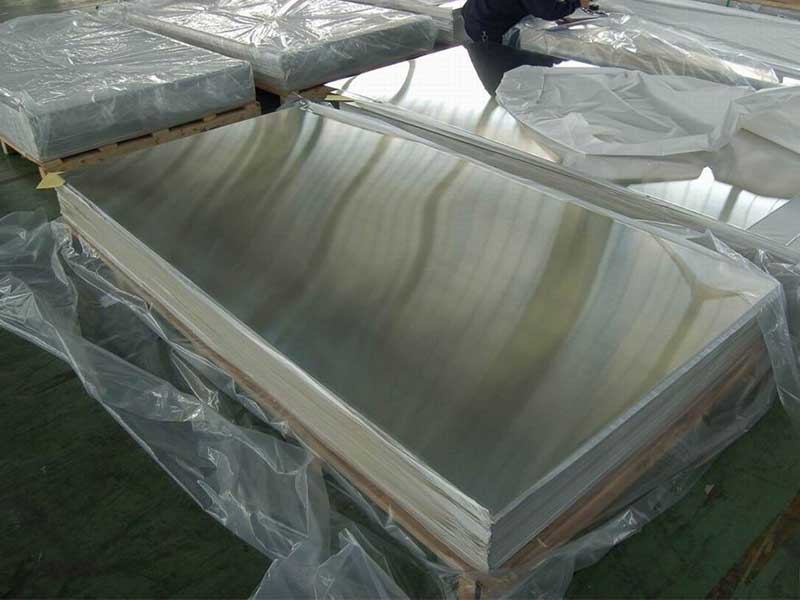

1060 Alloy Anodized Aluminum Sheet

1060 Alloy Anodized Aluminum Sheet: An Expert’s Insight into Its Unique Benefits and Technical Excellence

When selecting aluminum sheets for various industrial or decorative applications, one alloy consistently stands out: the 1060 alloy anodized aluminum sheet. While widely recognized for its superior corrosion resistance and excellent surface workmanship, delving deeper into the technical nuances uncovers why this material is an industry favorite beyond its well-known general advantages.

What Makes 1060 Alloy Aluminum Special?

The 1060 aluminum alloy belongs to the 1xxx series, indicating its exceptional purity—at least 99.6% aluminum. This inherently grants it some outstanding properties such as superior thermal and electrical conductivity, corrosion resistance, and remarkable workability. The high purity translates not just into aesthetic brilliance but practical perks like enhanced recyclability and ecological friendliness, positioning the 1060 alloy as a sustainable choice for many manufacturers.

Technical Spotlight: The Anodizing Transformation

Many users immediately associate anodizing with emphasizing surface color and finish, but anodizing the 1060 alloy sheet is a lot more technically driven:

- Enhanced Corrosion Resistance: Anodizing converts the aluminum surface into a robust layer of aluminum oxide, significantly improving resistance not just in everyday environments but harsh industrial ones.

- Electrical Insulation: Through anodizing, this sheet gains surface insulation properties. This is crucial in applications where electrical isolation is necessary, like in certain electronic housings or architectural applications.

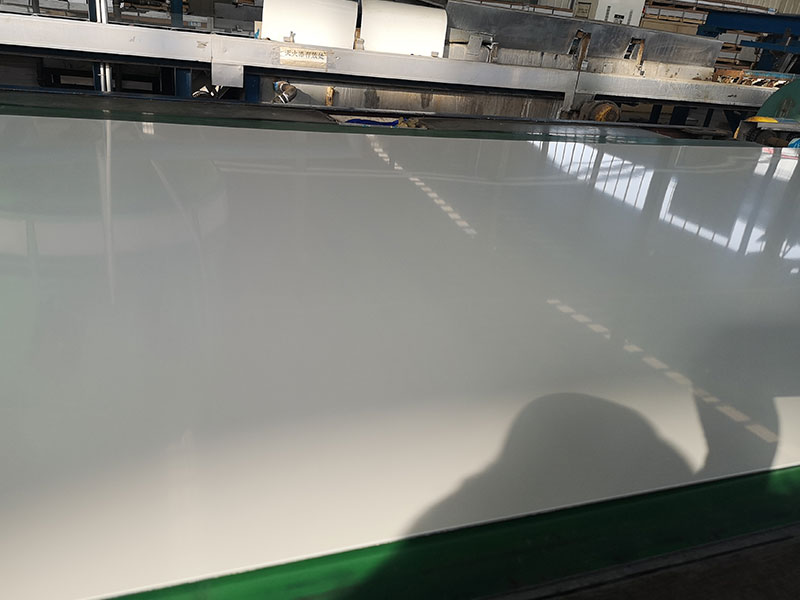

- Thickness and Uniformity Control: Compared to other alloys, the 1060 is uniquely suitable for anodizing due to its uniform chemical composition, allowing manufacturers to achieve exceptionally consistent anodic layers with predictable mechanical properties.

