 5052).

- High strength-to-weight ratio relative to steel — reduces displacement and fuel consumption.

- Good formability for complex hull shapes and internal structures.

- Weldability using common processes (MIG/GMAW, TIG/GTAW, brazing in some cases).

- Low magnetic signature (beneficial for certain electronics and navigation equipment).

- Recyclable, environmentally friendly material lifecycle.

- Low maintenance compared with steel (no rust, lower need for coatings in some cases).

Typical marine applications

- Small to medium-sized fishing hulls and runabouts

- Decks, hatches, and superstructures

- Stringers, frames, and internal structural members

- Fuel tanks (in specific alloy/temper conditions and with recommended precautions)

- Davits, railings, cleats, and fittings

- Fish holds and live-well linings (with appropriate anti-corrosion measures)

- 5005: General-purpose decorative and structural alloy; good corrosion resistance and excellent anodizing capability. Often used in non-structural exterior panels and trim.

- 5052: One of the most widely used marine aluminium alloys — excellent corrosion resistance, good formability and moderate strength. Common in hull plating, decks and superstructure.

- 5075A: Higher strength compared to 5052, intended for marine structural applications where stronger plate is required while maintaining good corrosion resistance.

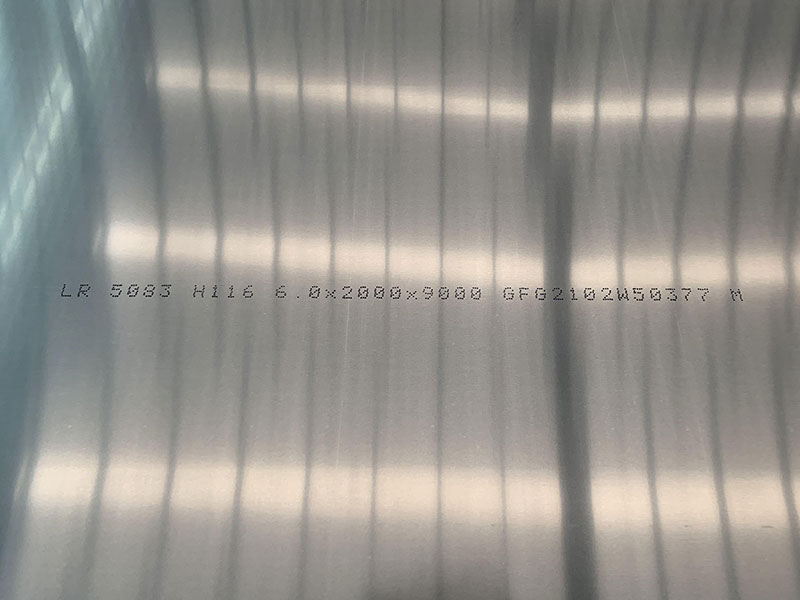

- 5083: High-strength marine-grade alloy with excellent corrosion resistance — commonly used for hulls, offshore structures and higher-load structural components.

Technical specifications

Below are typical chemical and mechanical properties for the alloys. Values shown are indicative — consult supplier mill certificates and relevant standards (e.g., ASTM B209, EN 485, ABS/LR/DNV specifications) for guaranteed properties.

Chemical composition (typical, wt%)

| Alloy | Mg | Mn | Cr | Fe | Si | Cu | Zn | Al (balance) |

|---|---|---|---|---|---|---|---|---|

| 5005 | 0.5 — 1.1 | 0.2 — 0.7 | ≤0.1 | ≤0.7 | ≤0.25 | ≤0.1 | ≤0.25 | remainder |

| 5052 | 2.2 — 2.8 | 0.1 — 0.4 | ≤0.15 | ≤0.4 | ≤0.25 | ≤0.1 | ≤0.25 | remainder |

| 5075A | 3.0 — 3.5 | 0.3 — 1.0 | 0.05 — 0.25 | ≤0.5 | ≤0.25 | ≤0.1 | ≤0.25 | remainder |

| 5083 | 4.0 — 4.9 | 0.4 — 1.0 | 0.05 — 0.25 | ≤0.5 | ≤0.4 | ≤0.1 | ≤0.25 | remainder |

Notes:

- Exact ranges depend on specification and mill. “5075A” composition may vary by producer and specification — sometimes also listed as 5075.

- Balanced aluminium concentration is the remainder after listed elements.

Mechanical properties (typical annealed / strain-hardened tempers)

| Alloy / Temper | Tensile strength (MPa) | Yield strength (0.2% proof, MPa) | Elongation (%) |

|---|---|---|---|

| 5005-H32 (strain-hardened & stabilized) | 160 — 210 | 110 — 150 | 6 — 12 |

| 5052-H32 | 200 — 260 | 120 — 200 | 8 — 12 |

| 5075A-H111 / H32 | 270 — 320 | 140 — 230 | 6 — 10 |

| 5083-H111 / H116 | 300 — 360 | 150 — 290 | 8 — 18 |

Notes:

- H111, H116, H32 denote production tempers/strain hardening and any stabilization; mechanical properties will vary accordingly.

