1060 H18 Aluminum Sheet Perforated

the Utility and Versatility of 1060 H18 Aluminum Sheet Perforated

In the landscape of materials science, aluminum alloys consistently emerge as strong contenders due to their remarkable combination of lightness, durability, and malleability. Among these, the 1060 H18 aluminum sheet perforated serves as a remarkable example of engineering excellence and practical applicability. To delve deeper into the nuances of this alloy and its perforated variants, we must adopt a unique lens: examining its relevance in modern design and functionality across industries.

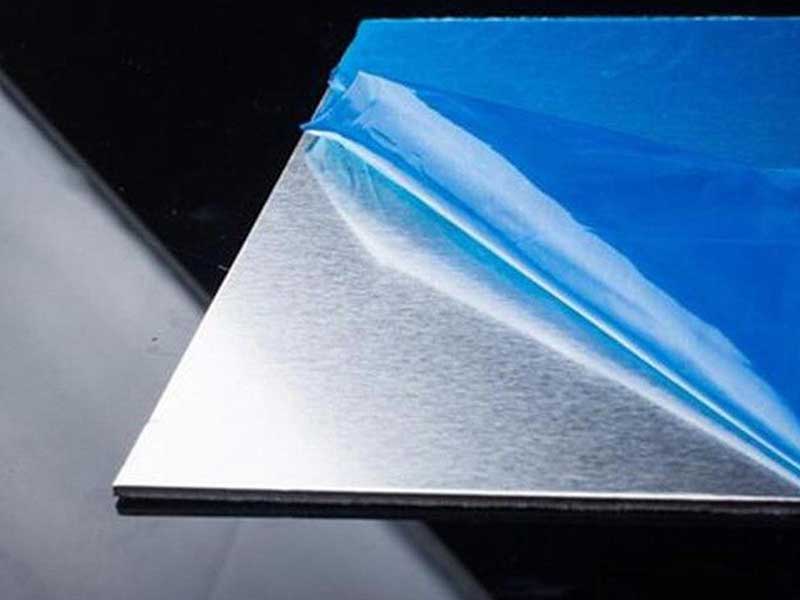

Working with 1060 H18 aluminum sheet for perforation presents a unique set of considerations. Its inherent softness (H18 temper) makes it relatively easy to pierce, leading to higher production speeds and lower tooling wear compared to harder tempers. However, this softness also necessitates careful handling to avoid deformation during the perforation process itself. We've found that optimized clamping pressure and precise tooling geometry are crucial to maintaining consistent hole size and pattern across the entire sheet. Furthermore, the 1060 alloy's excellent formability allows for more intricate perforation designs, opening up possibilities for bespoke customer orders that demand complex patterns or smaller hole sizes than would be feasible with harder alloys. This has been particularly advantageous in securing contracts for decorative architectural panels.

A recurring challenge with 1060 H18 is its susceptibility to burring during perforation. Minimizing burr formation requires meticulous attention to the perforation method – whether it's punching, laser cutting, or chemical etching – and subsequent deburring processes. We've experimented with various techniques, including specialized tooling with sharp edges, optimized cutting parameters (for laser cutting), and post-perforation brushing or vibratory finishing, to achieve the required surface finish and prevent burrs from compromising the final product's quality or causing issues in downstream applications. Careful selection of lubricants during perforation also helps minimize burr formation and tooling wear. Finding the optimal balance between speed, hole quality,

