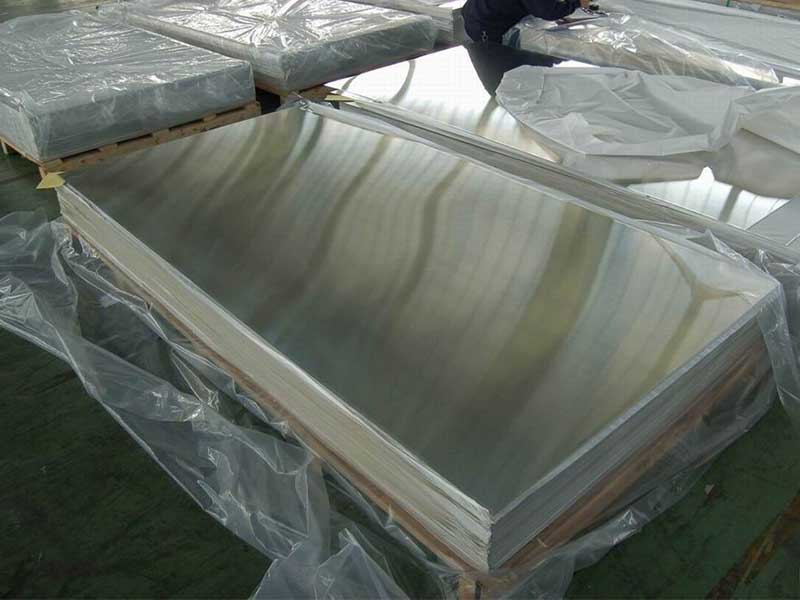

0.15-0.30 long impression double layers thermal CTP positive plate CXK G4

The CXK G4 is a double-layer thermal CTP positive plate designed for long-run, high-precision commercial and packaging printing. Covering a thickness range of 0.15–0.30 mm, it combines stable aluminum alloy base material, advanced dual-coating technology, and excellent baking resistance to deliver consistent results on both sheet-fed and web offset presses.

This overview focuses on the plate’s structure, performance features, and applications, with data presented in tables for quick reading and comparison.

Product Positioning & Highlights

The CXK G4 is built for printers who demand:

- Long impression life without frequent plate changes

- Stable performance on high-speed thermal CTP platesetters

- Reliable dot reproduction for FM and AM screening

- Excellent resistance to chemicals and repeated cleaning

| Feature Category | Description |

|---|---|

| Plate Type | Thermal CTP positive plate |

| Layer Structure | Double-layer photosensitive coating on grained & anodized aluminum |

| Thickness Range | 0.15–0.30 mm |

| Run Length | Long-run, suitable for extended impressions |

| Imaging | 830 nm thermal laser CTP systems |

| Screen Compatibility | AM up to 250 lpi, FM 20 μm or finer (equipment dependent) |

| Press Compatibility | Sheet-fed & web offset, commercial & packaging |

| Baking Capability | Yes, for extended run and UV ink printing |

Aluminum Alloy Base & Chemical Composition

The CXK G4 uses a high-purity aluminum alloy specifically tailored for printing plates. The base material is optimized for:

- Uniform graining

- Stable anodic layer

- Strong adhesion to the double-layer coating

Typical Alloy Composition (Aluminum Base Sheet)

| Element | Symbol | Typical Range (wt%) | Function in Plate Base |

|---|---|---|---|

| Aluminum | Al | Balance (≥ 97.0) | Main matrix, ensures flexibility and dimensional stability |

| Silicon | Si | 0.20 – 0.60 | Improves strength, enhances surface graining behavior |

| Iron | Fe | 0.30 – 0.70 | Increases rigidity and wear resistance |

| Copper | Cu | ≤ 0.05 | Controls grain structure, limits corrosion susceptibility |

| Manganese | Mn | 0.05 – 0.30 | Contributes to strength and fatigue resistance |

| Magnesium | Mg | 0.05 – 0.30 | Improves hardness and press durability |

| Zinc | Zn | ≤ 0.10 | Fine-tunes mechanical properties |

| Titanium | Ti | ≤ 0.05 | Grain refiner for improved flatness and uniformity |

| Others | - | ≤ 0.05 (each) | Strictly controlled trace elements |

| Impurities | - | ≤ 0.15 (total) | Kept low for stable photosensitive performance |

Note: Values are typical ranges; actual production values are controlled within narrow internal tolerances.

