Aluminium Sheet For Making The Sign

Aluminium sheet is one of the most reliable and widely specified substrates for indoor and outdoor signage. It combines low weight with excellent corrosion resistance, stable flatness, and clean surface finish-making it ideal for printed, painted, laminated, or digitally imaged signs. Whether you are producing storefront logos, traffic guidance plates, safety labels, architectural wayfinding, or industrial nameplates, an aluminium sign sheet delivers long service life with consistent appearance.

Why Aluminium Sheet Works So Well for Signs

Sign-making needs a material that is easy to fabricate, stays flat, resists weathering, and accepts graphics without unpredictable adhesion issues. Aluminium sheet meets these needs by offering:

- Excellent corrosion resistance for outdoor exposure, especially in 3xxx and 5xxx series alloys

- High strength-to-weight ratio, reducing installation load and making handling easier

- Good formability for bending, folding, roll forming, and light stamping

- Smooth, consistent surface that supports printing, vinyl, and coatings

- Recyclability and strong sustainability profile compared with many alternatives

Common Applications

Aluminium sign sheet is used across commercial, municipal, and industrial projects:

- Building façade signs, channel letter backing plates, and illuminated box panels

- Wayfinding systems for malls, hospitals, campuses, airports, and metro stations

- Traffic and road signage blanks (often paired with reflective film)

- Safety and warning plates in factories, warehouses, and chemical plants

- Machine labels, serial plates, and barcode/QR plates (often anodized)

- Directional plates, parking signs, and outdoor information boards

- Decorative signage with brushed, anodized, or painted finishes

Recommended Alloys and Tempers for Sign-Making

Different sign types need different performance balances. The table below summarizes widely used options.

| Alloy | Typical Temper | Best For | Strength Level | Formability | Corrosion Resistance | Notes |

|---|---|---|---|---|---|---|

| 1050 / 1060 | O, H14, H18 | General indoor signs, printing panels | Low | Excellent | Good | Very clean surface; easy to cut and bend |

| 1100 | O, H14 | Printing, anodizing, nameplates | Low | Excellent | Good | Classic "commercially pure" choice |

| 3003 | H14, H24 | Outdoor signs, general-purpose blanks | Medium | Very good | Very good | Most common sign alloy for cost-performance |

| 3004 | H34 | Panels needing higher strength | Medium-high | Good | Very good | Stronger than 3003, good for larger panels |

| 5052 | H32, H34 | Coastal/industrial outdoor signs | Medium-high | Good | Excellent | Superior salt-spray resistance; slightly higher cost |

| 5083 | H111 | Heavy-duty marine/industrial panels | High | Fair-good | Excellent | For demanding environments; not typical for small signage |

Chemical Composition (Typical)

Actual chemistry follows ASTM/EN limits and mill certification. The values below are typical ranges used to help customers compare alloy families.

| Alloy | Al (min) | Mn | Mg | Si | Fe | Cu | Others (each) |

|---|---|---|---|---|---|---|---|

| 1050 | 99.50% | ≤0.05% | ≤0.05% | ≤0.25% | ≤0.40% | ≤0.05% | ≤0.03% |

| 1100 | 99.00% | ≤0.05% | - | ≤0.95% (Si+Fe) | - | 0.05–0.20% | ≤0.05% |

| 3003 | rem. | 1.0–1.5% | - | ≤0.60% | ≤0.70% | ≤0.20% | ≤0.05% |

| 5052 | rem. | ≤0.10% | 2.2–2.8% | ≤0.25% | ≤0.40% | ≤0.10% | ≤0.05% |

Note: "rem." indicates aluminium remainder after alloying elements.