1060 H18 Aluminum

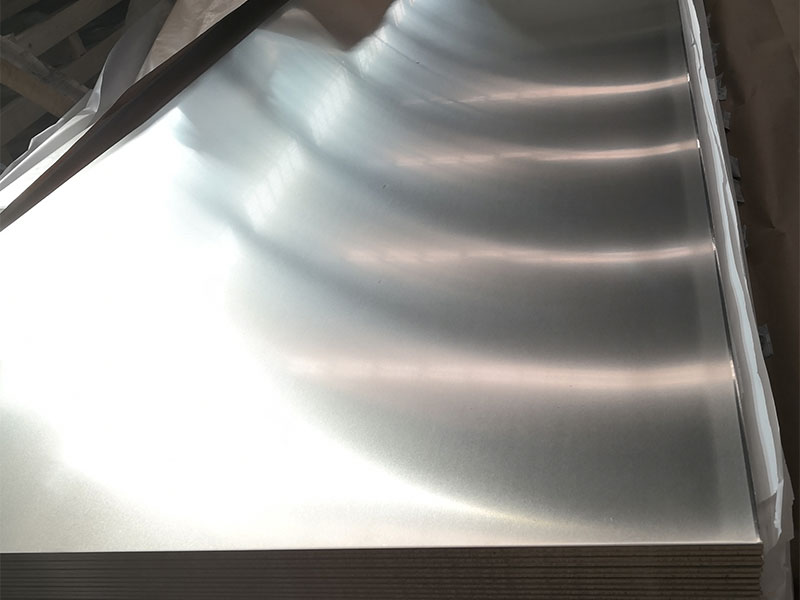

For many, aluminum's popularity may be rooted in its innate properties, such as high corrosion resistance and excellent thermal conductivity. The 1060 alloy, with its high purity (99.6% minimum aluminum content), epitomizes these attributes. The "H18" temper designation, commonly understood as work-hardened, ensures that the material achieves a high strength level without significantly sacrificing tensile properties. This makes it an ideal candidate for a range of applications where both strength and lightweight characteristics are essentials.

What distinguishes the 1060 H18 variant from other aluminum alloys is its exceptional ductility and the ease of forming into sheets. This property presents an array of opportunities for creative solutions across various industries—from architecture to food processing—especially when we incorporate perforation into the design.

The Magic of Perforation

At its core, perforation is a transformative process that converts solid metal sheets into versatile, airy structures. By introducing holes and patterns into a 1060 H18 aluminum sheet, manufacturers imbue the material with not only aesthetic appeal but also functional diversity.

The primary motivation for perforated aluminum is to achieve an optimal blend of lightweight strength while mitigating the density typically observed in solid sheets. This creates significant utilities beyond mere weight saving.

Airflow and Ventilation: In fields such as HVAC and industrial design, perforated 1060 H18 sheets are applied in ventilation grids and diffusers due to their ability to facilitate air circulation. The perforations maintain structural integrity while optimizing airflow, resulting in enhanced environmental efficiency.

Aesthetic Appeal: Filigree patterns in architectural panels or internal design elements foster visual interest, providing a modern ethereal touch. Unlike solid sheets, which serve functional purposes, perforated panels give a depth of character that can influence mood and attract gaze, capturing the essence of a space.

Weight Considerations for Transportation: In transportation sectors—be it automotive or aviation—the inclusion of perforated aluminum panels aids in reducing vehicle mass while retaining necessary protective functions. This is integral in meeting industry regulations without compromising safety or efficiency.

Reflecting Sustainability

As design aesthetics and functionality converge, sustainability remains paramount in the conversation about modern materials. The 1060 H18 aluminum sheet, particularly in perforated form, showcases the principles of sustainable manufacturing. Aluminum is infinitely recyclable, maintaining its inherently strong attributes even after numerous lifecycles. The perforation process often minimizes metal wastage compared to more traditional machining, promoting environmentally responsible manufacturing policies.

Furthermore, lightweight materials contribute to energy savings throughout the lifecycle of use. Aircraft and vehicles benefit from reduced fuel consumption thanks to their design underpinned by materials as efficient as perforated 1060 H18 sheets.

Closing Thoughts

The mastery behind the 1060 H18 aluminum sheet perforated transcends traditional industrial narratives; it tells a story enriched with complexity, indigenous craftsmanship, and sustainability. Acknowledging its multiple roles—from building airflow systems, enriching architectural aesthetics to enabling lower carbon footprints demonstrates its transformational capabilities.

As contemporary industries confront challenges around efficiency, design flexibility, and environmental accountability, embracing innovations embodied by perforated aluminum alloys like 1060 H18 opens pathways to enduring solutions. Thus, as specifications are contemplated and products developed, let this exemplary material reveal new realms of cost-effectiveness and functional performance, firmly rooting its importance not just in construction but in the essence of innovative design principles that shape our world today.

https://www.aluminumplate.net/a/1060-h18-aluminum-sheet-perforated.html