3 bars aluminium stucco embossed sheet h16

When it comes to combining aesthetic appeal with functionality in metal sheets, the “3 bars aluminium stucco embossed sheet H16” stands out as an exceptional choice. This material, far beyond being just another metal sheet, speaks to engineers, architects, and craftsmen who demand durability, texture, and precision in one package.

the Basics: What is a 3 Bars Aluminium Stucco Embossed Sheet?

First, l

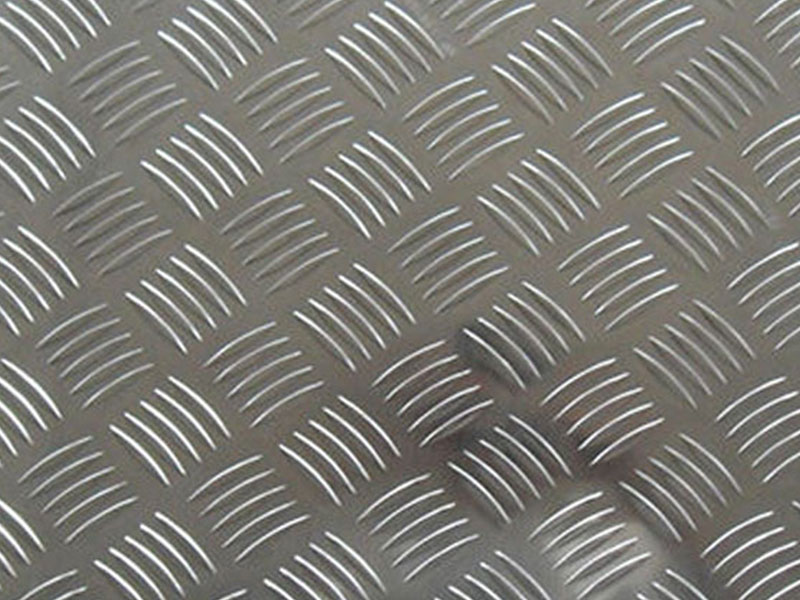

- 3 Bars: This refers to the embossed pattern consisting of three longitudinal raised bars repeatedly pressed into the sheet’s surface.

