Alloy 5754 Temper H11 H111 Aluminium Plate

Alloy 5754 H11/H111 aluminium plate is a popular marine- and transport-grade wrought aluminum-magnesium alloy designed for strong corrosion resistance, reliable formability, and stable performance in welded structures. Often chosen where painted or anodized surfaces must stay clean and durable, 5754 plate delivers a balanced mix of moderate strength, excellent seawater resistance, and low maintenance across long service life.

Compared with many high-strength aluminum alloys, 5754 is valued for its predictable fabrication behavior: it cuts cleanly, bends well, and welds without complicated post-treatments. The H11 and H111 tempers are especially practical for customers who need a "work-ready" plate condition with controlled properties and consistent flatness.

5754 is an Al-Mg alloy (5xxx series). Magnesium is the principal alloying element, giving this grade its characteristic corrosion performance and solid strength without heat treatment.

Temper descriptions

- H11 indicates strain hardened to a controlled, light level, improving strength compared with fully annealed material while maintaining good ductility.

- H111 indicates a very lightly strain-hardened condition, usually close to annealed but with improved property stability after processing.

These tempers are widely used for plates intended for forming, welded assemblies, and marine exposure-where consistent toughness and corrosion resistance matter as much as strength.

Features and Performance Highlights

| Feature | What it means for customers | Typical value proposition |

|---|---|---|

| Strong corrosion resistance | Excellent performance in marine atmosphere and industrial humidity | Lower coating demand, longer service life |

| Very good weldability | Common MIG/TIG welding; robust joint behavior | Faster fabrication, fewer defects |

| Good formability | Suitable for bending, rolling, and pressing | Ideal for panels, enclosures, shaped components |

| Moderate strength with high ductility | Better durability under vibration and minor impact | Transport and vehicle body parts |

| Attractive surface finishing | Takes paint well; uniform appearance | Good cosmetic finish for exposed panels |

| Low density | Lightweight structures | Reduced fuel use and easier handling |

Typical Applications

| Industry | Common uses | Why 5754 H11/H111 is selected |

|---|---|---|

| Marine | Deck plates, gangways, hull-related components, tanks, covers | Seawater/atmospheric corrosion resistance, weld-friendly |

| Transportation | Truck bodies, trailers, bus panels, rail interior/exterior panels | Formability + strength balance, weight savings |

| Automotive | Underbody shields, structural panels, battery trays (by design) | Corrosion resistance, stamping and joining capability |

| Chemical and food handling | Storage tanks, walkways, covers, non-pressurized vessels | Resistance to many corrosive environments |

| General fabrication | Machine bases, jigs, tooling plates, guards | Workability and consistent supply |

Chemical Composition (Typical Limits, wt.%)

Composition may vary slightly by standard (EN/ASTM equivalents), but 5754 chemistry is tightly controlled around magnesium content and impurity limits.

| Element | Mg | Mn | Cr | Si | Fe | Cu | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 5754 (typical limits) | 2.6–3.6 | ≤0.50 | ≤0.30 | ≤0.40 | ≤0.40 | ≤0.10 | ≤0.20 | ≤0.15 | Balance |

Why chemistry matters

- Mg drives corrosion resistance and strength through solid-solution strengthening.

- Low Cu supports superior corrosion performance compared with copper-bearing alloys.

- Controlled Fe/Si helps maintain ductility and surface quality.

Mechanical Properties (Typical at Room Temperature)

Actual values depend on plate thickness, production route, and specification. The table below reflects common ranges used in purchasing and design discussions for H11/H111 plates.

| Property | Unit | 5754-H111 (typical) | 5754-H11 (typical) |

|---|---|---|---|

| Tensile strength (Rm) | MPa | 190–240 | 210–260 |

| Yield strength (Rp0.2) | MPa | 70–120 | 90–140 |

| Elongation (A50) | % | 12–22 | 10–18 |

| Brinell hardness (HBW) | - | 55–70 | 60–80 |

Selection tip

- Choose H111 when forming is a priority and maximum ductility is desired.

- Choose H11 when slightly higher strength and dent resistance are preferred without sacrificing easy fabrication.

