Embossed aluminum sheet 0.1mm 0.2mm 2mm 6082 T6 Thin

Embossed aluminum sheet in alloy 6082 T6 combines a high-strength structural alloy with a functional decorative surface. In thin gauges such as 0.1 mm, 0.2 mm, and 2 mm, it is ideal for lightweight panels, decorative cladding, protective covers, and technical applications where both appearance and performance matter.

Product name: Embossed aluminum sheet 0.1mm 0.2mm 2mm 6082 T6 Thin

Alloy series: 6xxx (Al-Mg-Si) heat-treatable alloy

Temper: T6 (solution heat-treated and artificially aged)

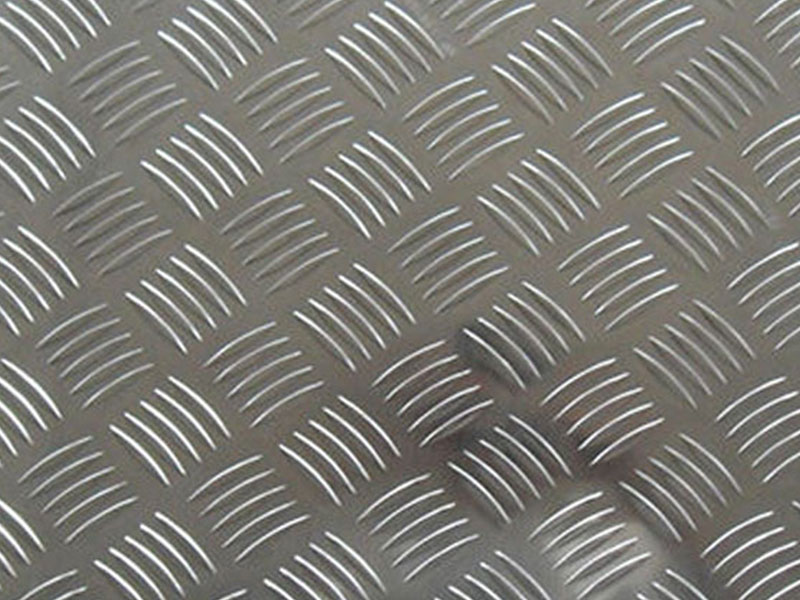

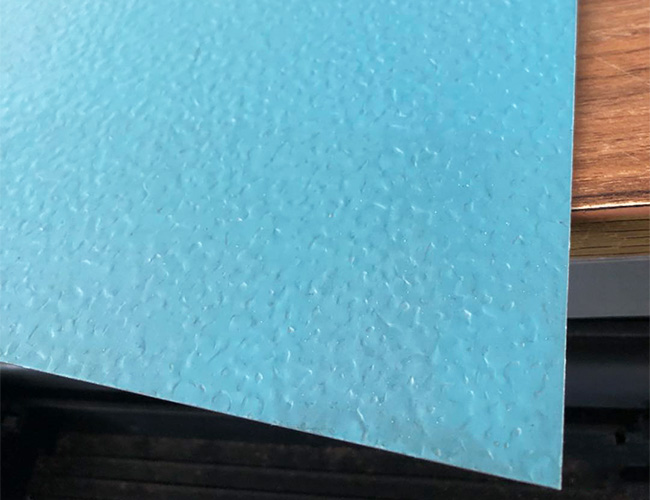

Surface: Embossed pattern (e.g. orange peel, stucco, diamond, or custom)

Core Advantages

- High strength-to-weight ratio compared with 1xxx/3xxx embossed sheets

- Good corrosion resistance in indoor and many outdoor environments

- Excellent surface grip due to embossing, reducing slip risk

- Enhanced stiffness and dent resistance versus plain thin sheet

- Good machinability and cuttability for precision components

- Suitable for post-painting, powder coating, and adhesive bonding

2. Typical Chemical Composition of 6082 Alloy

Values are nominal ranges according to common 6082 specifications. Actual values depend on the melt and manufacturing standard (EN, ASTM, etc.).

| Element | Symbol | Typical Range (wt%) |

|---|---|---|

| Aluminum | Al | Balance |

| Silicon | Si | 0.70 – 1.30 |

| Magnesium | Mg | 0.60 – 1.20 |

| Manganese | Mn | 0.40 – 1.00 |

| Iron | Fe | ≤ 0.50 |

| Copper | Cu | ≤ 0.10 |

| Chromium | Cr | ≤ 0.25 |

| Zinc | Zn | ≤ 0.20 |

| Titanium | Ti | ≤ 0.10 |

| Others (each) | - | ≤ 0.05 |

| Others (total) | - | ≤ 0.15 |

alloying effects:

- Mg + Si form Mg2Si, providing age-hardening capability and high strength in T6 temper.