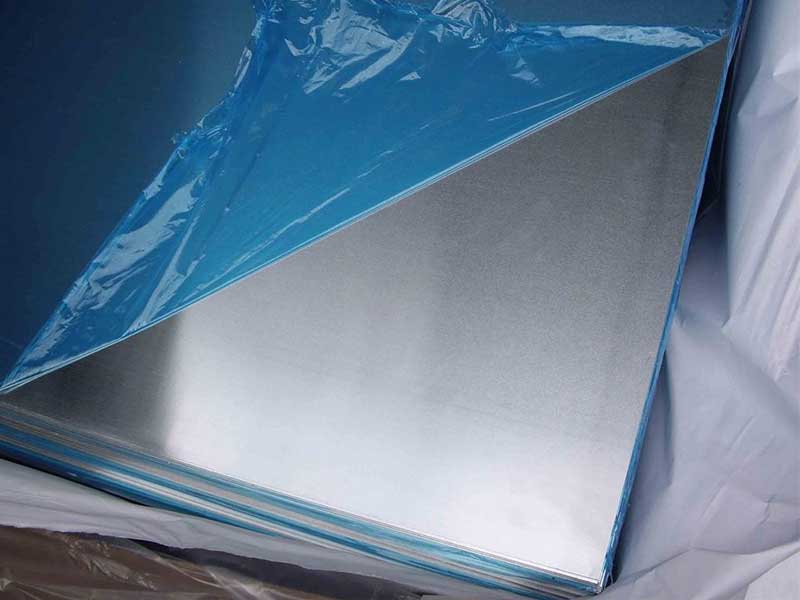

Double-Layer Coating Structure

The CXK G4’s double-layer structure is central to its performance.

Layer Architecture

| Layer | Main Function | Characteristics |

|---|---|---|

| Top Photosensitive Layer | Accepts laser imaging, forms image areas | High sensitivity, excellent dot reproduction, strong adhesion |

| Under-Coating Layer | Supports imaging, improves chemical resistance | Enhances development latitude and run length |

| Anodized Aluminum | Provides micro-porous anchor & hydrophilicity | Stable water retention, anti-corrosion protection |

| Grained Aluminum | Mechanical anchoring & water balance | Uniform roughness for quick roll-up |

This multi-layer design creates a plate that is tolerant to variations in developer activity, while maintaining a robust image area that withstands abrasion and long runs.

