2024 Forged Alloy Aluminum Sheet

When approaching the world of aluminum alloys, particularly when discussing 2024 forged alloy aluminum sheets, it is essential to understand not only their mechanical properties and applications but also the dreams that they embody in the realms of innovation and efficiency. This distinctive view embraces 2024 aluminum not just as a material but as a cornerstone of performance in industries where weight, strength, and durability are of the utmost importance.

The Unique Composition of 2024 Aluminum Alloy

The distinctive composition of 2024 alloy presents a mélange of attributes. It primarily consists of 90% aluminum, complemented by a precise mix of copper, which exudes exceptional strength-to-weight ratios—often preferred in the aerospace sector. However, what truly sets it apart isn’t merely its chemical make-up; it’s the alchemy of application it promises.

Working with 2024 forged alloy aluminum sheet presents a unique set of challenges and advantages compared to other aluminum alloys. Its high strength-to-weight ratio is a significant selling point, making it ideal for aerospace applications and high-performance components where weight reduction is paramount. However, this strength comes at the cost of increased formability challenges. We often see issues with cracking during forming operations, especially when dealing with intricate geometries or aggressive bending radii. Proper heat treatment is crucial; inconsistencies can lead to significant variations in mechanical properties across the sheet, resulting in rejects and potential in-service failures. Careful control of the forging process itself, including temperature and pressure, directly impacts the final product’s microstructure and consequently its strength and ductility.

Furthermore, the machinability of 2024 forged aluminum sheet isn't as straightforward as some other alloys. The higher strength means increased tool wear and necessitates the use of specialized cutting tools and parameters to prevent tearing or chipping. Surface finish is another concern; achieving a consistently smooth surface requires considerable skill and attention to detail during both the forging and subsequent machining stages. We've found that implementing rigorous quality control measures throughout the entire production process, from raw material inspection to final surface finish verification, is absolutely critical for producing high-quality 2024 forged aluminum sheets that meet the stringent demands of our customers. Investing in advanced inspection technologies and well-trained personnel is vital to minimizing waste and ensuring

An All-Stars Material in Aerospace Engineering

It is suspending disbelief to think that the spacecraft and jets cruising our skies were built using this very alloy. The 2024 forged alloy aluminum sheet is celebrated for its high fatigue resistance, especially at subzero temperatures. These captivating qualities have made it the go-to material for the aerospace community, expectations of performance override the conventional bounds of material science, ushering in an era of efficiency.

Distinctively Sustainable: Recyclability

As we wrestle with global challenges such as climate change and resource availability, the expressiveness of 2024 alloy showcases its robust recyclable nature. Nearly all aluminum—over 75%—produced to date resides in circulation, reincarnating over and over. Partner this with the efficient production forward represented through 2024 materials that can lead to retained mechanical properties after recycling, viewers can reflect upon a sustainable transformation amidst systematic innovation.

Heat-Treating: An Artisan Craft

Taking the uniqueness a step further, the heat-treating process imparted to 2024 alloys is more an artisan craft than a mere manufacturing process. The care taken at this step is an acknowledgement that engineering is not merely about developing squares and weight tolerances; it represents a collaborative dance between materials and methods, carefully tuned to achieve balance and performance that sways—from soft to extremely hard upon dictation! Blending technique and theory cultivates a resilience that mundane aluminum alloys cannot hope to attain.

A Suggestion for the Everyday User: The Forging Influence

One of the often-overlooked characteristics of the forged process is its influence on the marginally perceptible characteristics, for example, grain structure. Within the forging transformation of 2024 aluminum sheets, the continuous alignment of molecular pathways fuses unique ductility and malleability with hopeful imperviousness. This honed material heaven supports not just aerospace yet every industrious venture—from lightning-fast automotive frames to hydro-systems utilized in steering and performance showcases. A crafted approach means customers sign off not just with results but also a reliable and resonating endorsement in quality.

Depth in Curating Finishes

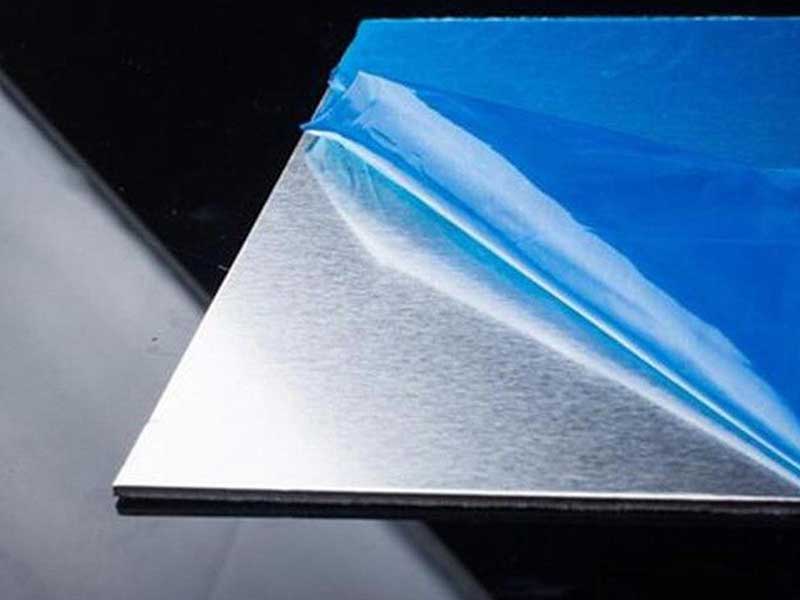

A spotlight on finish treatments reiterates the dreamy adaptability of aluminum. Clients can alter various parameters, and by choosing specific finishes, the look can shift fluidly from raw gleaming metallic allure to textured or anodized surfaces, catering to aesthetic values as much as utilitarian needs. Finding virtue in versatility charms designers offering enhanced flexibility, immersion into diverse environments all while streamlining the expectations on maintenance.

Shifting the conversations to the economic axes, it is necessary to address how 2024 forged alloy aluminum sheets carve their niches through longer-life spans, reduced weights promising lower-cost transportation, and minimal maintenance expenses compared to traditional stainless counterparts. Cutting down on transformative journeys preceding a panel—one sees markets miserably populate that lone connection ends up being governed by informed material choice, executing trends arduous and historical juxtaposition finds purchase in a mechanistic voice.

https://www.aluminumplate.net/a/2024-forged-alloy-aluminum-sheet.html