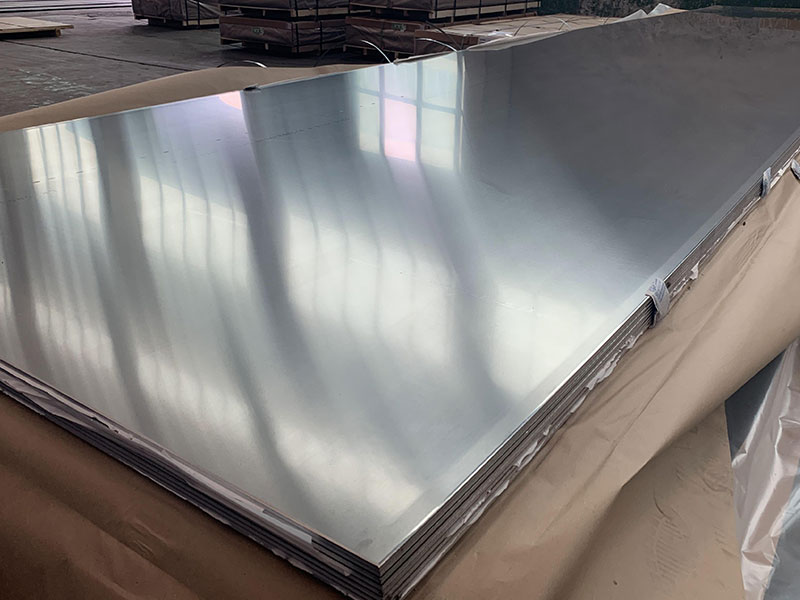

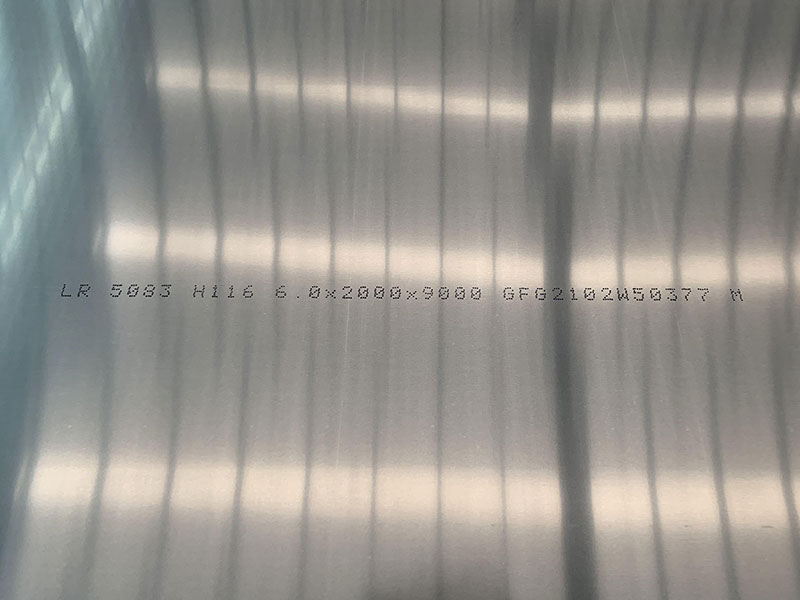

7.5 mm marine grade 5083 h16 h22 aluminium sheet plate

the Exceptional Qualities of 7.5 mm Marine Grade 5083 H16 H22 Aluminium Sheet Plate

Aluminium alloys are widely respected for their robust characteristics, especially in demanding environments like marine applications. Among these alloys, 5083 H16 H22 stands out for its splendid combination of performance, aesthetics, and longevity.

Working with 7.5mm 5083-H16/H22 marine-grade aluminum sheet plate presents a unique set of considerations. The thickness itself makes handling more challenging than thinner gauges; specialized equipment like overhead cranes or powered lift tables are frequently necessary to maneuver large sheets safely. Furthermore, the H16 and H22 tempers represent a trade-off between formability and strength. H16 offers better formability, ideal for complex curved components like boat hulls or superstructures, while H22 provides superior strength but is more difficult to bend or shape without specialized tooling and potentially more pre-heating. We often find that choosing between these tempers depends heavily on the specific application; a complex hull section might benefit from H16, while a structural support beam would prefer the higher strength of H22. Careful consideration must also be given to edge preparation and weldability, as thicker sections require more attention to avoid cracking or distortion during welding processes.

