1050 1100 H24 Sublimation Aluminum Sheet

Aluminum alloys are renowned for their versatility, durability, and wide-ranging applications across numerous industries. Among these, the 1050 and 1100 series is know due to their exceptional purity and excellent workability. When these alloys are stabilized in the H24 temper, their suitability for sublimation printing transforms, opening an innovative frontier for manufacturers and artists alike.

1. The Purity Paradox — More Than Just High Aluminum Content

At first glance, the 1050 and 1100 alloys are predominantly aluminum, with minimum purity levels of 99.5% and 99.6%, respectively. This high purity imparts these sheets with superb reflective qualities, excellent corrosion resistance, and remarkable tensile strength—features typically synonymous with premium decoration substrates. But what truly distinguishes them from other alloys is their almost "invisible" impurity profile, which minimizes interference with imaging quality. This near-perfect base makes 1050 and 1100 sheets ideal for sublimation, where the clarity and vibrancy of transferred images depend heavily on the base's uniformity.

2. The H24 Temper — Striking a Balance Between Flexibility and Strength

The H24 temper status implies strain-hardened and stabilised work hardening, offering a sweet spot of mechanical properties. For sublimation purposes, H24 plates pursue a balanced profile: they retain enough flexibility for fabrication—routinely shaping, bending, and engraving—yet are robust enough to withstand handling and environmental stressors. From a distinctive viewpoint, this unique state of the aluminum sheet also helps optimize heat conduction for sublimation, ensuring even heat distribution during the process. As a result, images are crisp, vibrant, and consistent—crucial for high-end signage and decorative applications.

