Color coated mirror finish anodized aluminum sheet 1060

In modern architecture and design, the search for materials that balance aesthetics, functionality, and sustainability is a priority. Enter the Color Coated Mirror Finish Anodized Aluminum Sheet 1060—an innovative blend of beauty and practicality. This specific variant of aluminum marries high strength with unrivaled surface finishing, making it a favorite amongst designers, architects, and manufacturers alike.

Technical Characteristics of 1060 Alloy Aluminum Sheet

One of the selling points of the 1060 aluminum sheet lies in its unique chemical composition and outstanding properties. Below is a chart summarizing its salient features:

| Property | Value |

|---|---|

| Alloy Designation | 1060 |

| Tempering | H14, H16, H18 |

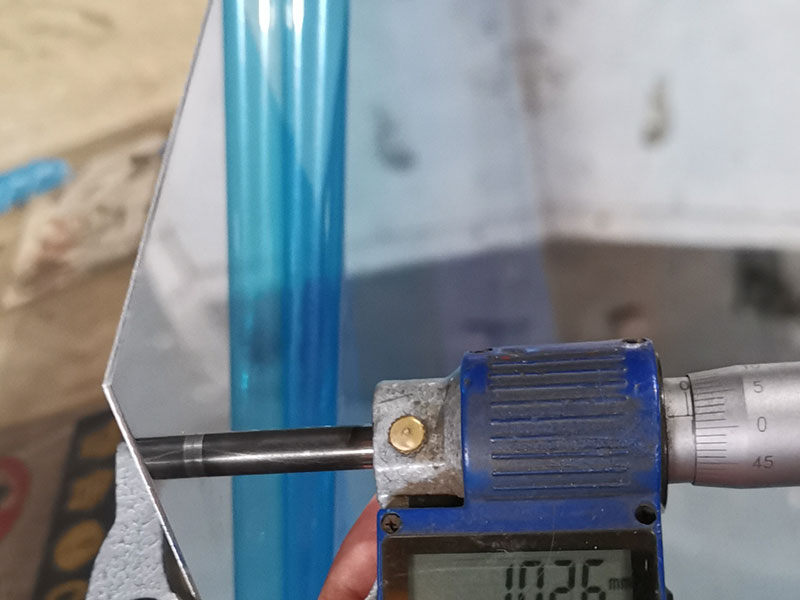

| Thickness (Standard) | 0.2mm - 6.0mm |

| Width | Up to 2600mm |

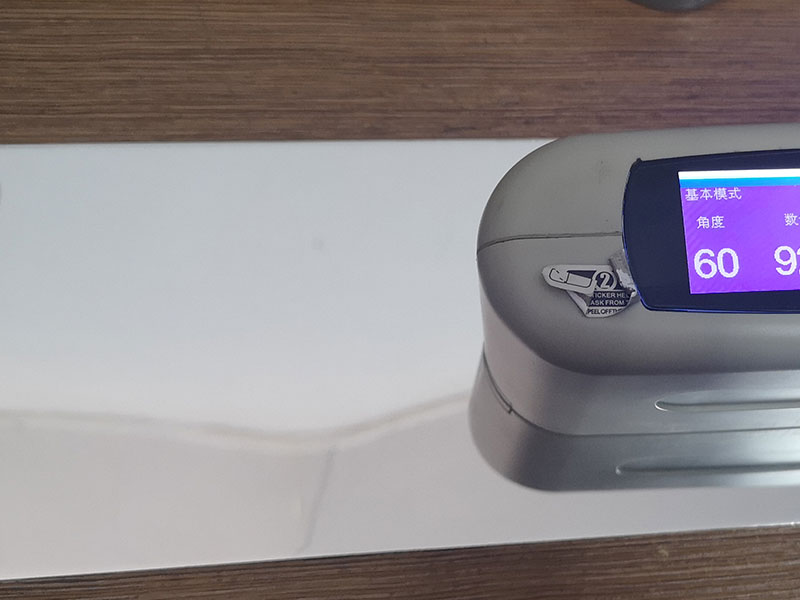

| Surface Finish | Color coated mirror finish, anodized |

| Tensile Strength | 90 MPa (Minimum) |

| Elongation | 11% (Minimum) |

Implementation Standards:The manufacturing adheres to multiple standards that ascertain the quality and safety of 1060 aluminum, including ASTM B211 and ASTM B632, ensuring durability and performance suitable for commercial applications.

