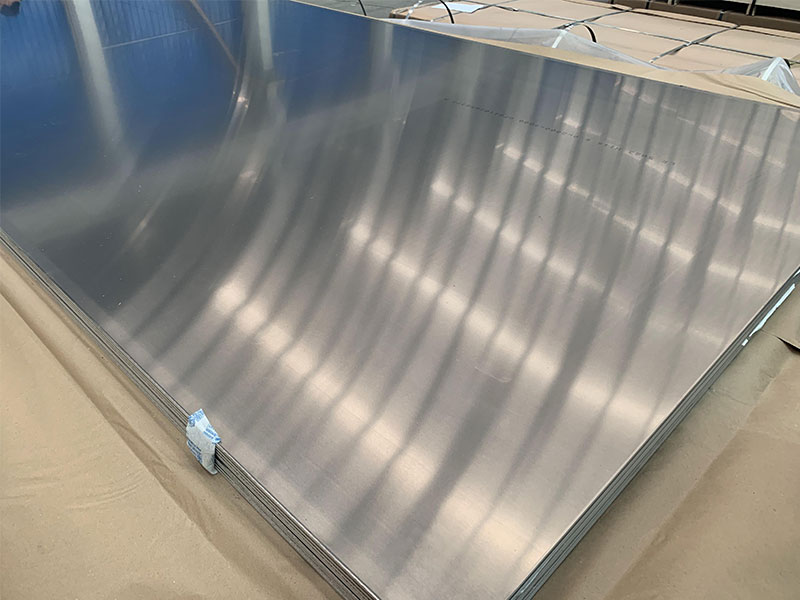

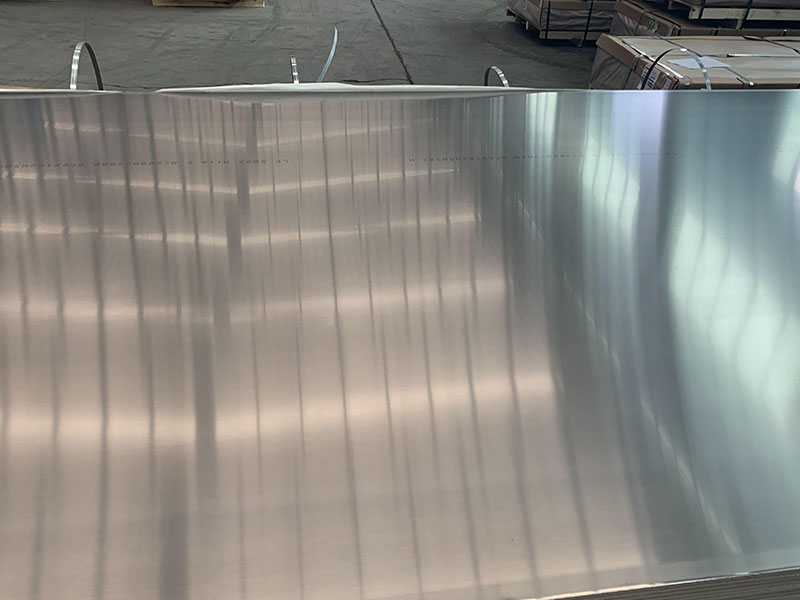

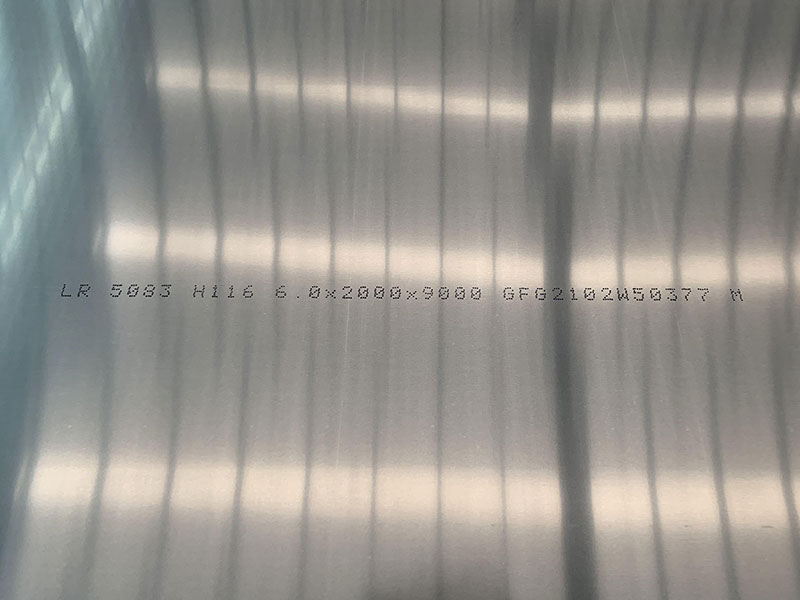

Marine grade aluminum plate 5083 h116

Marine Grade Aluminum Plate 5083 H116 is a high-performance aluminum alloy widely recognized for its outstanding corrosion resistance, exceptional strength, and excellent weldability, making it the material of choice for demanding marine environments. Engineered specifically for applications exposed to seawater and industrial atmospheres, this alloy meets the stringent requirements of shipbuilding, offshore platforms, naval vessels, and other marine structures.

The alloy 5083 belongs to the 5xxx series platform of aluminum-magnesium alloys. Aluminum 5083 comprises near 4.5% magnesium, with trace amounts of manganese and chromium providing structural enhancement. The H116 temper designation applies specific strain hardening methods followed by stabilization that improves stress corrosion resistance, essential where the plate is subjected to pounding and static loading commonly experienced in marine conditions.

Chemical Composition

| Element | Content (%) |

|---|---|

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Aluminum (Al) | Balance |

Note: These contents are per the ASTM B908/A480 specifications and vary slightly depending on the producer.

Mechanical Properties

| Property | Value (Metric Units) | Value (Imperial Units) |

|---|---|---|

| Tensile Strength (Rm) | 305 - 350 MPa | 44,000 - 50,700 psi |

| Yield Strength (Rp0.2) | ≥ 215 MPa | ≥ 31,200 psi |

| Elongation at break | ≥ 12 % | ≥ 12 % |

| Hardness (Brinell HB) | 75 - 95 | -- |

| Density | 2.66 g/cm³ | 0.096 lb/in³ |

The 5083-H116 aluminum plates exhibit excellent toughness and sustained strength at low temperatures, to around -195°C, providing crucial resistance against brittle failure due to cold marine environments.

Temper Designation: H116

The "H116" designation for aluminum 5083 signifies a strain-hardened state with subsequent stabilization to optimize stress corrosion cracking resistance. It is typically applied after hardening the metal plate through cold work processes such as rolling.

- H1xx Classification: Strand-hardened and naturally aged.