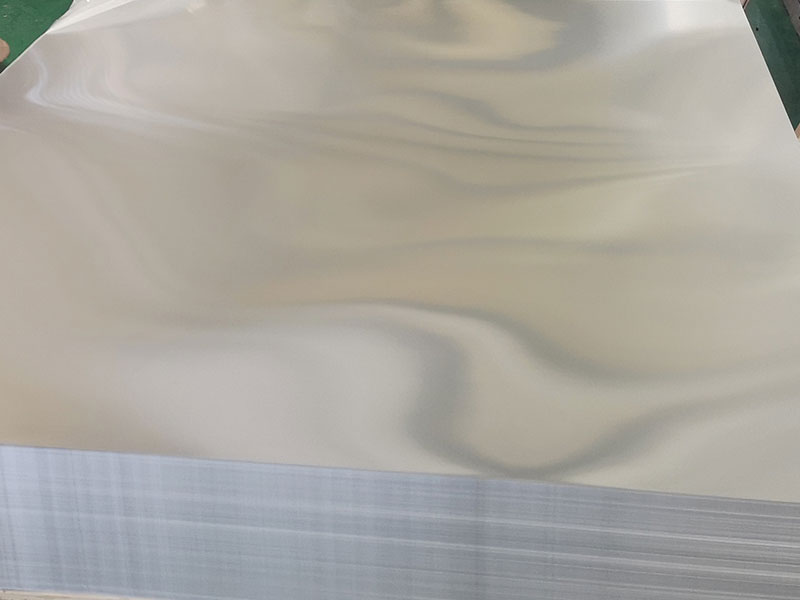

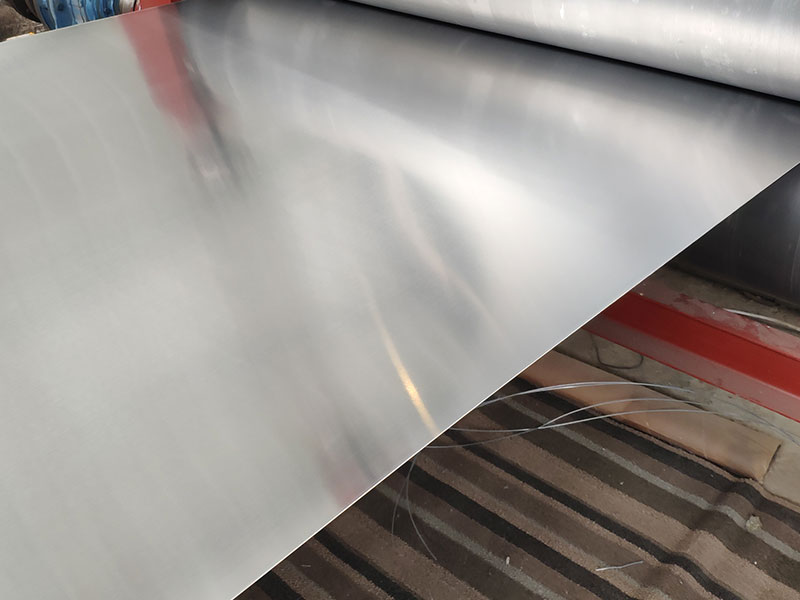

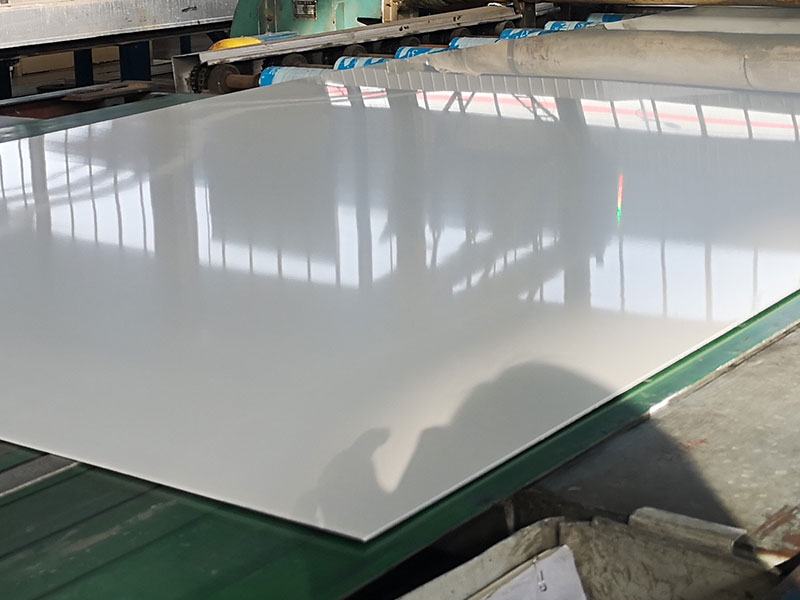

3. Surface Characteristics — The Unsung Hero of Sublimation Success

Perhaps most intriguing from a practical perspective is the surface composition of 1050 and 1100 H24 sheets. Their surface is naturally smooth, with minimal surface treatment requirements before sublimation. This aspect simplifies manufacturing workflows and reduces costs, but also importantly enhances the dx’ printing process. Users note that the uniform, reflective surface means colors pop more vividly, and gradients achieve smoother transitions, adding unmatched aesthetic appeal.

In addition, these sheets can be pre-treated or anodized to boost adhesion during imaging or to achieve specific color effects, expanding creative potentialities while maintaining the materials' inherent strengths.

4. Sustainability and Recyclability — Aligning with Future Industry Demands

From a holistic perspective, choosing 1050 and 1100 H24 sublimation sheets aligns with growing environmental consciousness. Aluminium's recyclability is well established; these pure alloys lend themselves to recycling without loss of properties—making them an eco-friendly choice. Moreover, their long-term durability under various conditions aligns with the sustainability trend, reducing waste and ensuring visual integrity over time. For eco-conscious manufacturers and suppliers, leveraging these sheets isn’t just a choice for performance but an environmentally responsible decision as well.

5. Practical Applications and Innovator Advantages

In practice, the applications of these aluminum sheets extend beyond traditional signage to innovative fields such as:

- Custom Art & Decorative Panels: Their finish and sublimation compatibility make them the preferred choice for creating bespoke, resilient wall art with vivid imagery.

- Promotional Items and Awards: Their lightweight nature paired with their image clarity makes trophies, plaques, and corporate giveaways stand out.

- Architectural Accents: For interior design elements, their aesthetic appeal combined with durability enables visually impactful partitions or feature panels.

What sets owners apart, from a pioneering standpoint, is the ability to merge high-quality sublimation transfers with durable aluminum substrates—fostering products that are both artistic and resilient.

The Takeaway — An Elevated Surface for Artistic Expression and Practical Excellence

Thinking of 1050 and 1100 H24 sublimation sheets through a distinctive lens leads to a fundamental insight: they are not merely substrates but blank canvases waiting to be transformed by innovation, creativity, and precise engineering. High purity, balanced hardness, surface uniformity, and eco-friendly properties combine to provide a uniquely synergistic platform—turning the humble aluminum sheet into a vibrant cultural and commercial canvas.

Whether you're a manufacturer seeking reliable, high-quality sublimation media or an artist pushing the boundaries of visual art, these sheets embody a perfect confluence of form, function, and sustainability. Embrace this perspective, and unlock the potential of aluminum that’s durable enough to last, pure enough to impress, and flexible enough to innovate beyond the conventional.

https://www.aluminumplate.net/a/1050-1100-h24-sublimation-aluminum-sheet.html