Polished Mirror Aluminum Sheet Coil 1050

Polished Mirror Aluminum Sheet Coil 1050: The "Light-Management" Material Customers Often Underestimate

When customers ask for Polished Mirror Aluminum Sheet Coil 1050, they usually focus on one thing: how shiny it looks. A more useful way to evaluate it is to treat it as a light-management material-a coil that doesn't just decorate, but also reflects, amplifies, and controls visual perception in real products. From this viewpoint, choosing the right 1050 mirror coil becomes much easier and more practical.

1) What 1050 Mirror Coil Really Is (and Why It Behaves the Way It Does)

1050 aluminum is a commercially pure aluminum alloy (about 99.5% Al). That purity gives it:

- Excellent formability (easy bending, rolling, stamping)

- High reflectivity potential after polishing

- Strong corrosion resistance for indoor and many mild environments

But it also means: - Lower strength than alloys like 3003/5052

- Surface is softer, so it can scratch more easily if handled poorly

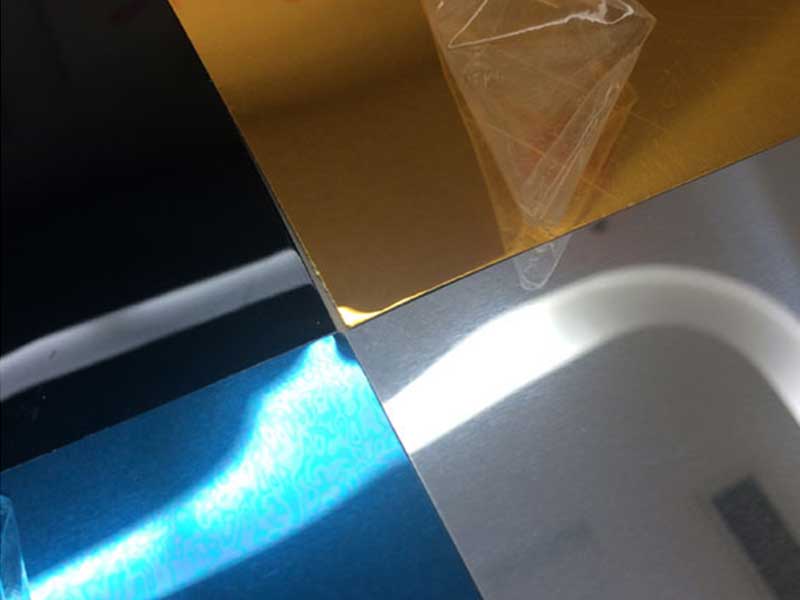

A "mirror" finish is achieved by mechanical polishing and surface finishing, often followed by protective film (and sometimes anodizing or coating depending on the specification).

2) The Distinctive Viewpoint: Buy Mirror Coil for Reflection Performance, Not Just Appearance

From the "light-management" perspective, customers should evaluate three "reflection outcomes":

A. Clarity (Image Sharpness)

- High clarity matters for decorative panels, trims, signage, and interiors where the mirror effect must look clean.

- Ask for confirmation of surface quality level (some suppliers grade mirror as regular mirror / super mirror).

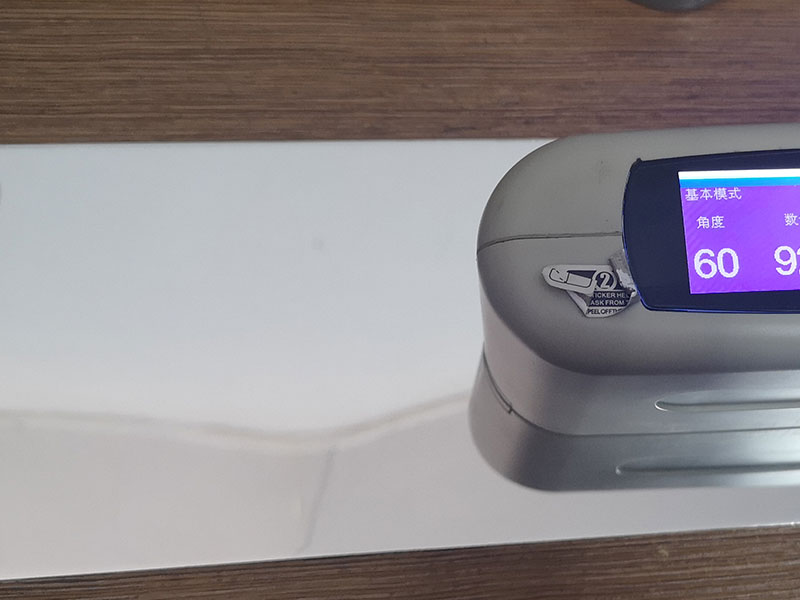

B. Brightness (Total Reflectivity)

- 1050 can reach very high reflectivity with good polishing.

- Useful for lamp reflectors, lighting housings, solar-related reflective parts, and interior brightness enhancement.

C. Consistency (Coil-to-Coil Stability)

- A mirror surface that varies across the coil creates visual "waves" or tone differences after forming.