Beyond the material properties, experience shows that surface preparation is paramount for optimal performance and longevity. Marine environments are notoriously harsh, with salt spray, UV exposure, and potential for galvanic corrosion. Therefore, we meticulously inspect incoming sheets for surface imperfections and ensure thorough cleaning and pre-treatment before any fabrication or coating. The choice of coating – whether powder coating, anodizing, or a specialized marine paint system – is also crucial in extending the lifespan of the final

The Heart of Marine Applications: Marine Grade 5083

At first glance, the dimensions of a 7.5 mm sheet plate may seem modest compared to thicker decks or structural frameworks found in marine vessels. However, within this millimeter count lies the heart of marine application demands. The nomenclature 5083 signifies significant magnesium content within the alloy, which contributes both to corrosion resistance and to formability. The H16 and H22 temper designations denote specific heat-treatment strengthening, ensuring that this alloy plate retains its integrity under stress while exhibiting lesser deformation when bent or subjected to load.

Why Choose 7.5 mm?

Many may wonder, “Why is a 7.5 mm thickness a preferable choice in maritime settings?” Here’s where we shift our perspective to look at the strategic advantages. The choice of dimensions in a marine-grade aluminium plate directly affects the vessel's overall weight and buoyancy. A 7.5 mm thickness strikes a refined balance—being sturdy enough to contribute to a construction’s robustness, yet lightweight enough to preserve the vessel’s sea-bound agility. Lighter materials translate into fuel efficiency and greater speed, factors in the competitiveness of modern marine design and technology.

Resistance to Nature’s Forces

Marine environments are notorious for their unforgiving conditions—saltwater, humidity, and varying temperatures can wreak havoc on structural integrity. Choosing the 5083 alloy grade ensures shortsightedness is avoided. This aluminium plate boasts exceptional resistance to pitting and stress corrosion, delightful attributes for shipbuilders and manufacturers crafting components that must withstand such relentless natural forces. Unlike rigid materials, 5083 H16 H22 flexes remarkably well under pressure without succumbing to premature failure. This characteristic is critical for components like hulls, superstructures, and other areas highly exposed to the harsh marine atmosphere.

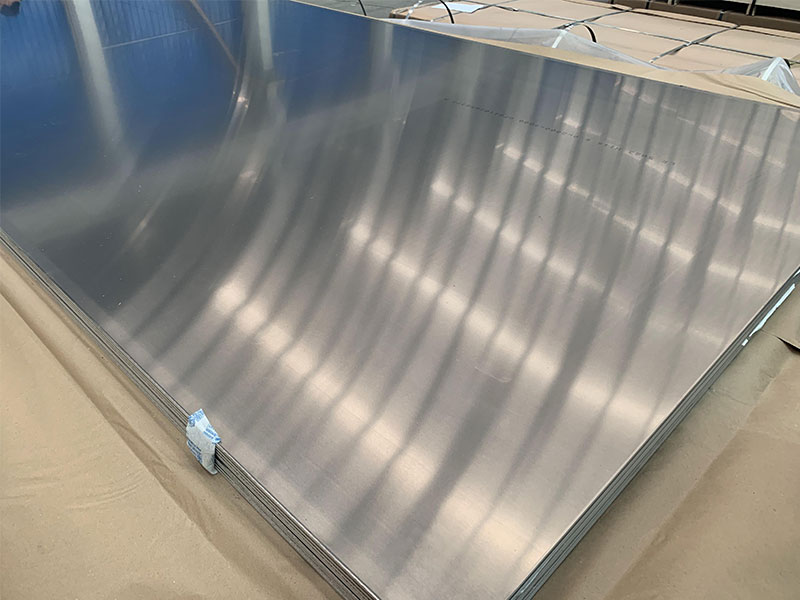

Fabricability and Finish

An unexplored dimension when considering marine-grade aluminium is the simplicity of fabricability that 5083 provides, particularly in the 7.5 mm dimension. Its ability to be readily welded, cut, and shaped translates into greater versatility during manufacturing operations. This ease means less tooling stress for engineers and manufacturers, allowing them the creative freedom necessary to accomplish innovative designs securely prone to modernization requirements.

Moreover, a lightweight and smoothly finished plate with respectable malleability gives rise to an aesthetic edge handed to boat designers and builders. When cleanliness directs attention to the overall theme—especially for luxury yachts—looking impeccable while being devilishly durable becomes non-negotiable.

Real-Life Applications

From megayachts to fishing boats and coast guard vessels, the applications of 5083 H16 H22 aluminium sheets are extensive. Their thinness enables complex modular constructions without introducing counterproductive weight disparities. Significantly, it offers boat builders the ability to allocate weight efficiency into sophisticated design while extending capabilities for other equipment mounting areas—resulting in broader utility range over extended lifespans.

Now, when contemplating the utility, think also of various components—balconies, cargo tanks, and observations studios—for they unify buoyancy and superb visual allure, unlike heavier alternatives that lead to limitations in operational prowess.

https://www.aluminumplate.net/a/75-mm-marine-grade-5083-h16-h22-aluminium-sheet-plate.html