Embossed aluminum sheet 1mm 5mm 6 Mm 8mm 15mm

If smooth aluminum sheet feels like a blank page, embossed aluminum feels like handwriting: it carries texture, grip, direction, and intent. People often shop embossed sheet by thickness first-1mm for light skins, 5mm and 6mm for robust panels, 8mm for hard-wearing decks, 15mm for serious structural confidence. But thickness alone doesn't explain why embossed aluminum works so well in the messy real world where shoes are wet, cargo shifts, forklifts scrape, salt drifts in from the coast, and cleaning crews use chemicals that don't read the label.

A more useful way to look at embossed aluminum sheet is to treat it as a "surface engineering" product that happens to be metal. The emboss pattern is not decoration; it is a mechanical feature that changes friction, stiffness, wear behavior, and visual tolerance to dents and scratches. The thickness is the backbone that decides how much load the sheet can take, how it can be fabricated, and how long it stays flat.

What embossing actually does, beyond appearance

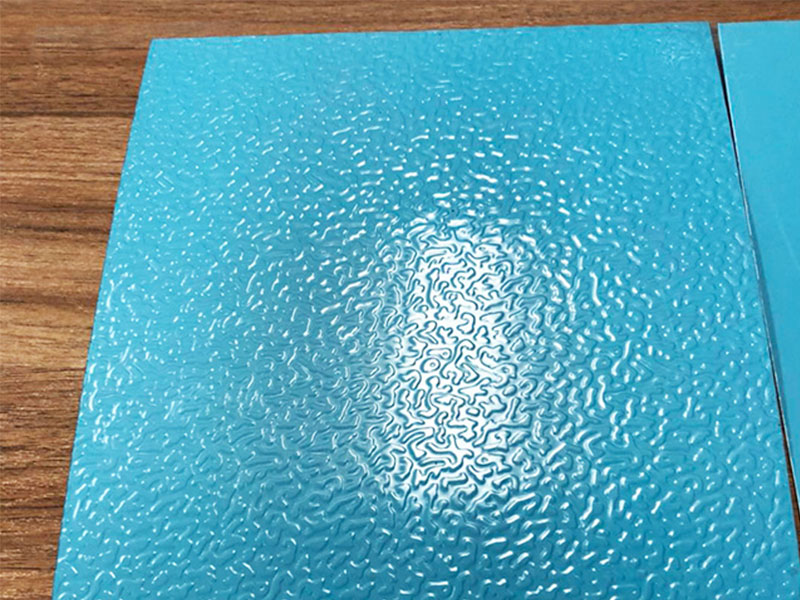

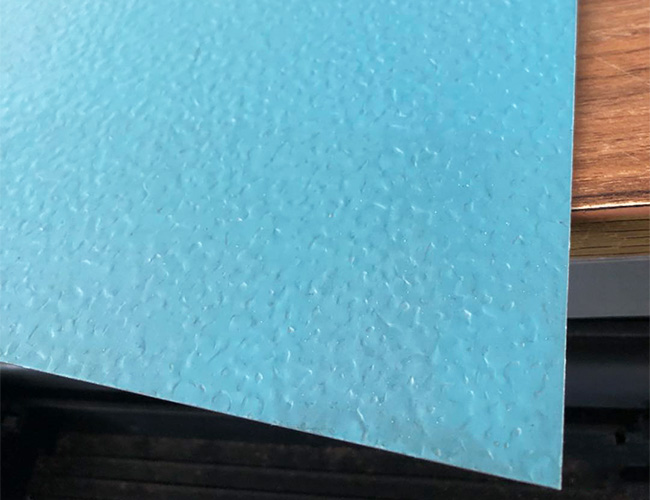

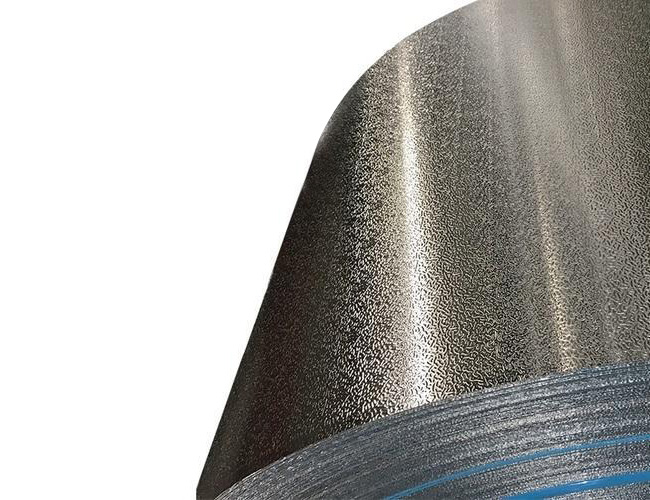

Embossing forms a raised pattern-diamond, five-bar (tread plate), orange peel, stucco, lentil, or custom textures-by rolling or stamping. This pattern adds localized geometry, and geometry is everything.

On thin sheet such as 1mm, embossing can noticeably increase apparent rigidity. A flat 1mm sheet can "oil-can" easily; an embossed 1mm sheet resists that flutter because the pattern breaks up long unsupported spans. On thicker gauges like 6mm or 8mm, the stiffness benefit is less dramatic because thickness already dominates bending stiffness, but the pattern still improves slip resistance and disguises surface damage. The raised features take the first contact, protecting the valleys from abrasion and making scuffs look like part of the texture.

Embossing also affects heat transfer contact area, paint wetting, and even how fingerprints show. In food trucks, elevator interiors, and industrial partitions, that matters as much as strength.

Choosing thickness with a fabricator's mindset

Thickness selection is usually described as "light, medium, heavy," but in practice you're choosing a fabrication route and a service life.

1mm embossed aluminum sheet is a skin material. It shines as wall cladding, interior panels, appliance shrouds, ceiling soffits, and decorative protection on doors and counters. It bends easily, can be cut with basic tools, and can be bonded or riveted without demanding heavy equipment. The tradeoff is dent resistance and fastener pull-through; you often pair it with a backing, frame, or substrate.