- Higher-strength tempers increase yield and tensile strength but may reduce elongation/formability.

Physical properties

- Density: ≈ 2.66 — 2.70 g/cm³ (all alloys similar)

- Thermal conductivity: ~138 — 160 W/m·K (varies with alloy)

- Coefficient of thermal expansion: ~23.0 × 10⁻⁶ /°C

- Electrical conductivity: alloy dependent, generally lower than pure aluminium

Fabrication, welding and corrosion behavior

Fabrication:

- All four alloys offer good cold formability, though formability decreases as Mg content (and strength) increases. 5005 and 5052 are easiest to form; 5075A and 5083 require more force and controlled forming.

- Bending and rolling practices should account for springback consistent with yield strength and thickness.

Welding:

- All are weldable by MIG (GMAW), TIG (GTAW), and automatic processes. Use matching or appropriate filler alloys (commonly ER5356 or ER5087 for 5xxx series).

- Pre-weld cleaning, proper joint fit-up, and control of heat input reduce porosity and hot cracking risk.

- 5083 has excellent weld strength retention; 5052 also welds well. 5075A can be welded but consult supplier for recommended filler and procedure.

Corrosion:

- 5xxx series alloys exhibit good resistance to seawater corrosion; resistance typically improves with higher magnesium content up to a point.

- 5083 and 5052 are especially well-suited for seawater exposure. 5005 is adequate for less demanding marine exterior use.

- Beware of galvanic corrosion when joining to dissimilar metals (steel, copper, bronze). Use insulating materials, appropriate fasteners (stainless steel or aluminium fasteners), and protective coatings where required.

- Stress corrosion cracking (SCC) is a concern in high-Mg alloys under certain conditions (particularly in the 5xxx family when Mg > ~3.5% and under high tensile stress). 5083 in H116/H321 tempers has improved resistance; proper design to avoid prolonged tensile stresses and use of correct tempers reduces risk.

Design and performance considerations for fishing boats

- Weight savings: replacing steel with 5xxx aluminium can reduce hull weight by up to 70% depending on thickness and design; this improves payload, speed, and fuel efficiency.

- Thickness selection: choose thickness based on hull size, expected loads, and regulatory standards. Small boats (4–8 m) commonly use 2–4 mm plates; larger planing hulls 4–8 mm or more; commercial vessels and offshore craft may use 8–12 mm or higher.

- Impact & abrasion: consider local reinforcements (keel strips, rubbing strakes) for beaching or frequent impact. Harder alloys / thicker plates perform better against abrasion.

- Acoustic considerations: aluminium hulls transmit more noise and vibration than GRP; use sound insulation and engine mounts to reduce noise for fish-finding and crew comfort.

- Repairability: aluminium is relatively easy to repair by welding; keep spare plates/patches and use qualified welders for field repairs.