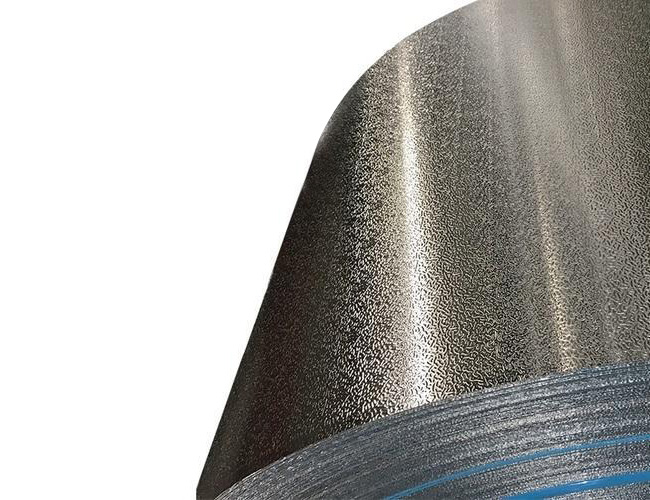

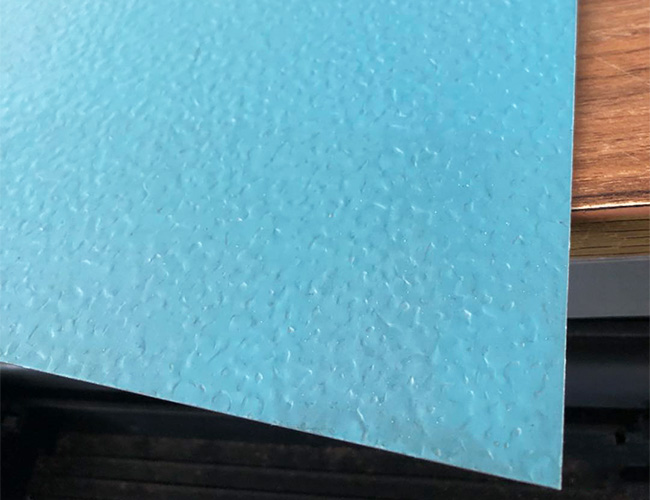

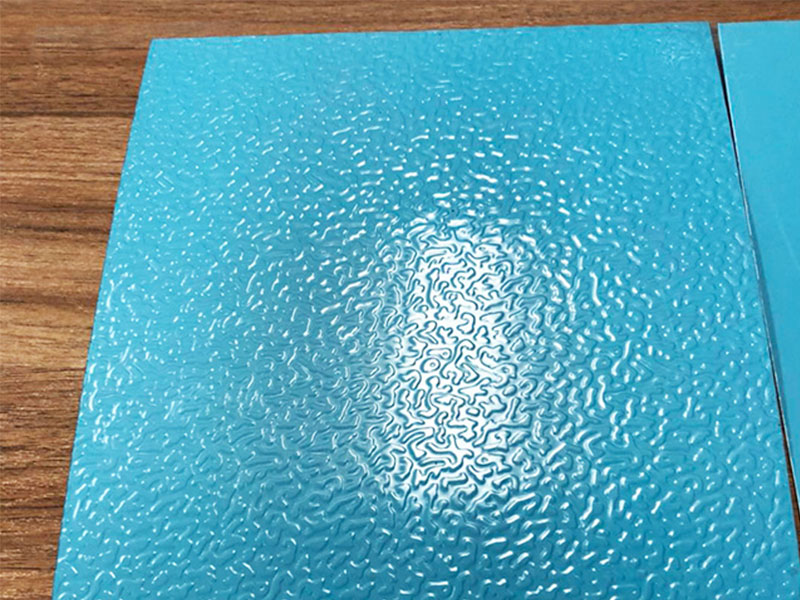

- Aluminium Stucco Embossed: 'Stucco' embossing provides a textured raised pattern on the surface. It was inspired by traditional stucco plaster’s rough texture but reimagined in aluminum form. Evolving from flat sheets, embossing enhances grip, slip resistance, and adds visual distinctiveness.

- H16 Temper: In aluminum temper designation, H16 means the sheet is strain hardened and partially annealed. This temper balances strength and formability, yielding a moderate tensile strength while ensuring the metal is workable.

Chemical Composition & Standards of the Aluminium Alloy

Typically, these embossed sheets use the 3000 series aluminum alloys, widely recognized for excellent corrosion resistance and good strength. One standard example is the 3005 alloy, commonly chosen for stucco embossed applications.

| Element | Typical Composition (%) |

|---|---|

| Aluminum (Al) | Balance |

| Manganese (Mn) | 0.5 – 1.0 |

| Iron (Fe) | ≤ 0.7 |

| Silicon (Si) | ≤ 0.6 |

| Copper (Cu) | ≤ 0.2 |

| Zinc (Zn) | ≤ 0.1 |

| Others | ≤ 0.05 |

Mechanical & Temper Properties for H16

| Property | Typical Value | Standard |

|---|---|---|

| Tensile Strength | 190 – 230 MPa | ASTM B209, EN 485-2 |

| Yield Strength | ~110 – 140 MPa | |

| Elongation (%) | 6 – 10 % | |

| Hardness (Brinell) | ~40 HB | |

| Temper | H16 – Strain Hardened, Partially Annealed |

The H16 temper is often seen as a “sweet spot” because it avoids brittleness while delivering a higher strength compared to softer tempers like O (annealed).

Advantages of 3 Bars Albanium Stucco Embossed Sheet H16

- Anti-slip Characteristics: The three raised, parallel bars combined with stucco embossing gives the sheet superior grip. This is a feature in flooring applications, ramps, walkways, and industrial truck beds where safety is critical.

- Enhanced Rigidity Without Weight Penalty: The embossing adds localized thickness and stiffness, reducing sheet flexing under load — something flat sheets struggle with — while keeping the weight advantage of aluminum.

- Corrosion Resistance: Thanks to the 3xxx series’ excellent natural corrosion resistance, these sheets perform well in outdoor environments and humid atmospheres.

- Noise & Vibration Dampening: The embossed texture interrupts sound waves and dampens vibrations, a benefit for transportation and architectural panels.

- Visual Distinctiveness: The 3-bar pattern exudes industrial robustness and texture, striking a balance between utility and style suitable for interior and exterior design accents.

Implementation Standards & Fabrication Guidelines

- Standards: Suppliers usually adhere to ASTM B209 / EN 485-2 specifications ensuring consistent chemistry and mechanical properties. B209 covers aluminum and aluminum-alloy sheet and plate specifications.

- Sheet Thickness Range: Generally between 0.6 mm to 3.0 mm, adjustable for specific project requirements.

- Width & Length: Roll widths commonly between 1000 – 1500 mm, cut-to-length sheets on client demand.

- Welding: The H16 alum sheet performs well with TIG and MIG welding methods due to its strain-hardened state; preheating usually unnecessary.

- Formability: Moderate cold forming capabilities — bending, stamping — but better springback control due to the partial annealing.

- Surface Treatments: Anodizing or PVDF coatings can extend corrosion resistance and color stability for architectural uses.

Consider the visionary warehouse architect who wants floors or wall panels that communicate “robust resilience” visually and tactilely — the three bars running in parallel, complemented by stucco embossing, symbolize linear strength and service durability. In transit industries, where every pound counts, replacing older checker plates with 3 bars embossed aluminum sheets saves weight, improving fuel efficiency and reducing operator fatigue from vibrations, while maintaining safety.

On an artistic level, reflective surfaces interplay with light differently beneath embossed areas, creating subtly changing patterns emphasizing motion and structure. This makes the sheets highly attractive for lobby floors, exhibition stands, or luxury vehicle interiors.

https://www.aluminumplate.net/a/3-bars-aluminium-stucco-embossed-sheet-h16.html