0.6mm 3004 PVDF Coated Aluminum Sheet

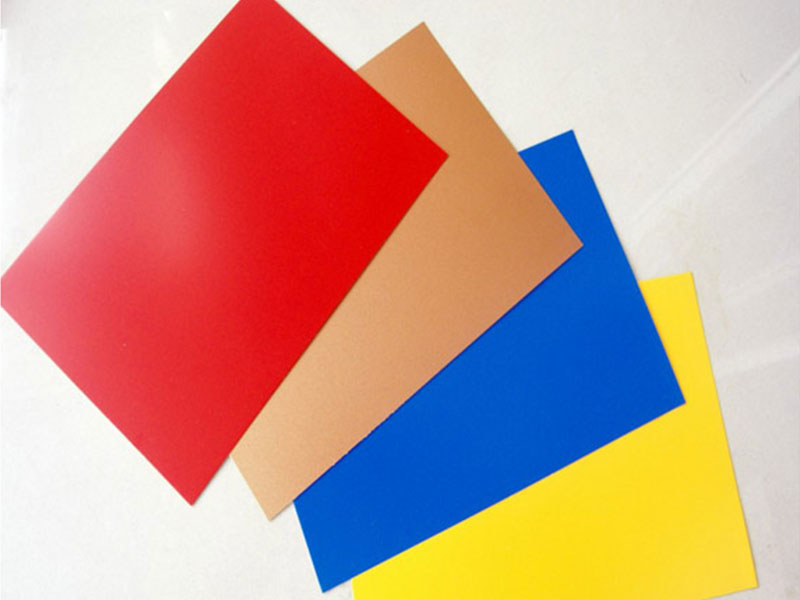

0.6mm 3004 PVDF coated aluminum sheet is a lightweight, corrosion‑resistant, and color-stable panel material widely used in building facades, roofing, ceilings, and industrial enclosures. The combination of 3004 aluminum alloy and PVDF (polyvinylidene fluoride) coating delivers excellent outdoor durability, formability, and long-lasting color retention.

3004 is an Al-Mn-Mg alloy (manganese and magnesium as the main alloying elements). It offers higher strength than 3003 while maintaining good ductility and corrosion resistance. When combined with a PVDF paint system, the surface gains superior weatherability and UV resistance, ideal for architectural use.

Typical Chemical Composition of 3004 Aluminum (wt%)

| Element | Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti | Others (each) | Others (total) | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| % | ≤ 0.30 | ≤ 0.70 | ≤ 0.25 | 1.0–1.5 | 0.8–1.3 | ≤ 0.25 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.15 | Balance |

Values are typical industry ranges; actual melt analysis may vary slightly within standard limits.

Features at a Glance

- Thin, lightweight 0.6mm gauge

- High strength-to-weight ratio from 3004 alloy

- Excellent outdoor durability with PVDF coating

- Outstanding color and gloss retention

- Strong corrosion and chemical resistance

- Good formability for bending, roll forming, and profiling

- Smooth, decorative finish available in many colors

Dimensional & Surface Specifications

Standard Dimensional Range

| Parameter | Typical Value / Range |

|---|---|

| Thickness | 0.6 mm (nominal) |

| Width | 600–1600 mm (customizable) |

| Coil Inner Diameter | 505 mm or 610 mm |

| Coil Outer Diameter | Up to 1500 mm (or as specified) |

| Coil Weight | 2–6 tons per coil (typical) |

| Length (sheet) | 1000–6000 mm or custom cut-to-length |

PVDF Coating Structure

| Layer | Typical Material | Nominal Thickness |

|---|---|---|

| Topcoat | 70%–80% PVDF resin + pigments + additives | 20–25 μm |

| Primer (top side) | Epoxy / polyester primer | 5–7 μm |

| Backcoat | Epoxy / polyester / protective lacquer | 5–10 μm |

| Total Coating (top) | Approximately 25–32 μm |

Mechanical Properties of 3004 Alloy (Typical)

For PVDF-coated 0.6mm sheet, mechanical properties are generally based on the substrate temper, most commonly H24 or H26 for building panels.

| Property | Unit | 3004 H24 (Typical) |

|---|---|---|

| Tensile Strength (Rm) | MPa | 240–285 |

| Yield Strength (Rp0.2) | MPa | ≥ 130–160 |

| Elongation (A50) | % | 7–12 |

| Density | g/cm³ | ~ 2.73 |

| Elastic Modulus | GPa | ~ 69 |

| Brinell Hardness (HB) | HB | ~ 60–70 |

Exact values depend on temper, production route, and thickness tolerance.

Coating Performance Data (PVDF)

PVDF coatings are specifically engineered for long-term outdoor exposure, making them a preferred finish for high-end architectural and industrial applications.

| Performance Item | Typical Performance | Test Reference (Typical) |

|---|---|---|

| Gloss Retention (10–20 years) | > 80% (outdoor exposure) | Natural weathering |

| Color Difference ΔE | ≤ 5 after 15–20 years | Spectrophotometer |

| Chalk Resistance | Rating ≤ 8 (ASTM scale) | ASTM D4214 |

| Salt Spray Resistance | > 1000 h no base metal exposure | ASTM B117 |

| Acid / Alkali Resistance | Excellent under normal atmospheric conditions | Lab immersion tests |

| Adhesion (cross-hatch) | Class 0–1 (no flaking) | ISO 2409 / ASTM D3359 |

| Impact Resistance | No cracking or peeling after impact | ASTM D2794 / ISO 6272 |

Why Choose 0.6mm 3004 PVDF Coated Sheet?

