7075 t73 aluminum sheet mill finished

7075-T73 aluminum sheet (mill finished) is a premium, high-strength wrought aluminum product engineered for demanding structures where strength-to-weight ratio, stress corrosion cracking (SCC) resistance, and dimensional reliability matter. Built on the Al-Zn-Mg-Cu alloy system, 7075 is widely known as one of the strongest commercially available aluminum alloys. The T73 temper (overaged condition) is specifically chosen when users want improved corrosion and SCC resistance compared with peak-strength tempers, while retaining excellent mechanical strength for critical parts.

"Mill finished" indicates the sheet is supplied with the as-rolled surface-clean, metallic, and suitable for many structural, machined, or coated applications. It's a practical choice for customers who plan to machine, paint, anodize, or clad/coat downstream and want to minimize unnecessary surface-processing cost upfront.

What Makes 7075-T73 Mill Finished Sheet Valuable

Features (Customer-Focused)

- High structural strength: ideal for heavily loaded parts where weight reduction is essential.

- Improved SCC resistance (T73): safer choice than peak-aged tempers in humid or corrosive service.

- Good fatigue performance: supports cyclic loading in airframes, tooling, and sporting components.

- Excellent machinability: chips cleanly, holds tolerances well, supports high-feed CNC operations.

- Mill finish flexibility: cost-effective base surface for machining, painting, conversion coating, or anodizing.

Chemical Composition (Typical Limits)

7075 is defined by its Zn-Mg-Cu strengthening system. The balance between these elements is what drives its high strength and heat-treat response.

| Element | Typical Spec Range (wt. %) | Role in Alloy |

|---|---|---|

| Zn | 5.6–6.1 | Primary strength contributor (precipitation hardening) |

| Mg | 2.1–2.5 | Works with Zn to form strengthening phases |

| Cu | 1.2–1.6 | Boosts strength, affects corrosion behavior |

| Cr | 0.18–0.28 | Improves stress corrosion and grain control |

| Fe | ≤ 0.50 | Impurity control (affects toughness if high) |

| Si | ≤ 0.40 | Impurity control |

| Mn | ≤ 0.30 | Impurity control / minor strengthening |

| Ti | ≤ 0.20 | Grain refinement |

| Al | Remainder | Base metal |

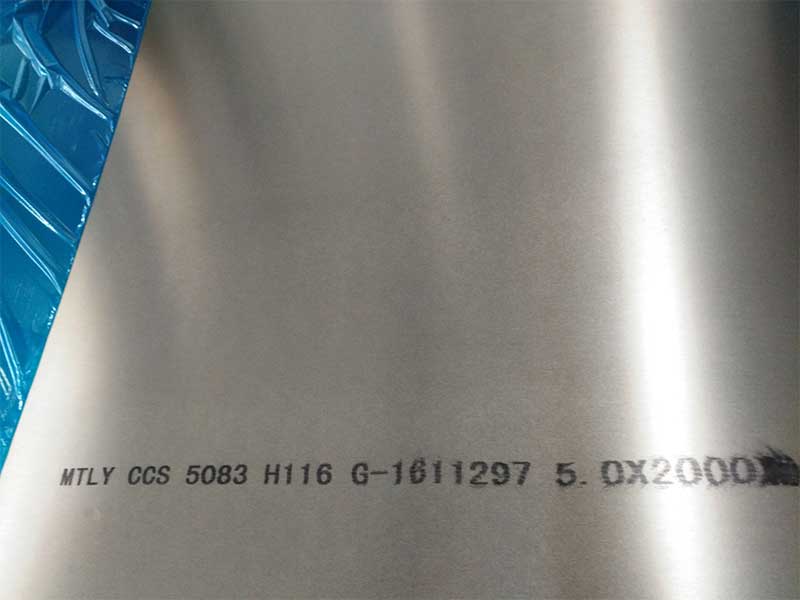

Note: Actual melt chemistry can vary slightly by mill practice and applicable standard; request mill test certificates (MTC) for compliance verification.

Temper and Metallurgy: Why T73?

The T73 temper is an overaged precipitation-hardened condition. In simple terms, the alloy is heat treated to reach a microstructure that sacrifices a small amount of peak strength (vs. T6/T651) in exchange for significantly improved SCC resistance and more robust corrosion performance in aggressive environments.

This makes 7075-T73 especially suitable for:

- high-stress parts exposed to moisture or coastal atmospheres,

- thick sections where SCC risk is higher,

- safety-critical components requiring stable long-term behavior.

