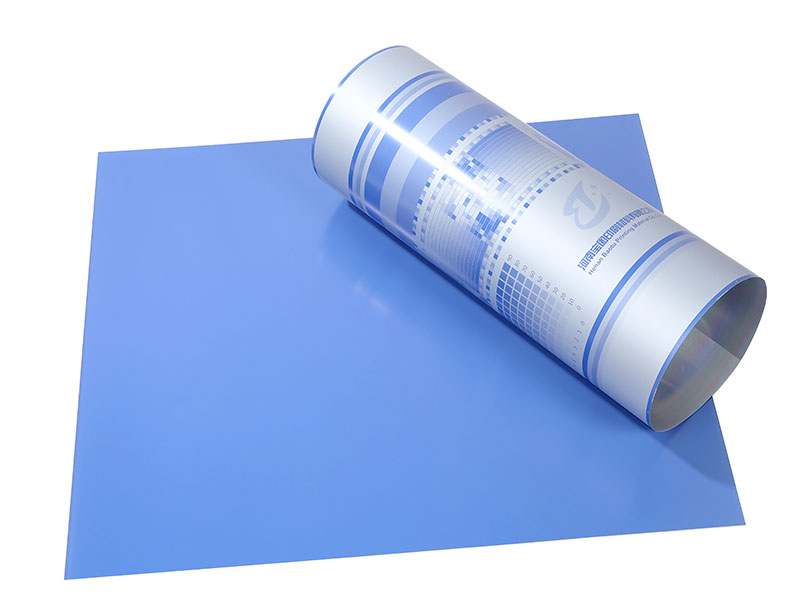

Offset Plates CTP Thermal Plates Size 605x745x0.30mm CTP Plate

In the ever-evolving world of printing technology, the quality and precision of printing plates hold paramount importance. Among the cutting-edge materials that have revolutionized the printing industry is the Offset Plates CTP Thermal Plate, specifically the 605x745x0.30mm size.

What is a CTP Thermal Plate?

CTP stands for Computer-To-Plate, a printing technology where digital files are directly transferred onto the printing plate. Thermal plates use heat-sensitive coatings to achieve precise image transfer, unlike traditional chemical processing plates. This technology enhances fidelity, sharpness, and durability, providing cost-efficient and eco-friendlier alternatives to conventional offset plates.

Technical Specification of 605x745x0.30mm CTP Thermal Plate

- Dimensions: 605mm width x 745mm height, with a thickness of 0.30mm

- Material: Aluminium alloy substrate with a thermal polymer coating

- Surface Coating: Heat-sensitive polymer optimized for laser exposure

- Imaging Technology: Direct laser etching (typically 1200 dpi or higher resolution)

- Life Span: Supports lengthy press runs exceeding 100,000 impressions depending on application and press conditions

- Tackiness, Hydrophobicity: Engineered for precise ink adherence free from unwanted surface oxidation

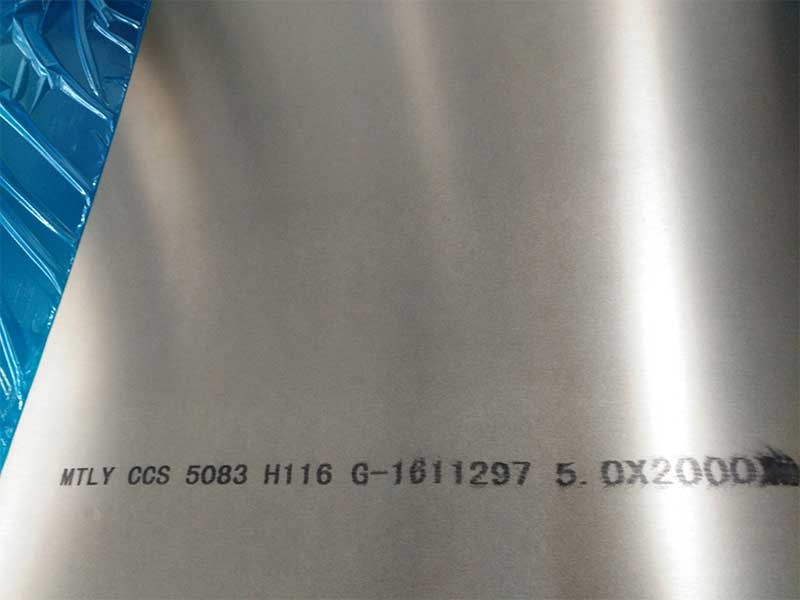

Material Alloy and Temper Characteristics

The underlying aluminium serves as a structural backbone providing durability, dimensional stability, and critical thermal conductivity. the aluminium parameters is vital to comprehend its superior performance.