Technical Specifications for Aluminium Sign Sheet

The specifications below reflect typical supply ranges for sheet and coil used in sign fabrication, printing, and lamination.

| Item | Typical Range / Option | Notes for Sign Makers |

|---|---|---|

| Thickness | 0.3–6.0 mm | 0.8–3.0 mm is most common for rigid sign panels |

| Width | 1000–2000 mm | Custom slitting available for production lines |

| Length | 2000–6000 mm | Sheet supply for flatbed printing and cutting tables |

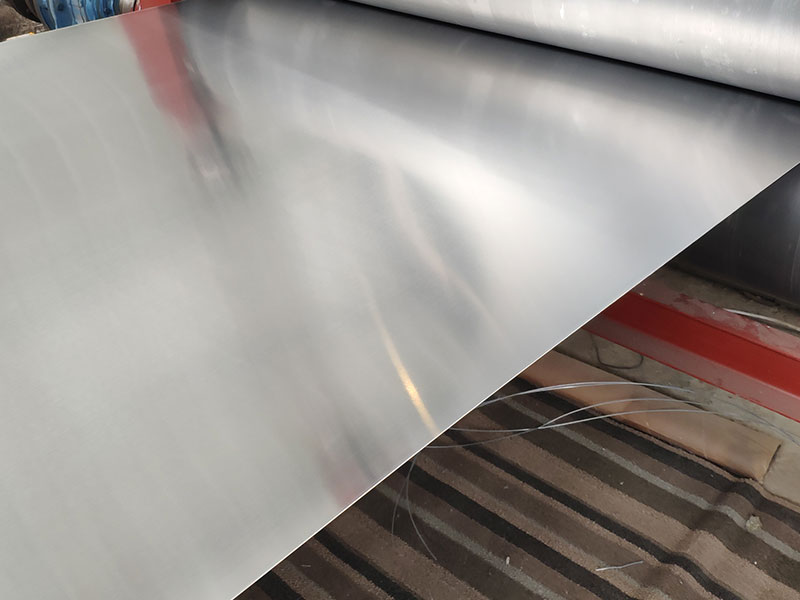

| Form | Sheet / Coil | Coil preferred for roll-form or continuous lamination |

| Temper | O, H14, H24, H32, H34 | Choose softer for deep bends, harder for flatness |

| Surface finish | Mill finish, brushed, bright, matte | Match branding and reflection requirements |

| Coating options | PVDF, PE, polyester, primer | For ACM skins or direct-coated sign panels |

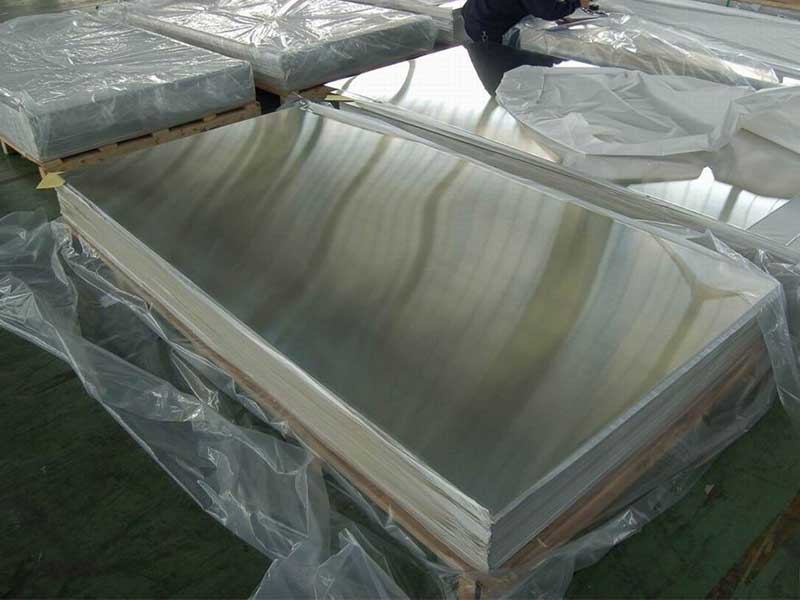

| Protective film | PE film (single/double side) | Protects during routing, printing, and transport |

| Standards | ASTM B209, EN 485 | Confirm per project region/spec |

Mechanical and Physical Properties (Typical)

Properties vary by thickness, temper, and supplier process. The table is a practical guide for choosing alloys for stiffness, wind load, and fabrication.