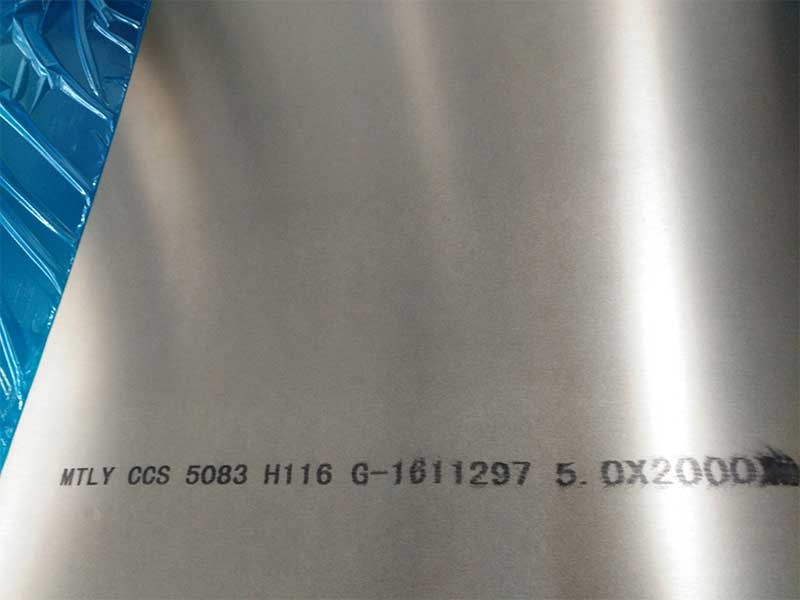

Technical Specifications

Physical Parameters

| Parameter | Typical Value / Range |

|---|---|

| Plate Thickness | 0.15 / 0.20 / 0.25 / 0.30 mm |

| Base Alloy | High-purity Al alloy (printing grade) |

| Surface Roughness (Ra) | 0.30 – 0.50 μm |

| Anodic Layer Weight | 2.5 – 3.0 g/m² |

| Coating Weight (Total) | 1.0 – 1.8 g/m² (depending on gauge) |

| Color of Coating | Blue or dark green (visual contrast) |

| Surface Finish | Matte, optimized for scanning and handling |

Imaging & Processing Parameters

| Parameter | Typical Data |

|---|---|

| Laser Wavelength | 800 – 850 nm (peak around 830 nm) |

| Laser Energy Requirement | 80 – 120 mJ/cm² (device dependent) |

| Resolution Capability | Up to 2400–2800 dpi |

| FM Screening | ≥ 20 μm (depending on CTP system) |

| AM Screening | Up to 250 lpi |

| Latent Image Stability | Excellent, suitable for normal pre-press delays |

| Developer Type | Aqueous alkaline, low-foam, dedicated or compatible thermal plate developer |

| Development Temperature | 23 – 25 °C (recommended) |

| Development Time | 20 – 35 seconds (processor dependent) |

| Finishing | Compatible with standard gum Arabic or synthetic finisher |

Performance and Durability

Run Length & Plate Life

| Condition | Typical Run Length* |

|---|---|

| Conventional inks, non-baked | Up to 200,000 impressions |

| Conventional inks, baked | Up to 400,000 impressions |

| UV inks, baked | Up to 150,000 impressions |

| Alcohol-reduced or alcohol-free dampening | High stability, equipment dependent |

* Run length values are indicative and depend on press conditions, paper choice, ink type, fountain solution, and maintenance.

Print Performance

| Performance Aspect | CXK G4 Characteristics |

|---|---|

| Dot Reproduction | Sharp 1–99% in standard printing ranges |

| Highlight Detail | Excellent retention of fine dots and smooth gradients |

| Shadow Stability | Solid density build-up with minimal dot gain |

| Water–Ink Balance | Fast roll-up, wide water window |

| Start-Up Waste | Low, quick attainment of target density |

| Scratch Resistance | High, especially after baking |

| Background Cleanliness | Non-image areas remain clean and stable over long runs |

Thermal & Chemical Behavior

The CXK G4 is engineered to maintain stability under thermal CTP exposure and during baking, while resisting typical pressroom chemistry.

