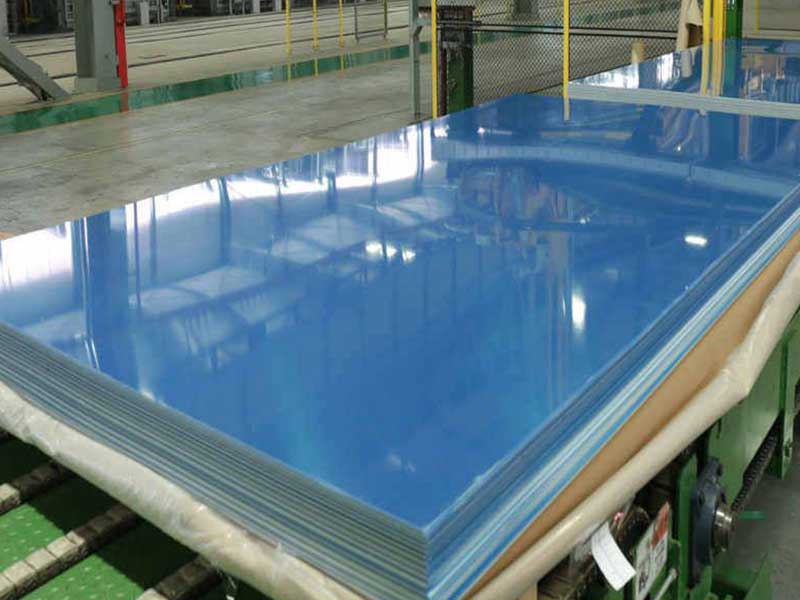

Aluminum sheet 1100 1050 1060 O H14 H24

Aluminum sheets are vital components in many industries due to their excellent properties and applications. Among these, the 1100, 1050, and 1060 grades, with their different temper designations of O, H14, and H24, is know for their unique attributes and versatility.

Features

- High Corrosion Resistance: These aluminum alloys excel in resisting corrosion, making them suitable for outdoor applications and harsh environments.

- Excellent Fabricability: Both O (annealed) and H (strain-hardened) tempers provide high ductility, enabling the material to be easily fabricated, formed, or machined.

- Good Electrical Conductivity: Aluminum is known for its excellent conductivity, which is particularly true for the pure aluminum grades like 1100 and 1050.

- Lightweight: These alloys offer a high strength-to-weight ratio, making them ideal for applications where weight savings are mission-critical.

- Aesthetic Appeal: The clean surface finish can be easily anodized or coated for aesthetic purposes.

Chemical Composition

The following table summarizes the chemical composition of Aluminum sheets 1100, 1050, and 1060.

| Alloy | Al (%) | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) |

|---|---|---|---|---|---|---|---|---|

| 1100 | ≥99.0 | ≤0.25 | ≤0.30 | ≤0.05 | ≤0.05 | – | ≤0.10 | ≤0.05 |

| 1050 | ≥99.5 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | – | ≤0.10 | ≤0.05 |

| 1060 | ≥99.6 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | – | ≤0.10 | ≤0.05 |

Mechanical Properties

The mechanical properties of these aluminum grades provide insight into their performance in various conditions:

| Alloy | Tempers | Yield Strength (psi) | Ultimate Tensile Strength (psi) | Elongation (%) |

|---|---|---|---|---|

| 1100 | O | 7,000 - 9,000 | 12,000 | 30 |

| 1100 | H14 | 15,000 | 22,000 | 4 |

| 1050 | O | 6,000 - 9,000 | 10,000 | 30 |

| 1050 | H14 | 13,000 | 21,000 | 5 |

| 1060 | O | 8,000 - 10,000 | 18,000 | 25 |

| 1060 | H24 | 20,000 | 22,500 | 5 |

Note: Values can vary based on specific production conditions.

Technical Specifications

| Specification | Interpretation |

|---|---|

| Thickness Range | 0.1 mm to 6 mm |

| Width | Up to 2000 mm |

| Length | Up to 6000 mm |

| Surface Finish | Mill finish or custom finishes |

| Standards | ASTM B209, ASTM B321 |

Applications

Aluminum sheets 1100, 1050, and 1060 are employed in a wide variety of applications:

- Household Appliances: Used in manufacturing parts for refrigerators, air conditioners, and cookware due to excellent thermal and electrical conductivity.

- Food & Chemical Transport: Ideal for containers and tanks owing to their low reactivity and efficient cleaning capabilities.

- Architectural Elements: Used for siding, roofing, and decorative applications thanks to aesthetic finish options and durability.

- Heat Exchangers: Their high thermal conductivity benefits automotive and industrial heat exchangers.

- Electronics: Beneficial for heat sinks and housings in various electronic devices due to lightweight and conductive properties.

Benefits

- Cost-effective Variability: These alloys offer competitive pricing while providing a range of properties that suit many needs.

- Sustainability: Aluminum is fully recyclable, supporting environmentally friendly manufacturing processes.

- Long-lasting Performance: Due to corrosion resistance and durability, the long lifespan of these products provides value to investment.

https://www.aluminumplate.net/a/aluminum-sheet-1100-1050-1060-o-h14-h24.html