Physical Properties (Reference Values)

| Property | Unit | Typical value |

|---|---|---|

| Density | g/cm³ | 2.66 |

| Elastic modulus | GPa | 69–70 |

| Thermal conductivity | W/m·K | 130–150 |

| Electrical conductivity | %IACS | 28–34 |

| Coefficient of thermal expansion | µm/m·K | 23–24 (at ~20–100°C) |

| Melting range | °C | ~600–650 |

These values help with weight estimation, thermal design, and dimensional tolerance considerations in fabricated assemblies.

Plate Technical Specifications (Supply Range)

Supply ranges vary by mill capability. The table below reflects typical commercial offerings for aluminum plate.

| Item | Typical offering |

|---|---|

| Product form | Aluminium plate (hot rolled or precision plate, depending on requirement) |

| Temper | H11, H111 |

| Thickness range | 3–150 mm (common), thicker on request |

| Width range | Up to ~2000 mm common (wider on request) |

| Length range | Up to ~6000 mm common (custom cut available) |

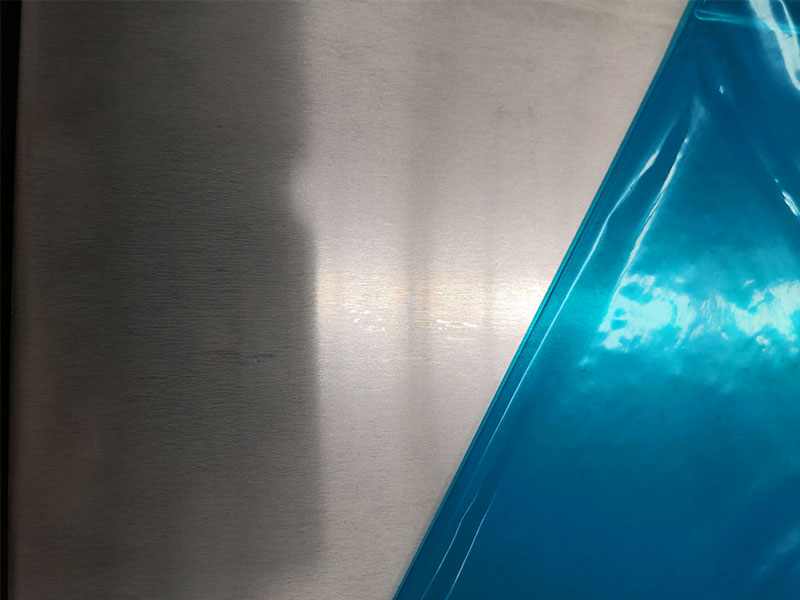

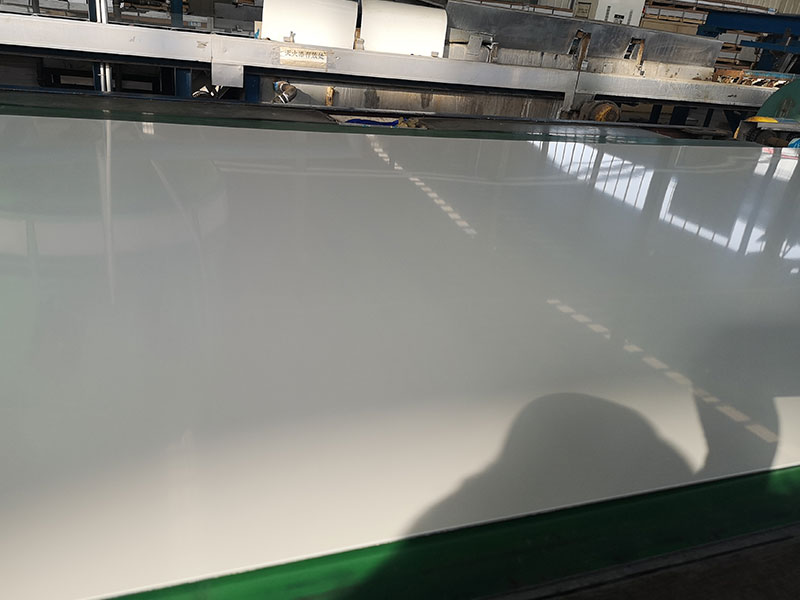

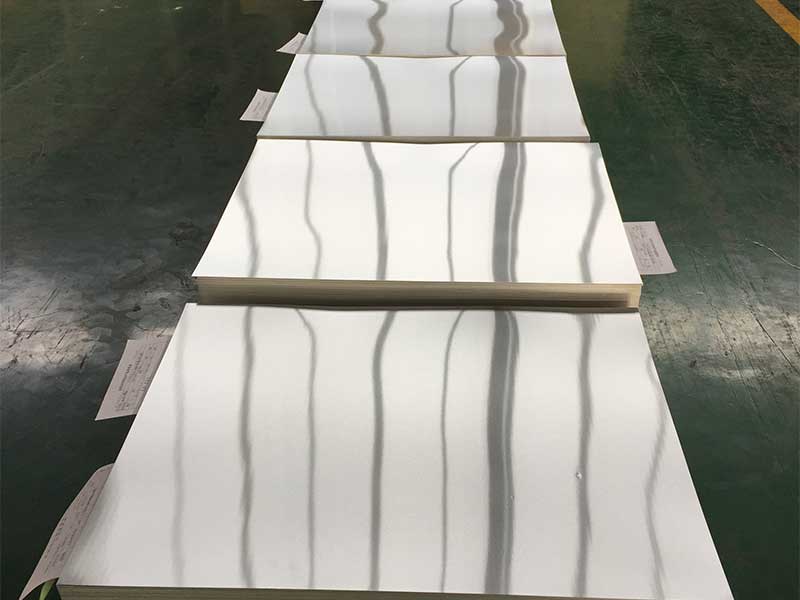

| Surface | Mill finish, brushed, PVC protected, or customer-specified |

| Flatness control | Standard commercial or improved flatness by agreement |

| Standards (common references) | EN 485 / EN 573, ASTM B209 (equivalent product families) |

| Documentation | Mill test certificate, chemical and mechanical report |

Fabrication and Processing Notes

| Process | Performance of 5754 H11/H111 plate | Practical guidance |

|---|---|---|

| Welding | Excellent | Common filler choices include 5xxx fillers selected for strength/corrosion needs; control heat input to limit distortion |

| Forming | Very good | Larger bend radii are safer for thick plate; H111 offers extra forming margin |

| Machining | Good | Use sharp tooling; manage chip evacuation; use coolant for improved finish |

| Cutting | Good | Works well with saw, waterjet, and plasma/laser (by thickness); deburr for best edge quality |

| Surface finishing | Very good | Paint and protective coatings adhere well; anodizing is possible with a uniform industrial appearance |

Corrosion Resistance and Service Environment