- Consistency depends on rolling control, polishing process stability, and protection during packing.

3) Practical Details Customers Should Confirm (Fast Checklist)

To avoid "looks good on sample, fails in production," confirm these points:

- Temper: Common options include O (soft) for deep forming, or H14/H24 for better stiffness and flatter panels.

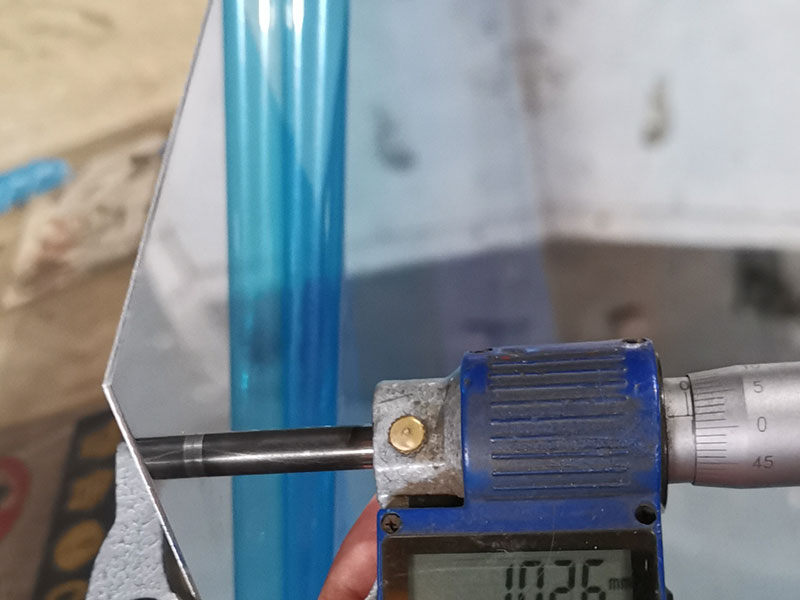

- Thickness & width tolerance: Tight tolerance improves lamination, panel flatness, and assembly fit.

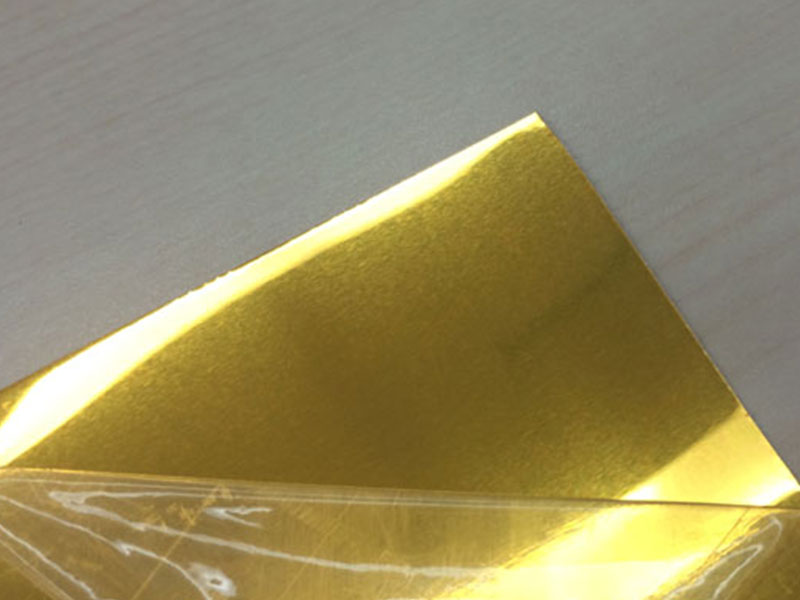

- Surface protection film: Choose film strength based on your process:

- Light film: easy peel, lower protection

- Strong film: better scratch protection, but may leave adhesive risk if stored too long or heated

- Application environment:

- For harsh outdoor exposure, consider anodized mirror or coated alternatives (pure 1050 mirror is corrosion-resistant but surface aesthetics can degrade faster outdoors).

- Packaging: Mirror coil should be packed like a finished decorative product-edge protection, anti-scratch interleaving, moisture control.

4) Where Polished Mirror Aluminum Coil 1050 Makes the Most Sense

Because it balances high reflectivity + easy forming + corrosion resistance, 1050 mirror coil is commonly used in:

- Lighting: reflectors, lamp shades, LED housing liners

- Decoration & interiors: ceiling strips, wall panels, elevator trims

- Appliance and consumer product trims: visual brightening without heavy weight

- Signage and display: reflective elements that increase contrast and visibility

- General industrial reflective parts where strength is not the limiting factor

If the product needs higher structural strength (impact resistance, heavy load, rigid panels), 1050 may not be the best base alloy unless supported by design.

5) The Most Common Failure Is Not the Material-It's Handling

Mirror aluminum is often rejected due to:

- Micro-scratches from rollers, gloves, tables, or stacking

- Film damage during slitting or bending

- Stains from moisture trapped in packaging

A simple rule: treat 1050 mirror coil like a finished cosmetic surface, not like raw metal.

https://www.aluminumplate.net/a/polished-mirror-aluminum-sheet-coil-1050.html