| Parameter | Description | Typical Value |

|---|---|---|

| Alloy Grade | AA3003 or AA1070 series | Compliant with ASTM B209 |

| Temper | O (annealed) or H14 (hard temper) | Enhanced flex and strength |

| Thickness | Nominal 0.30mm ±0.005mm | Tight tolerance for print accuracy |

| Density | - | 2.70 g/cm³ |

| Thermal Conductivity | Facilitates heat dissipation during thermal exposure | 167 W/m·K |

Chemical Composition Table of Aluminium Alloy for Plates

| Element | Content Range (%) | Role |

|---|---|---|

| Aluminium | Bal. | Primary substrate material |

| Magnesium | 0.3-0.7 | Enhances strength and workability |

| Manganese | 0.4-1.0 | Increases corrosion resistance and mechanical properties |

| Silicon | < 0.5 | Provides casting fluidity characteristics |

| Iron | < 0.7 | Impacts dimensional tolerances |

| Others | Trace | Negligible impurities |

Functions and Distinct Advantages

High-Resolution Imaging: The thermal coating interacts optimally with diode laser imaging systems, delivering crystal-clear image definition that preserves subtle details often lost in other printing processes.

Chemical-Free Processing: Unlike older photochemical plates, these thermal plates bypass wet processing, facilitating reduced environmental risk and simplifying workshop logistics.

Long-Lasting Durability: Aluminium CTP thermal plates are designed to withstand the mechanical pressures within offset presses while supporting thousands of impressions without degradation of image quality.

Improved Ink Compatibility: The polymer coatings are engineered for hydrophobic and oleophilic balance, ensuring precise ink adhesion only on image areas and perfect water roll control in the non-image zones.

Applications in the Printing Industry

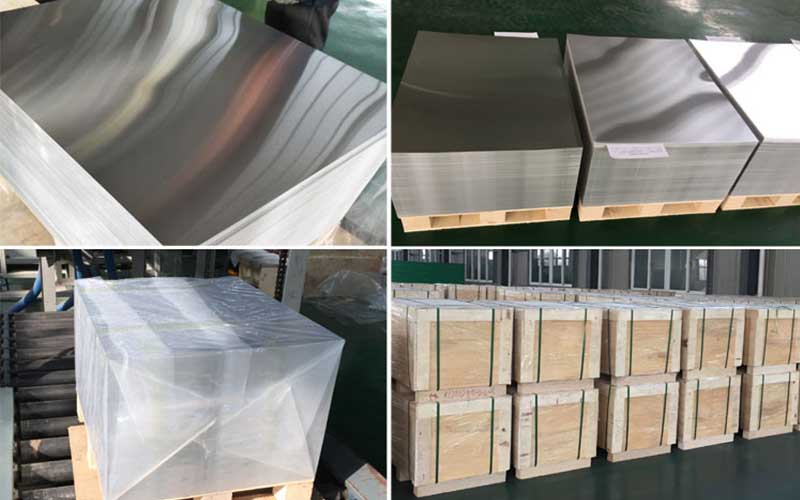

These plates, being compatible with most commercial sheet-fed offset presses and some web presses, find extensive application in:

- Commercial Printing: Production of brochures, high-end promotional materials, and catalogs demanding razor-sharp text and images.

- Packaging Industry: Particularly where metal-based rigid packaging or labels require detailed graphic communication.

- Newspaper Printing: The robustness and affordable nature facilitate high-run requirements typical to daily or weekly periodicals.

- Security Printing: The high-precision image stability benefits banknotes and document prints requiring microtext or fine Vector lines for anti-counterfeiting features.

Implementation Standards and Operational Conditions

To maximize the efficiency and print quality of the 605x745x0.30mm CTP thermal plates, industry practitioners adhere to established standards such as:

- ISO 12647-2: Governing process control for offset lithographic printing, assuring consistency.

- Standard Operating Prepress Protocols: Including density and dot gain control.

- Plate storage and usage require temperature maintenance within 10-25°C with humidity controlled between 40-60% RH to prevent premature deterioration of thermal coatings or substrate warping.

- After laser imaging, a time frame of 1-24 hours for natural oxidation improves image stability before mounting on plates sleeves or cylinders.

https://www.aluminumplate.net/a/offset-plates-ctp-thermal-plates-size-605x745x030mm-ctp-plate.html