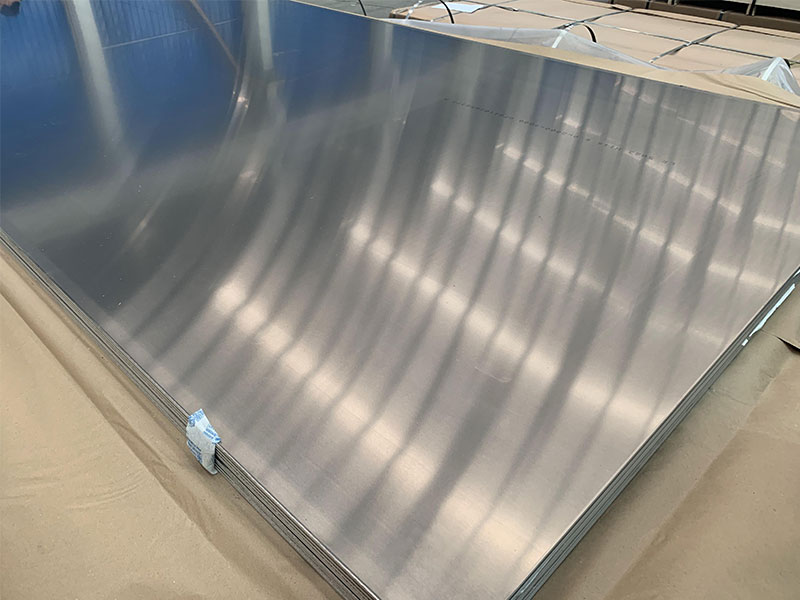

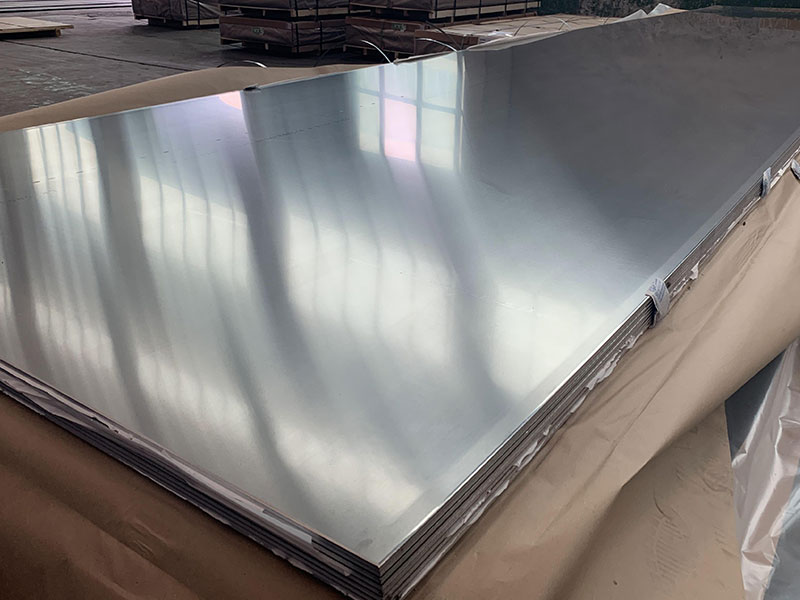

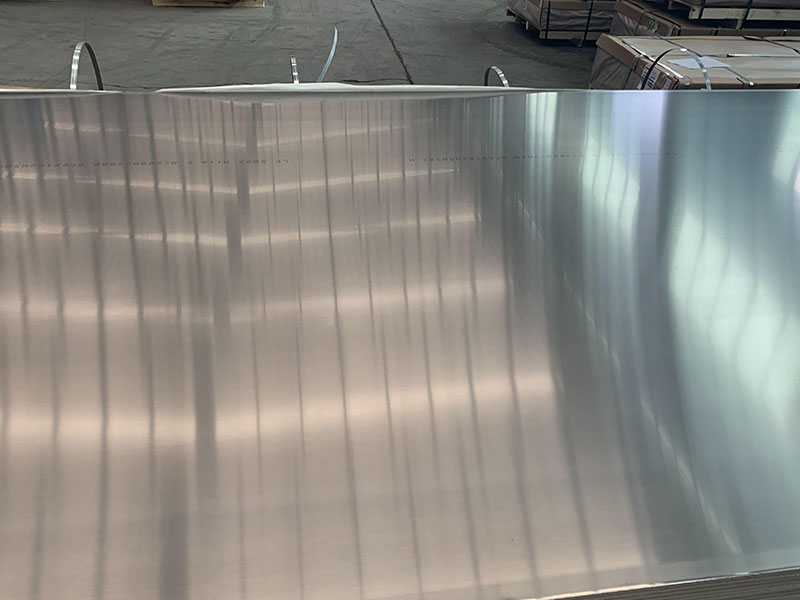

Typical product forms and tolerances

- Sheet/plate thickness range: commonly 1.0 mm — 200 mm in mill production; typical boatbuilding plates 2 mm — 12 mm.

- Widths: up to 2,000 mm or wider on special mills.

- Lengths: cut-to-length per order; common lengths 2—12 m depending on mill.

- Surface finish: mill finish, anodized (5005 is excellent for anodizing), pre-painted (PVDF/PE), or chemical conversion coatings for additional corrosion resistance.

- Standards: ASTM B209, EN 485, ISO 6361 for general sheet/plate specifications; classification societies for structural components on classed vessels.

Quality, certification and testing

- Mill test certificates (MTC) should accompany orders showing chemical composition and mechanical test results.

- Common tests: tensile test, hardness, chemical analysis, ultrasonic or radiographic testing for thicker plates (structural/critical areas), and non-destructive testing for welds (PT/MT/UT).

- Classification society approvals (ABS, DNV, Lloyd’s Register) may be required for commercial fishing vessels and offshore craft; consult the society for acceptable alloys, tempers and thicknesses.

Selection guide — which alloy to choose?

- For non-structural exterior panels, decorative trim and anodizing: 5005 is cost-effective and anodizes well.

- For general-purpose hulls, decks and superstructure where good corrosion resistance, formability and moderate strength are needed: 5052 is a common choice.

- For applications requiring higher strength with still good corrosion resistance (stiff hulls, thicker plates, or where weight savings at higher strength matter): consider 5075A.

- For heavy-duty hull plating, offshore or commercial fishing boats where maximum seawater corrosion resistance and higher strength are required: 5083 (H116/H111 tempers) is preferred.

- Always consider thickness, welding method, and service environment (salinity, temperature, mechanical stresses) when selecting.

Example use cases

- Small recreational aluminum skiff: 5052-H32, 2–4 mm plate for hull and deck — lightweight, easy to form, low maintenance.

- Larger 7–9 m workboat used for coastal fishing: 5083-H116, 4–6 mm hull plating with 5052 for interior superstructure — combines high hull strength with good formability for non-critical parts.

- Fish-processing tender exposed to heavy use and saltwater: 5083 for hull and structural members, with anodized 5005 for visible trim and panels.

- Commercial aluminum trawler components requiring higher yield strength: 5075A for selected structural members with matched filler for welding.

https://www.aluminumplate.net/a/5005-5052-50754-5083-aluminium-sheet-boats-for-fishing.html