- Mn refines grain structure, improving toughness and consistency.

- Low levels of Cu, Fe, Zn maintain good corrosion resistance and weldability.

3. Mechanical Properties (Typical Values, 6082 T6)

Values are indicative for flat sheet; thin gauges may show slight variations depending on production route.

| Property | Unit | Typical Value (T6) |

|---|---|---|

| Tensile strength, Rm | MPa | 295 – 340 |

| 0.2% proof stress, Rp0.2 | MPa | 240 – 280 |

| Elongation (A50) | % | 6 – 10 |

| Elastic modulus | GPa | ~70 |

| Brinell hardness (HBW) | - | 90 – 100 |

| Density | g/cm³ | ~2.70 |

| Poisson’s ratio | - | ~0.33 |

Implication for users:

Compared with 1xxx/3xxx embossed sheets, 6082 T6 delivers significantly higher yield and tensile strength, allowing thinner gauge for the same load capacity or higher safety margin at equal thickness.

4. Available Thicknesses And Dimensional Range

While this product focuses on 0.1 mm, 0.2 mm, and 2 mm, other gauges may be available on request.

| Parameter | Unit | Typical Range / Option |

|---|---|---|

| Thickness | mm | 0.10, 0.20, 2.0 (other gauges on request) |

| Width | mm | 500 – 1500 (custom widths possible) |

| Coil inner diameter | mm | 305 / 508 for thin coil (0.1–0.2 mm) |

| Sheet length | mm | 500 – 6000 (cut-to-length) |

| Emboss pattern | - | Stucco, orange peel, diamond, or specified pattern |

| Tolerance on thickness | mm | ±0.02 (0.1–0.2 mm); ±0.05 (2 mm typical) |

| Edge type | - | Mill edge, slit edge, deburred on request |

5. Surface And Emboss Pattern

The embossing is created by pressing the sheet between patterned rollers. This changes surface topography without significantly reducing overall thickness.

Typical surface options:

| Feature | Option / Description |

|---|---|

| Pattern type | Stucco/orange peel, diamond, small tear drop, custom |

| Surface finish | Mill finish, light brushing, pre-coated on request |

| Reflectivity | Medium; diffuse reflection due to embossed texture |

| Slip resistance | Increased coefficient of friction vs flat sheet |

| Coating compatibility | Suitable for powder coating, liquid paint, and adhesive films |

Benefits of embossing:

- Hides small scratches and fingerprints

- Improves visual uniformity across large panels

- Reduces glare due to diffuse light scattering

- Adds rigidity; embossed profile behaves stiffer than flat sheet of the same gauge

6. Performance Characteristics

6.1 Mechanical Performance

| Performance Aspect | 6082 T6 Embossed Sheet |

|---|---|

| Strength | High, suitable for light structural use |

| Stiffness | Enhanced by both alloy and emboss pattern |

| Impact resistance | Good for thin technical covers and panels |

| Fatigue behavior | Better than 1xxx/3xxx for dynamic loads when properly designed |

6.2 Corrosion Resistance

6082 offers good general corrosion resistance in neutral and mildly aggressive environments.

| Environment | Performance | Notes |

|---|---|---|

| Indoor / dry | Excellent | Long service life with minimal maintenance |

| Outdoor / urban | Very good | Optional coating extends life and appearance |

| Marine atmosphere | Good with coating | Recommended anodizing or paint system |

| Chemical exposure | Case-dependent | Check compatibility with specific chemicals |

6.3 Thermal And Electrical Behavior

| Property | Unit | Typical Value |

|---|---|---|

| Thermal conductivity | W/(m·K) | ~170 – 200 |

| Coefficient of thermal expansion | 10⁻⁶/K | ~23 – 24 |

| Electrical conductivity | % IACS | ~30 – 40 |

Good thermal conductivity makes thin 6082 sheets useful for heat-spreading covers, enclosures, and decorative shields in thermal management systems.

| Item | Specification |

|---|---|

| Alloy | 6082 |

| Temper | T6 |

| Product form | Embossed sheet / coil |

| Thickness | 0.1 mm, 0.2 mm, 2 mm (others on request) |

| Width | Up to approx. 1500 mm typical |

| Standards (typical) | EN 485 / EN 573 or equivalent mill standard |

| Flatness | Controlled according to sheet thickness and width |

| Surface quality | Free from heavy scratches, rolling defects, and visible inclusions |

| Packaging | Coil or sheet stacks, interleaved with paper/film, seaworthy packing on request |