5754 is widely regarded as a strong performer in marine atmosphere and many industrial environments. Its low copper content supports resistance to general corrosion, and its magnesium content provides robust behavior in chloride-containing environments typical of coastal exposure. For long-term aesthetics, customers often use powder coating or marine-grade paint systems; for maximum durability in aggressive conditions, attention to crevice design, drainage, and galvanic isolation remains essential.

| Environment | Typical behavior | Design note |

|---|---|---|

| Marine atmosphere | Excellent | Avoid stagnant crevices; isolate dissimilar metals |

| Industrial humidity | Excellent | Good for enclosures and housings |

| Mild chemicals | Generally good | Confirm compatibility for specific chemicals |

| Galvanic contact | Needs care | Use isolators when joining to steel/copper alloys |

Ordering Guidance (What to Specify)

To receive consistent material for fabrication, purchase specifications should clearly define plate condition and inspection needs.

| Ordering item | Recommended detail |

|---|---|

| Alloy & temper | 5754-H11 or 5754-H111 |

| Dimensions | Thickness × width × length; tolerances if critical |

| Standard | EN or ASTM reference aligned to your market |

| Surface | Mill finish / protective film / cosmetic requirement |

| Certification | MTC with heat number traceability |

| Additional requirements | Flatness, ultrasonic testing, grain direction marking, special packing |

Alloy 5754 Temper H11 H111 aluminium plate is a corrosion-resistant, weldable, and highly formable 5xxx-series Al-Mg plate widely used in marine, transportation, and general fabrication. With reliable mechanical properties, lightweight performance, and excellent surface finishing capability, 5754-H11 offers slightly higher strength while 5754-H111 provides extra ductility for forming. Available in a broad thickness range with mill certification, 5754 H11/H111 plate is an efficient choice for durable welded structures, vehicle panels, and marine-exposed components requiring long service life and consistent quality.

https://www.aluminumplate.net/a/alloy-5754-temper-h11-h111-aluminium-plate.html