- "16" Treatment: Indicates modified strain hardening and process accepting a tested minimization of residual stress to resist seawater stress corrosion effects.

H116 aluminium plate has proven resilience against intergranular corrosion encountered on welded marine structure areas, maintaining overall structural integrity.

Compliance & Standards

Marine Aluminum 5083 H116 Plates are manufactured and tested in compliance with:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- ASME SB-928: Specification for Aluminum Marine Plate

- ABS (American Bureau of Shipping)

- DNV-GL (Det Norske Veritas - Germanischer Lloyd)

- ISO 209-2: Specification and supply conditions

These certifications ensure the plates meet the rigorous criteria demanded for marine and oceanographic engineering.

Application Highlights

- Shipbuilding: Hull plating, decks, bulkheads, and superstructures where durability and anti-corrosion are critical.

- Boat Manufacture: Motor yachts, sailboats, workboats requiring lightweight but strong structural elements.

- Ports & Marine Structures: Piers, offshore platforms, barges for unmatched seawater resistance.

- Defense Vessels: Patrol boats, landing crafts, naval structures demanding fatigue resistance.

- Cryogenic Tanks & Containers: Owing to low-temperature performance.

Advantages of Using 5083 H116 Marine Grade Plate

- Exceptional resistance to seawater corrosion and salt spray

- Excellent weldability without loss of strength

- High strength-to-weight ratio, contributing to fuel efficiency

- Superior performance under cyclic stress, enabling longevity

- Good formability suitable for complex marine shapes and weld joints

- Non-magnetic and good damping properties for noise reduction on vessels

Storage and Handling Guidelines

To maintain the integrity of the 5083 H116 marine aluminum plate, observe the following practices:

- Store in dry clean environments protected from direct humidity exposure

- Avoid stacking that could deform or scratch the plate surfaces

- Use non-ferrous or coated slings in handling to avoid metallic contamination

- Inspect for surface damage post shipping during onboarding construction activities.

https://www.aluminumplate.net/a/marine-grade-aluminum-plate-5083-h116.html