Mechanical Properties (Typical)

Properties depend on thickness, grain direction (L/T), and processing route. The following table summarizes typical values commonly associated with 7075-T73 sheet.

| Property | Typical Value | Notes |

|---|---|---|

| Ultimate tensile strength (UTS) | 510–570 MPa | Thickness and direction dependent |

| Yield strength (0.2% offset) | 435–505 MPa | T73 optimized for SCC resistance |

| Elongation | 7–13% | Higher elongation generally in thinner gauges |

| Hardness | ~150–170 HB | Approximate range |

| Fatigue strength (rotating bending) | ~150–190 MPa | Highly surface-finish dependent |

| Density | 2.81 g/cm³ | Lightweight vs. steels |

Physical & Thermal Performance (Typical)

7075 is often chosen for structural strength rather than conductivity, but knowing thermal behavior helps in machining, joining, and service temperature design.

| Parameter | Typical Value | Design Implication |

|---|---|---|

| Elastic modulus | ~71–72 GPa | Stiffness similar to most aluminum alloys |

| Thermal conductivity | ~130 W/m·K | Lower than 6xxx; still good for heat spreading |

| Electrical conductivity | ~33–38 %IACS | Useful for grounding but not a pure conductor |

| Coefficient of thermal expansion | ~23.5 µm/m·K | Consider in tight-tolerance assemblies |

| Service temperature (practical) | up to ~120°C (often used lower) | Strength decreases with elevated temperature exposure |

Technical Specifications (Typical Supply Capabilities)

Availability varies by mill and region, but the following are commonly requested parameters for mill-finished sheet.

| Item | Typical Range / Option |

|---|---|

| Product form | Sheet / plate-like sheet (depending on thickness) |

| Temper | T73 (also seen as T7351/T7651 in other product forms) |

| Thickness range | Commonly ~0.5 mm to 6.0 mm (wider possible by mill) |

| Width | Commonly up to ~1500–2000 mm |

| Length | Cut-to-length or coil (depending on gauge and mill) |

| Surface | Mill finish (as-rolled), protective film optional |

| Standards (common references) | ASTM B209 and aerospace equivalents depending on application |

If you need aerospace qualification, confirm the exact standard, inspection class, and certification requirements at RFQ stage.

Corrosion Behavior & Surface Considerations

7075 is a high-strength alloy and, like most Al-Zn-Mg-Cu grades, benefits from proper surface protection in corrosive environments. The T73 temper improves resistance to SCC, but good practice still includes:

- Conversion coating (chromate or trivalent alternatives) for paint adhesion and corrosion protection

- Anodizing (note: hard anodize can influence fatigue if not controlled)

- Primer + topcoat paint systems for marine/coastal exposure

- Sealants and isolation when in contact with dissimilar metals (galvanic corrosion control)

Mill finished sheet is a strong starting point for these coatings because it avoids unnecessary pre-finishing cost. However, users should plan surface prep (cleaning, etching, deoxidizing) appropriate to the final coating system.

Machining, Forming, and Fabrication Notes

| Operation | 7075-T73 Performance | Practical Guidance |

|---|---|---|

| CNC machining | Excellent | Use sharp tooling; manage heat; high-quality chips |

| Forming/bending | Limited vs. 5xxx/6xxx | Use generous bend radii; test per thickness/direction |

| Welding | Generally not recommended | Strength loss and cracking risk; prefer mechanical fastening |

| Riveting/fastening | Very good | Common in aircraft structures; ensure galvanic isolation |

| Adhesive bonding | Good with correct prep | Surface prep critical; control contamination |

Typical Applications (Where It Fits Best)

7075-T73 mill finished sheet is commonly specified for parts that need high strength and reliable corrosion/SCC performance:

- Aerospace structural sheet components: brackets, doublers, stiffeners, frames (non-welded)

- Defense and tactical equipment: lightweight structural panels and machined subcomponents

- High-performance tooling and fixtures: jigs, precision plates, wear-resistant fixtures

- Motorsport and performance vehicles: suspension brackets, load-bearing mounts, structural inserts

- Sporting goods: high-end components where weight and stiffness matter (e.g., performance hardware)

Customer Benefits: Why Choose This Product

| Benefit | What It Means in Practice |

|---|---|

| Strong and lightweight | Higher payload, faster motion, lower fuel/energy use |

| T73 temper reliability | Reduced SCC risk and better long-term durability |

| Mill finish cost efficiency | Pay for surface finishing only if/when needed |

| Good machinability | Lower machining time, better tool life, tighter tolerances |

| Proven industry adoption | Well-understood behavior; easier qualification and design |

Selecting the Right 7075-T73 Sheet: Quick Checklist

- Confirm thickness and grain direction for bending and fatigue-sensitive parts.

- Specify certification needs (MTC, heat lot traceability, aerospace inspection requirements).

- Plan surface protection if exposed to salts, humidity, or dissimilar-metal contact.

- Avoid welding in the design stage; use fasteners, bonding, or mechanical joints.

- Define flatness/tolerance targets early for precision assemblies.

7075 T73 aluminum sheet (mill finished) is a high-performance choice for structural, machined, and fatigue-loaded components where high strength must be paired with improved SCC resistance. It's best suited for aerospace-style design philosophies-mechanically fastened assemblies, controlled surface protection, and tight process discipline. For customers who need a strong, versatile base material that can be machined or coated to final requirements, mill-finished 7075-T73 delivers an excellent balance of performance, reliability, and cost control.

https://www.aluminumplate.net/a/7075-t73-aluminum-sheet-mill-finished.html