Aluminum matrix composites heat exchanger

Aluminum matrix composites (AMCs) heat exchangers combine the lightweight, formability, and corrosion resistance of aluminum with the enhanced stiffness, wear resistance, and thermal stability contributed by ceramic reinforcements. The result is a heat exchanger platform engineered for compact, high-flux thermal management where conventional aluminum can struggle with creep, erosion, or dimensional stability under aggressive duty cycles.

AMCs are especially attractive for air-to-liquid and liquid-to-liquid designs that demand thin walls, high fin density, and consistent performance over long service life. By tailoring reinforcement type and volume fraction, AMC heat exchanger components can be tuned for thermal conductivity, coefficient of thermal expansion (CTE), and mechanical strength-supporting tighter tolerances, higher operating pressures, and improved resistance to vibration and thermal cycling.

What It Is

An AMC heat exchanger uses an aluminum alloy matrix-commonly from the 3xxx, 5xxx, or 6xxx families-reinforced with particulates or short fibers such as silicon carbide (SiC), alumina (Al₂O₃), or graphite. The reinforcement is distributed through the matrix to create a composite that behaves differently from monolithic aluminum.

Typical constructions include:

- Brazed plate-fin cores with AMC header plates or side plates for stiffness and stability

- Microchannel (multiport) tubes where erosion resistance and creep resistance are required

- Liquid cold plates or baseplates for power electronics, where CTE control is critical

Features Customers Care About

| Feature | What it delivers | Why it matters in heat exchangers |

|---|---|---|

| High specific stiffness | Reduced deflection at low weight | Thin-wall designs stay dimensionally stable |

| Improved creep resistance | Better strength retention at elevated temperature | Helps in under-hood, aerospace, and high-duty cycling |

| Tailored CTE | Closer match to ceramics/semiconductors | Reduces thermal fatigue in electronics cooling |

| Good corrosion management | Aluminum's natural oxide + coatings | Long service life with proper inhibitor/coating selection |

| Manufacturability options | Extrusion, roll-bonding, machining, brazing variants | Allows scalable production and integration |

Common Applications

| Industry | Example use case | Value of AMC |

|---|---|---|

| EV & power electronics | Inverter cold plates, DC/DC thermal modules | CTE control and stiffness for flatness under cycling |

| Aerospace | Compact air-to-liquid exchangers | Weight reduction with dimensional stability |

| Automotive | EGR coolers, charge-air cooling components, thermal management | Better creep/erosion resistance and packaging density |

| Telecom & data infrastructure | Liquid cooling manifolds and cold plates | Reliable interfaces and stable thermal paths |

| Industrial | High-delta-T oil coolers, hydraulic cooling | Wear resistance and mechanical robustness |

Material System Options (Matrix + Reinforcement)

AMC heat exchangers are not a single "one-size" alloy; they are engineered systems. The table below outlines popular combinations and their practical intent.

| Composite system | Typical reinforcement | Typical reinforcement volume fraction | Practical intent |

|---|---|---|---|

| Al-SiC (particulate) | SiC | 10–30% | Higher stiffness, lower CTE, improved wear |

| Al-Al₂O₃ (particulate) | Alumina | 10–25% | Corrosion-robust reinforcement, stable at temperature |

| Al-Graphite (hybrid) | Graphite + ceramic | 5–20% | Thermal conductivity tuning and friction reduction |

| Hybrid AMC | SiC + Al₂O₃ | 10–30% | Balanced machinability, cost, and stability |

Chemical Composition (Representative Matrix Alloys)

The reinforcement is not part of the aluminum alloy chemistry, so composition control focuses on the matrix alloy. Below are common matrix choices used for exchanger components, shown in typical ranges (wt.%). Final selection depends on joining route, corrosion environment, and required strength.

AA3003 (widely used in heat exchanger sheet)

| Element | Si | Fe | Cu | Mn | Mg | Zn | Al |

|---|---|---|---|---|---|---|---|

| Typical wt.% | 0.6 max | 0.7 max | 0.05–0.20 | 1.0–1.5 | 0.05 max | 0.10 max | Balance |

AA6061 (structural plates, manifolds, cold plates)

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Typical wt.% | 0.4–0.8 | 0.7 max | 0.15–0.40 | 0.15 max | 0.8–1.2 | 0.04–0.35 | 0.25 max | 0.15 max | Balance |

Temper / Heat Treatment and Joining Compatibility

AMC heat exchanger designs are often limited not by conductivity, but by joinability and stability after joining. The table summarizes typical temper routes used in practice.

| Matrix family | Common tempers | Notes for heat exchangers | Joining considerations |

|---|---|---|---|

| 3xxx (e.g., 3003) | O, H14, H24 | Excellent formability for fins and sheets | Highly compatible with controlled atmosphere brazing (CAB) when clad |

| 6xxx (e.g., 6061) | T6, T651, O | Higher strength for plates/manifolds | Welding feasible; brazing may require process tuning due to composite effects |

| 5xxx (e.g., 5052/5083) | H32, H116 | Good corrosion resistance in marine-like environments | Welding common; avoid high-temp exposure that risks sensitization (alloy-dependent) |

Technical Specifications (Typical Product Ranges)