8. Processing And Fabrication

6082 T6 embossed thin sheet is compatible with most common fabrication processes:

| Process | Suitability | Comments |

|---|---|---|

| Shearing / slitting | Excellent | Clean cuts with appropriate blade clearance |

| Punching | Good | Use sharp tools; emboss pattern slightly affects burr shape |

| Bending | Moderate | 2 mm: good; 0.1–0.2 mm: easily formable but requires support to avoid print-through |

| Deep drawing | Limited | Embossing and T6 temper reduce heavy drawability; light forming is fine |

| Machining (milling, drilling) | Very good | 6082 is one of the most machinable 6xxx alloys |

| Welding (TIG/MIG) | Possible | Strength in HAZ reduces compared to T6 base metal; design accordingly |

| Adhesive bonding | Very good | Embossing increases effective bonding area; proper cleaning is essential |

For tight-radius bending or severe forming, a softer temper (e.g. T4, O) may be preferable; however, for this product the focus is on structural T6 performance.

9. Applications

Thanks to its combination of strength, light weight, and textured surface, embossed 6082 T6 thin sheet is used across many sectors.

9.1 Architectural And Interior

- Decorative wall and ceiling panels

- Elevator interiors and wall guards

- Column wraps and decorative cladding

- Door skins, cabinet fronts, and partitions

Benefits:

- Embossing masks small dents and scratches

- Lightweight panels reduce load on structures

- Easy to clean, with a modern metallic appearance

9.2 Transportation

- Interior panels in buses, trains, and commercial vehicles

- Non-slip floor or wall protection panels in service areas

- Decorative trim strips and protective covers

Benefits:

- Weight reduction improves fuel efficiency

- High strength at 2 mm thickness for robust panels

- Good resistance to wear and moderate impact

9.3 Industrial And Equipment Enclosures

- Machine guards and safety covers

- Equipment housings and access panels

- HVAC decorative covers and duct cladding

- Heat-spreading covers on electronic cabinets

Benefits:

- Emboss pattern increases rigidity of thin panels

- Good machinability for precise cutouts and mounting holes

- Suitable for powder coating to match corporate colors

9.4 Consumer And Commercial Products

- Appliance rear covers and technical panels

- Decorative boards, display fixtures, and POS materials

- Toolboxes, instrument cases, and light-duty cases

Benefits:

- Attractive textured finish straight from the mill

- Reduced need for complex surface treatments

- Easily processed by small workshops and OEMs

10. Why Choose Embossed 6082 T6 Over Plain Or Low-Strength Alloys?

| Criterion | Embossed 6082 T6 | Plain 1xxx / 3xxx Flat Sheet |

|---|---|---|

| Strength | High | Low to medium |

| Stiffness at same thickness | Higher (alloy + emboss) | Lower |

| Appearance | Textured, hides marks | Shows every scratch/dent |

| Slip resistance | Good | Lower |

| Weight | Very low (all aluminum) | Similar, but may need thicker gauge |

| Formability | Moderate in T6 | Typically better for soft 1xxx/3xxx |

| Structural capability | Suitable for light structures | Limited |

If your application requires both decorative appearance and meaningful mechanical strength, embossed 6082 T6 provides a more capable solution than standard embossed 1xxx/3xxx products.

11. Selection Guide By Thickness

| Thickness | Typical Use Cases | Considerations |

|---|---|---|

| 0.1 mm | Decorative foils, light shielding, wrapping of profiles, label plates | Extremely flexible; handle carefully; ideal where weight must be minimized |

| 0.2 mm | Light cladding, façade lamellas, appliance covers, interior decorative sheets | Good compromise between rigidity and flexibility; supports light bending |

| 2 mm | Structural panels, machine guards, vehicle interior panels, floor and wall protection | High stiffness and impact resistance; suitable where mechanical performance is critical |

- High strength in a thin format: 6082 T6 provides far greater load capacity than common non-heat-treatable alloys at similar thickness.

- Functional embossed surface: Improves visual quality, grip, and stiffness while hiding minor handling marks.

- Versatile processing: Easily cut, punched, machined, and coated, suitable for both industrial and decorative products.

- Lightweight and corrosion-resistant: Ideal for architectures, transportation, and equipment applications where long-term reliability is important.

Embossed aluminum sheet 0.1 mm, 0.2 mm, and 2 mm in 6082 T6 temper delivers a balanced solution for customers who need attractive, lightweight, and mechanically robust thin sheet for modern engineering and design projects.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-01mm-02mm-2mm-6082-t6-thin.html