Thermal and Chemical Properties

| Property | Behavior / Value |

|---|---|

| Thermal Sensitivity | Optimized for 830 nm laser systems |

| Post-Exposure Stability | Low dot gain from latent image to developed plate |

| Baking Capability | 230 – 250 °C, 5–8 minutes (oven dependent) |

| Alkali Resistance | High resistance to plate developer and cleaning agents |

| Acid Resistance | Stable with standard fountain solutions |

| Oxidation Resistance | Excellent shelf life under standard conditions |

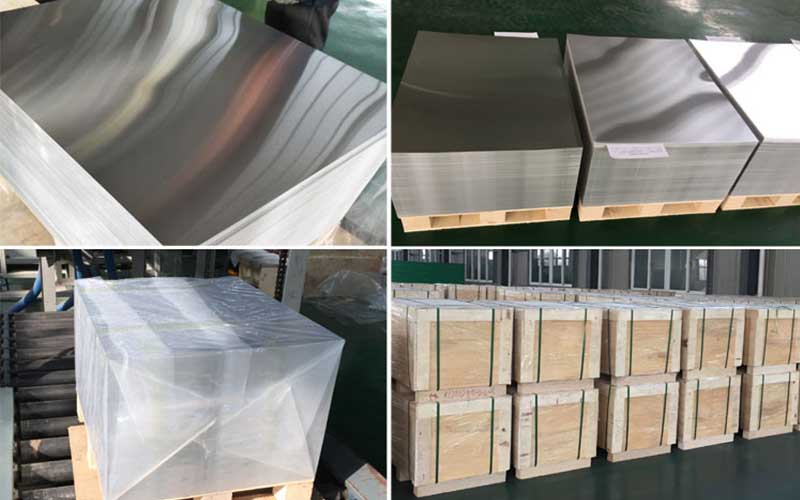

Handling, Storage & Safety

Storage Conditions

| Condition | Recommended Range |

|---|---|

| Storage Temperature | 10 – 25 °C |

| Relative Humidity | 40 – 60 % RH |

| Shelf Life | Up to 18 months from production (unopened) |

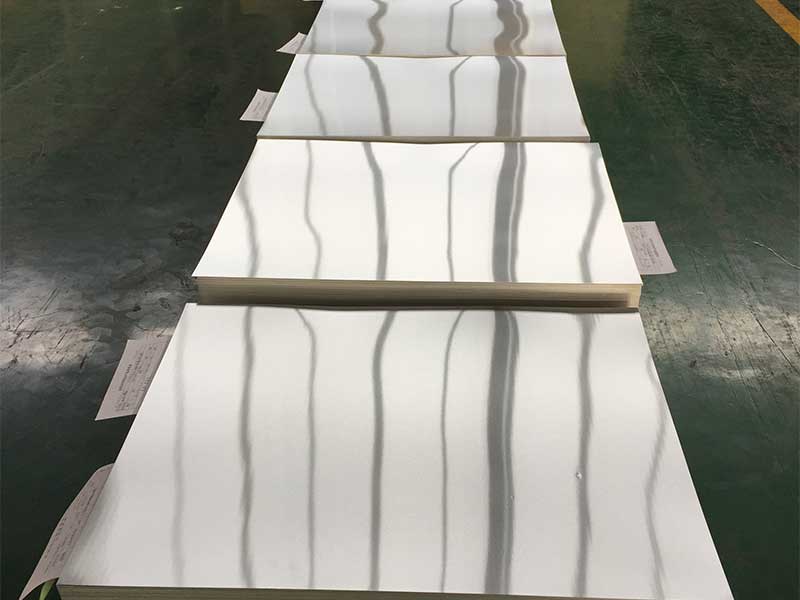

| Packaging | Light-tight, moisture-resistant carton and interleaving paper |

Handling Guidelines

| Topic | Recommendation |

|---|---|

| Light Exposure | Handle under yellow safelight; avoid direct white or UV light |

| Fingerprints | Use clean, dry gloves to avoid contamination |

| Bending & Punching | Compatible with automatic and manual systems |

| Plate Cleaning | Use approved plate cleaners; avoid strong solvents on non-baked plates |

Main Applications

The CXK G4 is versatile and well-suited for a wide range of print jobs where consistent quality, high run length, and reliable press behavior are essential.

Application Fields

| Application Area | Typical Jobs & Advantages |

|---|---|

| Commercial Printing | Magazines, catalogs, books, inserts, brochures; stable quality over large volumes |

| Packaging Printing | Folding cartons, labels, flexible packaging; good performance with thicker stocks |

| Newspaper Supplements | High-speed web printing with consistent dot control |

| Stationery & Forms | Business forms, envelopes, corporate stationery |

| High-End Advertising | Art books, product catalogs, fashion and cosmetic advertising, demanding color work |

| UV & Hybrid Printing | With baking, supports UV and hybrid inks for packaging and specialty applications |

Competitive Advantages at a Glance

| Advantage Area | CXK G4 Benefit |

|---|---|

| Long Impression Life | Designed for extended run lengths; reduces downtime and plate costs |

| High Imaging Precision | Supports high line screens and FM screening for premium print quality |

| Process Latitude | Tolerant to slight variations in developer and exposure conditions |

| Robust Coating | Double-layer system improves durability, scratch resistance, and bake-ability |

| Balanced Hydrophilicity | Clean non-image areas and fast roll-up |

| Wide Compatibility | Works on major thermal CTP platesetters and standard processors |

The 0.15–0.30 Long Impression Double Layers Thermal CTP Positive Plate CXK G4 is a robust, high-performance solution for printers seeking:

- Long, stable runs

- High-resolution imaging for both AM and FM screening

- Reliable behavior across a broad range of commercial and packaging applications

Its optimized aluminum alloy base, carefully controlled chemical composition, and advanced double-layer coating make it a strong choice for modern thermal CTP workflows where consistency, durability, and print quality are equally important.