5mm and 6mm embossed aluminum sheet step into the zone where the sheet begins to act like a plate. These thicknesses are common for vehicle steps, access covers, small platforms, ramps for light trolleys, and industrial guarding. They can be welded, bolted, or used with countersunk fasteners depending on the pattern depth and required flushness. A 5–6mm tread plate is a practical compromise: stiff enough to feel solid underfoot, yet still manageable for cutting and handling.

8mm embossed aluminum sheet is chosen when deflection control becomes central: floors in service vehicles, heavy-duty walkways, offshore modules, and loading edges that see repeated impact. At 8mm, the sheet can tolerate more abuse before permanent deformation shows, and it is more forgiving if support spacing isn't perfect.

15mm embossed aluminum sheet is not a casual choice. It is heavy, expensive, and difficult to form-but it is sometimes the right answer for high point loads, long spans, or when you need a machined, durable plate with traction. Think heavy industrial platforms, bridge-like covers, or marine structures where corrosion resistance and weight savings over steel still matter, but you cannot compromise on stiffness. Many projects at this thickness also consider flat plate with applied anti-slip, yet embossed plate remains attractive because the traction is integral and does not peel.

Alloy and temper: the hidden half of the specification

Two sheets of the same thickness and pattern can behave completely differently depending on alloy and temper. For embossed sheet, you're balancing formability, corrosion resistance, weldability, and strength.

The most common families are 1xxx, 3xxx, 5xxx, and sometimes 6xxx.

- 1050/1060/1100 are very formable and corrosion resistant, excellent for decorative and chemical environments, but relatively low strength.

- 3003 (Al-Mn) is a classic for cladding and general fabrication: good formability, decent strength, good corrosion resistance.

- 5052/5754 (Al-Mg) are workhorses for marine and transport: higher strength, excellent corrosion resistance, good weldability.

- 6061/6082 (Al-Mg-Si) can be strong in T6, but embossed products are less commonly supplied in high-strength tempers because deep textures and tight forming may require softer states.

Temper matters as much as alloy. H14/H24 are common for embossed tread plate when you want moderate strength with workable forming. H32 on 5xxx gives a strong, stable sheet for marine and industrial service. O temper is the easiest to form but dents more easily.