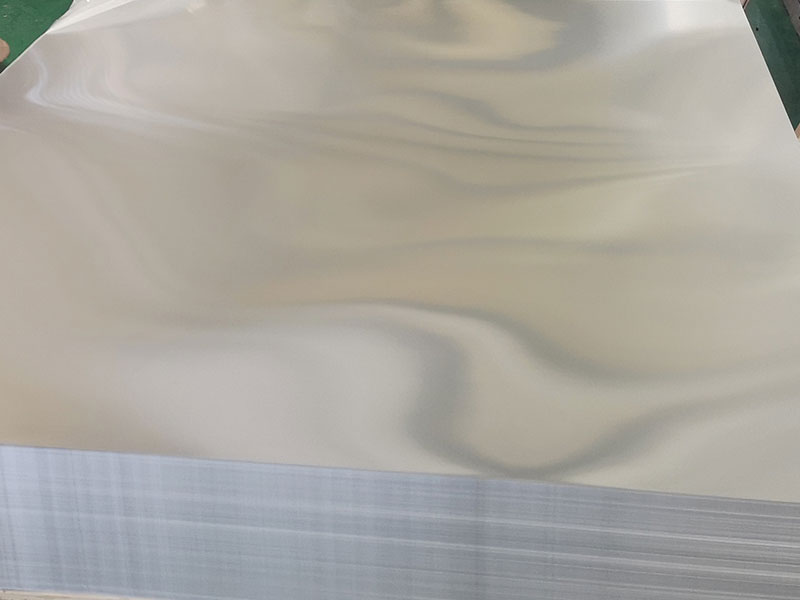

- Improved Surface Hardness: Post-anodizing, the sheet surface boasts hardness values appreciably greater than untreated metal, contributing to enhanced wear resistance without sacrificing flexibility.

Distinctive Manufacturing Techniques Impact Performance

The production process for 1060 alloy anodized sheets involves controlled rolling practices, where maintaining grain alignment boosts mechanical strength while preserving ductility. Unlike other lower-purity analogs, 1060 sheets minimize inclusions and impurities, a distinction critical for heat-treated anodizing processes to avoid surface pitting or uneven texture after anodization.

Additionally, manufacturers optimize parameters like bath electrolyte composition, voltage cycles, and sealing methods, harmonized especially for the 1060 alloy’s characteristics. This tailored approach means finished products deliver both visual appeal alongside industrial versatility, open to architectural claddings, kitchen appliances, electrical panels, and ligthweight transportation parts.

Applications Where 1060 Anodized Aluminum Shines

- Architectural Facades: The blend of luster, corrosion resistance, and durability in anodized 1060 sheets makes them ideal for exterior and interior decorative panels.

- Electrical Components: Due to its insulation after anodizing and high electrical and thermal conductivity, it’s the favored aluminum for housings and PCB mounts.

- Culinary Equipment and Food Processing: The non-toxic nature and abrasion resistance ensure safety and longevity.

- Lightweight Transportation: Offering an excellent strength-to-weight ratio, chil-friendly forming characteristics, and superior corrosion properties, anodized 1060 sheets are often applied in railcars, marine environments, and aircraft interiors.

Why Choose 1060 Alloy Anodized Aluminum Sheet Over Alternatives?

In markets offering various aluminum alloys and surface treatments, selecting 1060 anodized sheets balances cost, performance, and sustainability. Higher purity means fewer internal defects, translating into long product life cycles and superior recyclability. Anodizing—not simply a cosmetic finish—actively extends functional usage, protecting critical structural or decorative elements where surface focused alloys typically falter under mechanical or environmental stressors.

The 1060 alloy anodized aluminum sheet is far more than “pure aluminum with a coating.” Its combination of elemental purity,technical-recognized anodizing compatibility, and predictable performance creates versatile, reliable, and eco-sensitive solutions suited for aggressive environments and tasteful design needs alike. For innovators requiring an aluminum solution where brilliance meets durability - 1060 anodized aluminum is a definitive and intelligent investment.

Discover the unique technical advantages and diverse applications of the 1060 alloy anodized aluminum sheet. Explore why this pure aluminum product is ideal for industries seeking durability, heat resistance, and aesthetic appeal.

https://www.aluminumplate.net/a/1060-alloy-anodized-aluminum-sheet.html