In terms of chemical properties, 1060 aluminum has a high resistance to corrosion due to its durable anodized coating layer. This degree of resistance is critical, particularly for applications lessing long-term exposure to the elements, assuaging gaps further maintenance costs.

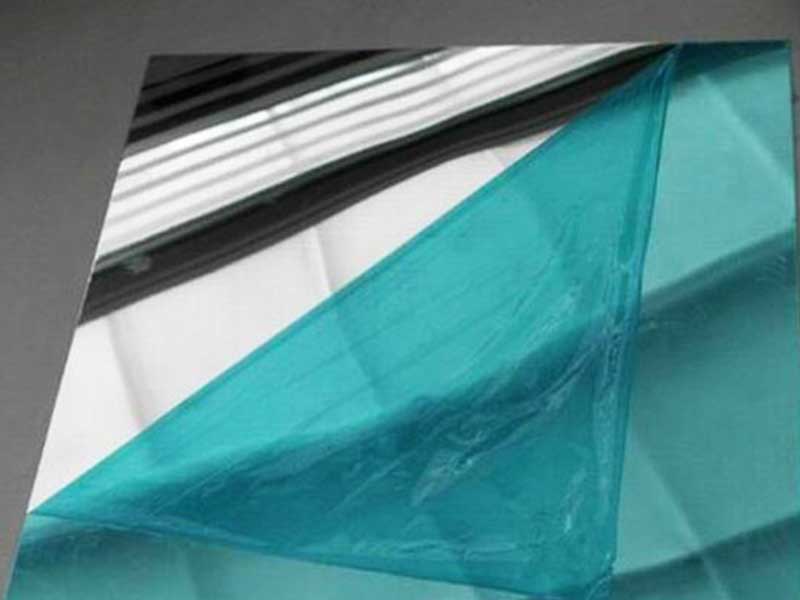

The Mirror Finish Effect: Where Form Meets Function

The mirror-like finish not only enhances aluminum's sleek and modern aesthetic but also serves functional purposes:

Light Reflection: The reflective quality of this aluminum sheet facilitates maximum light projection. This distinctive feature renders it a staple in interior design, where lighting and ambiance play roles.

Visual Attraction: The striking finish has substantially recoverable design metrics, making spaces appear more open, airy, and dynamic which is emblematic in both brackets and high-end consumer products.

Chemical Stability and Safety: Given its anodized state, the 1060 packaging can withstand variances in temperature and impurities, thus offering a product that achieves visual depth while offering durability integral to environments ranging from commercial kitchens to event-related installations.

Packaging Story: Versatile Applications

Thanks to the material properties and the myriad finishes achievable, there are copious applications for Color Coated Mirror Finish Anodized Aluminum Sheet 1060 spanning various sectors:

1. Interior Design:

Insatiable beauty and modernism characterize retail and workspace environments. Architects now leverage anodized aluminum sheets within wall panels, ceiling systems, and furniture components—overlaying charm with functionality and durability.

2. Consumer Goods:

Things like electronic housings, appliance surfaces, and retail displays benefit from its ease of cutting, shaping, and integrating other materials. Products demand high visual appeal while increasing usability—a perfect blend matched by fostering identification through modern design aesthetics.

3. Advertising:

Reflective aluminum sheets create bold visuals for billboards, kiosks, and signage, turning passive viewing into memorable interactions due to striking light bending reflection. Vibrant hues can particularly reinforce brand colors, layering visual integration.

4. Automotive Parts:

Light-weight, non-corrosive, and atmospheric—the component's protective nature renders it compatible in use across various areas within the automotive industry, doubling aesthetic appeal while advancing performance advantages when installed as decorative in nature.

https://www.aluminumplate.net/a/color-coated-mirror-finish-anodized-aluminum-sheet-1060.html