3003 Color Coated Aluminium Plate

The 3003 color coated aluminum plate stands out in the world of modern materials, combining distinctive aesthetic properties with outstanding functionality. This particular alloy, belonging to the 3000 series, is primarily recognized for its excellent workability, corrosion resistance, and myriad applications across various industries. the technical specifications and nuances of 3003 color coated aluminum is essential for leveraging its capabilities effectively.

What is 3003 Color Coated Aluminum Plate?

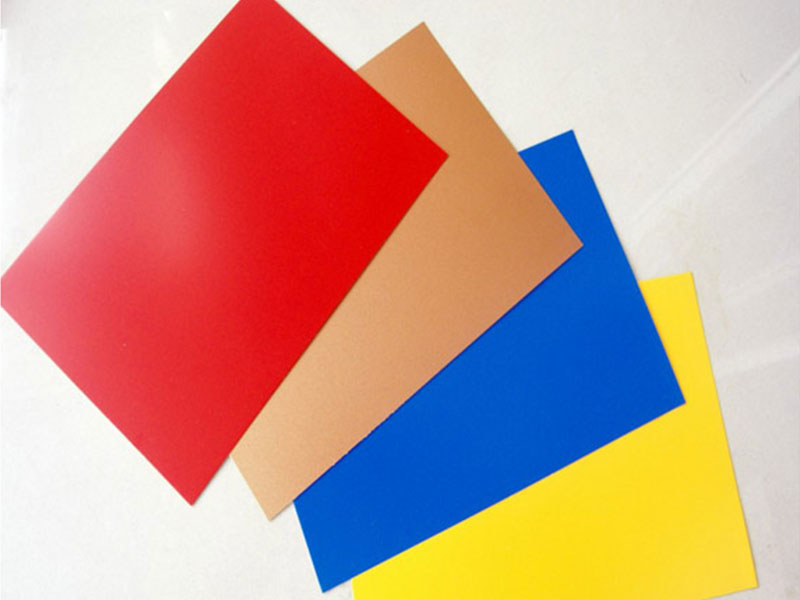

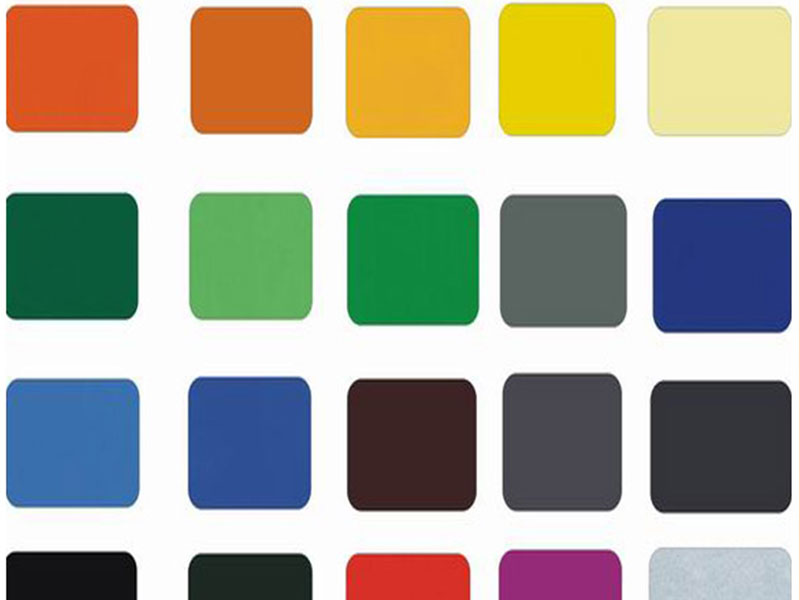

The 3003 aluminum alloy is known for its moderate strength and excellent resistance to corrosion. This alloy is invigorated by a protective coating that not only enhances its visual appeal but also amplifies its durability. The coating system is typically composed of a base layer of paint(s) that is baked for optimal adhesion and finish. The versatility in available colors and finishes means that the 3003 color coated aluminum plate can satisfy stringent aesthetic demands in diverse projects.

Properties of 3003 Aluminum Alloy

- Aluminum Content: Approximately 97.5% to 99% pure aluminum

- Density: Worlds around 2.73 g/cm³

- Yield Strength: Around 138 MPa

- Tensile Strength: Approximately 210 MPa

- Elongation: Around 20% in 50 mm

- Corrosion Resistance: Excellent, especially against atmospheric conditions and chemicals.

Chemical Compositions

| Element | Percent (%) |

|---|---|

| Aluminum | 97.5 - 99.0 |

| Manganese | 1.0 - 1.5 |

| Copper | 0.1 max |

| Magnesium | 0.1 max |

| Silicon | 0.5 max |

| Other | 0.3 max |

Tempering

The tempering condition of the 3003 series is typically O, H14, H24, and H34. Each classification is unique in physical characteristics.

- O (Annealed): Offers enhanced workability which suits manufacturing needs.

- H14 (Work Hardened): Increased strength as a result of improved hardness; suitable for structural applications.

- H24 (Work Hardened): Superior strength settings combined with equal elongation properties; ideal for demanding applications.

- H34 (Work Hardened and Strain Hardened): High tensile strength and consistent surface structure, marching well with construction-type uses.

Applications of 3003 Color Coated Aluminum Plates

The multifunctionality of 3003 color coated aluminum plates allows them to be utilized across a variety of perspectives:

Architectural and Construction Components: We frequently see these plates in façades, roofs, and building cladding. The assortment of colors provides not only aesthetic versatility but also enables weather resistance. Modern architecture increasingly relies on aluminum sheets for both functional and attractive designs.

Disposable Containers: Many food service businesses and companies produce take-out dishes and tins which remain lightweight yet reliable, preserving safety standards concerning resistance to heat.

Appliances and Equipment: Since surfaces often undergo wear in household appliances, aluminum plates coated for color enable an element of protective covering while fortifying function in furniture, refrigerators, ovens, and microwaves.

Electrical Applications: Another facet exciting engineers is in various electronic housing and sensitive appliance circuits that benefit from 3003 sheets' conductivity without the worry of corrosion or wear.

Signage: Street signs and other outdoor membranes leverage the longevity of aluminum combined with its color coatings for stunning, long-lasting graphics; an ideal match when function supports communication.

Automotive Applications: Weight reductions and highly durable surfaces are pivotal within vehicle heritages—it delivers optimal oxidation avoidance under demanding conditions.

Implementation Standards

When looking at the industry standards and certifications associated with the manufacturing and application of 3003 color-coated aluminum plates, benchmarks include:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- EN 573-3: Aluminum and Aluminum Alloys—Chemical Composition

- AS/NZS 8257: Quality Assurance standards for batch manufacturing standards

- ISO 9001: General standard projecting stringent manufacturing guidelines—the essence of reliable evaluation in quality framed products.

https://www.aluminumplate.net/a/3003-color-coated-aluminium-plate.html