Practical standards and implementation cues

Embossed aluminum tread plate is often supplied in line with commonly recognized specifications. Depending on market, you may see references such as ASTM B632 for aluminum tread plate, ASTM B209 for general aluminum sheet/plate, and EN 485 series for wrought aluminum sheets and plates in Europe. What matters on the purchase order is clarity: alloy, temper, thickness tolerance, pattern type, and whether thickness is measured including or excluding the raised pattern.

In practice, many suppliers quote "base thickness" and provide an approximate "overall thickness" including the pattern height. For anti-slip flooring, the raised height contributes to grip; for fit-up under door clearances, overall thickness is the reality. This is one of the most frequent causes of installation surprises, especially at 5mm, 6mm, and above.

For welding, 5xxx alloys are generally friendly, but tread patterns create valleys where contamination can hide. Good cleaning and weld prep are not optional. For bolting, consider wide washers or backing plates on thinner gauges like 1mm, and plan hole placement to avoid drilling through the peak of the emboss where a fastener may not seat properly.

Chemical behavior: what survives, what stains, what pits

Aluminum's natural oxide layer is robust, and embossing can actually help hide superficial staining, but chemical exposure is still a design input.

Acids and strong alkalis can attack aluminum aggressively. Chlorides (salt) can drive pitting, particularly in crevices where moisture stays. That is why 5xxx alloys are so widely used in marine and coastal environments. For cleaning, neutral pH detergents are safest; harsh alkaline cleaners can dull the surface and create patchy appearance, which looks worse on smooth sheet than on embossed-but still matters in architectural work.

When you expect contact with dissimilar metals, galvanic corrosion becomes real. Embossed sheet used as flooring often meets steel frames; isolate with coatings, gaskets, or non-conductive barriers where possible, especially in wet service.

Typical properties and chemical composition reference

Below is a practical reference for commonly used alloys for embossed aluminum sheet. Values are typical and can vary by producer and product thickness; always confirm with mill test certificates for compliance.

Typical mechanical properties (room temperature)

| Alloy | Common temper | Typical yield strength (MPa) | Typical tensile strength (MPa) | Typical elongation (%) |

|---|---|---|---|---|

| 1050 | H14 | 85–110 | 95–130 | 3–10 |

| 1100 | H14 | 75–105 | 90–125 | 4–12 |

| 3003 | H14 | 115–145 | 140–190 | 4–10 |

| 3003 | H24 | 130–160 | 160–205 | 4–10 |

| 5052 | H32 | 160–200 | 210–260 | 6–12 |

| 5754 | H22/H32 | 170–220 | 240–290 | 6–15 |

| 6061 | T6 | 240–280 | 290–330 | 8–12 |

Typical chemical composition (wt.%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | - | ≤0.05 | ≤0.03 | ≥99.50 |

| 1100 | ≤0.95 (Si+Fe) | - | 0.05–0.20 | ≤0.05 | - | - | ≤0.10 | ≤0.05 | ≥99.00 |

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | - | - | ≤0.10 | - | Bal. |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | - | Bal. |

| 5754 | ≤0.40 | ≤0.40 | ≤0.10 | ≤0.50 | 2.6–3.6 | ≤0.30 | ≤0.20 | ≤0.15 | Bal. |

| 6061 | 0.40–0.80 | ≤0.70 | 0.15–0.40 | ≤0.15 | 0.8–1.2 | 0.04–0.35 | ≤0.25 | ≤0.15 | Bal. |

A buyer's final check: the "three realities"

Embossed aluminum sheet succeeds when it matches three realities: the reality of feet and wheels (traction and wear), the reality of fabrication (cutting, bending, fastening, welding), and the reality of environment (salt, cleaners, dissimilar metals). Thickness choices like 1mm, 5mm, 6mm, 8mm, and 15mm are not just sizes; they are commitments to a certain kind of build.

If you want a light, resilient skin that forgives scratches, 1mm embossed sheet is a smart, economical canvas. If you want a platform that feels dependable every day, 5–6mm is the practical heartbeat of tread plate. If you need confidence under hard service, 8mm carries that weight. And if you are building something that cannot flex, cannot dent, and cannot become slippery even after years of abuse, 15mm embossed aluminum plate is less a sheet and more a statement of intent.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-1mm-5mm-6-mm-8mm-15mm.html