| Alloy & Temper | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Density (g/cm³) | Notes |

|---|---|---|---|---|---|

| 1100-O | ~35 | ~90 | ~30 | 2.71 | Very formable; best for embossed or curved sign parts |

| 3003-H14 | ~115 | ~145 | ~8 | 2.73 | Balanced choice for most outdoor printed signs |

| 5052-H32 | ~160 | ~215 | ~12 | 2.68 | Strong and corrosion resistant; good for coastal signage |

Surface Treatments and Print/Coating Compatibility

A sign sheet succeeds or fails at the surface. For consistent graphic adhesion and weather durability, aluminium sign sheet is typically specified with one of these surface routes:

| Surface Route | Visual Result | Adhesion Behavior | Weather Durability | Common Uses |

|---|---|---|---|---|

| Mill finish (degreased) | Natural metallic, semi-matte | Good with proper primer/ink system | Good | General panels, painted signs |

| Brushed (hairline) | Premium texture | Good; needs clean handling | Good | Branding plates, architectural signs |

| Anodized | Hard, decorative | Excellent for engraving/laser | Excellent | Nameplates, QR plates, high-end signage |

| Pre-painted (coil coated) | Uniform color | Excellent with controlled system | Excellent (PVDF best) | Outdoor brand panels, long-life façades |

| Primed for digital print | Optimized surface energy | High consistency | Good–excellent | UV printing, screen printing workflows |

For outdoor service, coating selection matters. PVDF is typically favored for long-term color retention, while PE/polyester systems can be a cost-effective choice for shorter cycles or sheltered environments.

Fabrication Performance in the Workshop

Aluminium sheet supports fast, clean production methods common in sign shops and industrial fabricators:

- Cutting: shear, CNC routing, laser (with correct parameters), waterjet

- Forming: press brake bends, roll forming, edge returns, light stamping

- Joining: riveting, bolting, adhesive bonding; welding is possible for some designs

- Finishing: powder coating, wet paint, anodizing, brushing, lamination

Where tight bend radii or deep folds are required, softer tempers such as O or H24 reduce cracking risk. When panel flatness and stiffness are critical for large-format signs, H14/H32 tempers are commonly chosen.

How to Choose the Right Sheet for Your Sign

A good selection is usually driven by the environment, size, and finishing method:

| Scenario | Recommended Alloy/Temper | Typical Thickness | Suggested Surface |

|---|---|---|---|

| Indoor branding, short-term promotions | 1050/1100 H14 | 0.5–1.5 mm | Mill/primed for print |

| Standard outdoor shop signage | 3003 H14/H24 | 1.0–3.0 mm | Primed / pre-painted |

| Coastal roads, chemical plants, high humidity | 5052 H32 | 1.5–4.0 mm | Pre-painted PVDF or anodized |

| Engraved or laser-etched durable plates | 1100/3003 | 0.5–2.0 mm | Anodized |

| Large panels needing better rigidity | 3004 H34 / 5052 H32 | 2.0–6.0 mm | Pre-painted or powder coat |

Quality Points Customers Often Specify

For sign performance and appearance, purchasers often request:

| Quality Item | What It Controls | Typical Request |

|---|---|---|

| Flatness | Panel wave, print distortion | Tighter flatness for UV/flatbed printing |

| Surface cleanliness | Ink/film adhesion | Degreased, low residue |

| Color consistency (coated sheet) | Brand uniformity | Delta E control per batch |

| Protective film | Handling marks | Easy-peel, no glue residue |

| Edge condition | Safety and fit | Deburred edges for sheet supply |

Aluminium Sheet For Making The Sign is a lightweight, corrosion-resistant, and fabrication-friendly material widely used for indoor and outdoor signage. Common alloys like 3003-H14 provide an excellent balance of strength, flatness, and cost, while 5052-H32 is preferred for harsh coastal or industrial environments. Available in a broad range of thicknesses, widths, and surface finishes-including mill finish, brushed, anodized, and pre-painted-aluminium sign sheet supports printing, coating, lamination, and long-term weather exposure with reliable performance and clean aesthetics.

https://www.aluminumplate.net/a/aluminium-sheet-for-making-the-sign.html