Balance of Strength and Formability

- 3004 alloy provides higher strength than 1xxx or 3xxx pure aluminum grades while remaining easy to bend, cut, and profile.

- 0.6mm thickness is rigid enough for many façade, cladding, and roofing systems, yet still light and cost-effective for large-area coverage.

Lightweight and Easy Handling

| Parameter | Approximate Value for 0.6mm Sheet |

|---|---|

| Areal Density | ~1.64 kg/m² |

| Panel Size Example | 1000 mm × 3000 mm |

| Weight of Example Panel | ~4.9 kg |

Handling, transportation, and installation are easier and faster than with many traditional materials such as steel or solid composite boards.

Superior Weather and UV Resistance

- PVDF coating offers long service life in harsh climates: coastal, industrial, and high-UV regions.

- Stable color and gloss help maintain building appearance for decades, reducing repainting and maintenance costs.

Design Flexibility

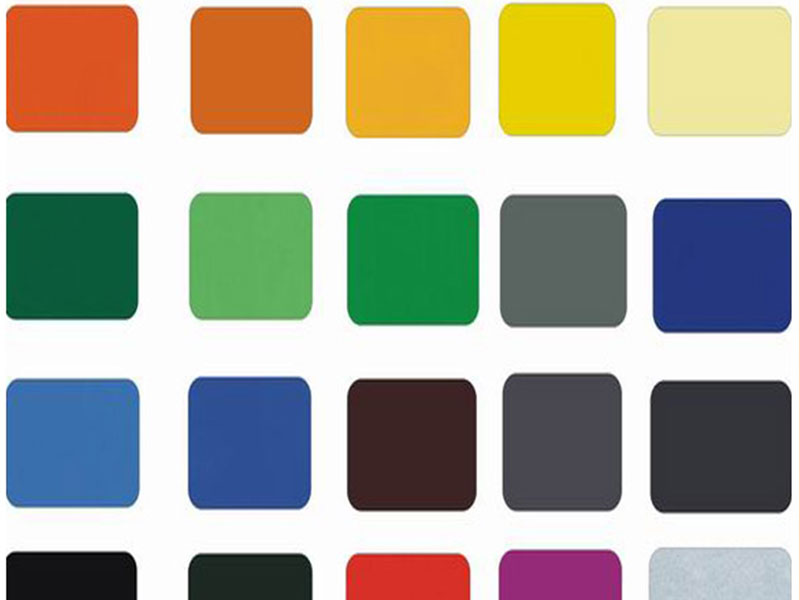

- Wide color range: solid, metallic, pearlescent, and custom RAL/ Pantone colors.

- Compatible with typical fabrication methods:

- Shearing and slitting

- Press braking and roll forming

- Punching and notching

- Suitable for flat panels, corrugated sheets, sandwich panels, and cassette systems.

Typical Applications

Architectural Facades and Cladding

| Application Area | Benefits of 0.6mm 3004 PVDF Sheet |

|---|---|

| Exterior wall cladding | Long-lasting color, corrosion resistance, light weight |

| Curtain wall panels | Excellent flatness, easy fabrication, clean appearance |

| Balcony and parapet panels | Good rigidity at low thickness, safe and durable |

| Column covers and soffits | Consistent color with other façade elements |

Roofing and Ceiling Systems

| Application | Advantages |

|---|---|

| Standing seam roofs | Formable alloy, stable PVDF surface |

| Corrugated / trapezoidal roof | Lightweight, corrosion resistant |

| Interior metal ceilings | Decorative colors, easy cleaning, fire-safe substrate |

Industrial and Commercial Uses

| Sector | Example Uses |

|---|---|

| Industrial plants | Wall and roof panels, equipment enclosures |

| Warehouses and logistics | Claddings, dock shelters, canopy covers |

| Transportation | Trailer panels, container skins, bus stations |

| Signage & branding | Sign boards, fascias, display panels |

Surface Finish Options

| Option Type | Description |

|---|---|

| Standard solid color | Matt / satin / high gloss in standard shades |

| Metallic | Aluminum flakes for metallic visual effect |

| Special textures | Stucco embossing, wood grain, stone-like print |

| Backside finish | Protective coating or primer for bonding |

The PVDF system can be matched to corporate identity colors or existing façade schemes, supporting cohesive architectural design.

Processing and Fabrication Notes

- Suitable for most common sheet-metal processes: cutting, bending, roll forming, and drilling.

- Minimum bending radius should respect coated sheet guidelines to avoid micro-cracking of the paint film; radius depends on die design and bending direction.

- Pre-punched and pre-formed panels should be handled with soft pads to protect the PVDF surface and prevent scratching.

- Edge protection and proper sealing are recommended in aggressive environments, such as marine or heavily industrial locations.

Storage, Handling, and Installation

| Aspect | Recommendation |

|---|---|

| Storage environment | Dry, clean, covered, away from direct moisture |

| Stacking | Use spacers; avoid hard contact between coils |

| Protective film | Remove after installation or within recommended time to avoid residue |

| Cutting | Use sharp tools; blow off chips to protect finish |

| Fasteners | Corrosion-compatible screws and rivets (e.g. stainless steel or coated fasteners) |

0.6mm 3004 PVDF coated aluminum sheet is a high-performance, versatile material designed for architectural, industrial, and commercial cladding and roofing. The 3004 alloy substrate ensures reliable mechanical strength and formability, while the PVDF coating offers exceptional weather resistance, color stability, and long-term aesthetics.

For projects demanding lightweight construction, durable surfaces, and minimal maintenance, this product provides a balanced, cost-effective solution that remains stable and attractive over many years of service.

https://www.aluminumplate.net/a/06mm-3004-pvdf-coated-aluminum-sheet.html