Actual values depend on reinforcement, processing method (powder metallurgy, stir casting, squeeze casting, infiltration), and component geometry. These are practical ranges used for customer-level specification.

| Parameter | Typical range | Notes |

|---|---|---|

| Density | 2.75–3.05 g/cm³ | Increases with ceramic fraction; still far below steel/copper systems |

| Thermal conductivity | 140–210 W/m·K | Composite may reduce k vs pure Al; design focuses on stability + thin walls |

| CTE (20–100°C) | 12–20 µm/m·K | Tunable; lower values achievable with higher SiC fraction |

| Elastic modulus | 85–140 GPa | Higher than monolithic aluminum (~69 GPa) |

| Tensile strength (room temp) | 180–420 MPa | Depends heavily on matrix/temper and reinforcement |

| Yield strength (room temp) | 120–350 MPa | Higher values in heat-treated 6xxx-based AMCs |

| Operating temperature (typical) | -40 to 250°C | Depends on coolant chemistry, seals, joining method |

| Maximum design pressure (component-level) | application-specific | Governed by geometry, joint efficiency, fatigue requirements |

Performance Notes That Influence Buying Decisions

| Topic | What changes with AMC | Customer takeaway |

|---|---|---|

| Thermal cycling | Lower CTE and higher stiffness reduce warpage | Better interface stability for cold plates and brazed assemblies |

| Vibration & fatigue | Higher modulus can reduce strain | Helps in mobile and aerospace environments when properly designed |

| Corrosion | Matrix still behaves like aluminum, reinforcement can affect galvanics locally | Use proven coatings, inhibitors, and validated brazing/cladding systems |

| Machinability | Hard phases increase tool wear | Budget for carbide/PCD tooling; optimize feeds/speeds |

Typical Forms and Build Options

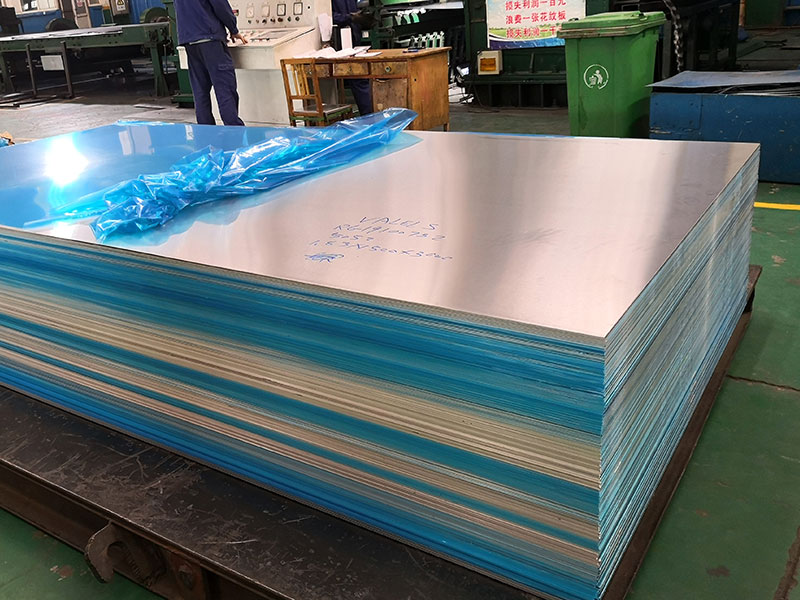

| Product form | Typical use | Manufacturing notes |

|---|---|---|

| AMC sheet/plate | Cold plates, stiffeners, end plates | CNC machining; attention to tool wear and surface finish |

| Extruded profiles | Multiport tubes, manifolds | Dimensional stability and wear resistance are benefits |

| Brazed assemblies | Plate-fin cores with AMC structural parts | Brazing filler/clad selection must be validated with the composite |

| Hybrid assemblies | AMC base + aluminum fins | Cost-effective: composite where it matters, standard Al where it doesn't |

Quality and Inspection (Practical Checks)

| Inspection item | What it controls | Typical method |

|---|---|---|

| Reinforcement distribution | Consistency of properties and joining behavior | Metallography, CT sampling for development builds |

| Porosity | Pressure integrity and fatigue life | Density checks, microscopy, leak tests |

| Flatness & warpage | Thermal interface performance | CMM, optical flatness checks |

| Joint integrity | Long-term reliability | Burst testing, thermal cycling, helium leak tests |

AMC heat exchangers are engineered for compact, lightweight thermal systems that must stay stable under heat, pressure, vibration, and cycling. By combining aluminum's manufacturability with ceramic reinforcement, AMCs offer tunable CTE, higher stiffness, improved wear resistance, and better high-temperature stability-ideal for EV power electronics cooling, aerospace thermal management, and demanding industrial loops. Selection should focus on the full system: matrix alloy, reinforcement fraction, joining route, corrosion control, and inspection plan.

Aluminum matrix composites heat exchanger solutions deliver lightweight, high-stiffness thermal performance with tunable CTE, improved wear resistance, and stable operation for EV, aerospace, and industrial cooling applications.

https://www.aluminumplate.net/a/aluminum-matrix-composites-heat-exchanger.html