3003 H18 Embossed Aluminum Sheet

In the ever-evolving landscape of design and manufacturing, the materials we choose can be defining factors in both functionality and aesthetic appeal. Among aluminum alloys, 3003 H18 embossed aluminum sheets have carved a niche for themselves as a perfect balance between strength, flexibility, and visual intrigue. But what exactly is it that makes this alloy a favorite in both industrial applications and creative designs?

A Deeper Look into 3003 Aluminum Alloy

Before diving into the specifics of the embossed variant, it’s essential to understand the foundation. 3003 is a part of the 3000 series aluminum alloys, primarily composed of aluminum, with manganese as the principal alloying element (approximately 1.0-1.5% by weight). It is well-known for its workability, good corrosion resistance, and moderate strength. The temper designation H18 indicates that the material has been strain-hardened to a high degree—specifically, it’s subjected to a rigorous cold-working process. This results in enhanced strength characteristics without the need for thermal treatment.

Additionally, the high percentage of manganese allows it to withstand mild acidic environments without deterioration, making it a favorite in the food and chemical processing industries.

The Embossed Advantage

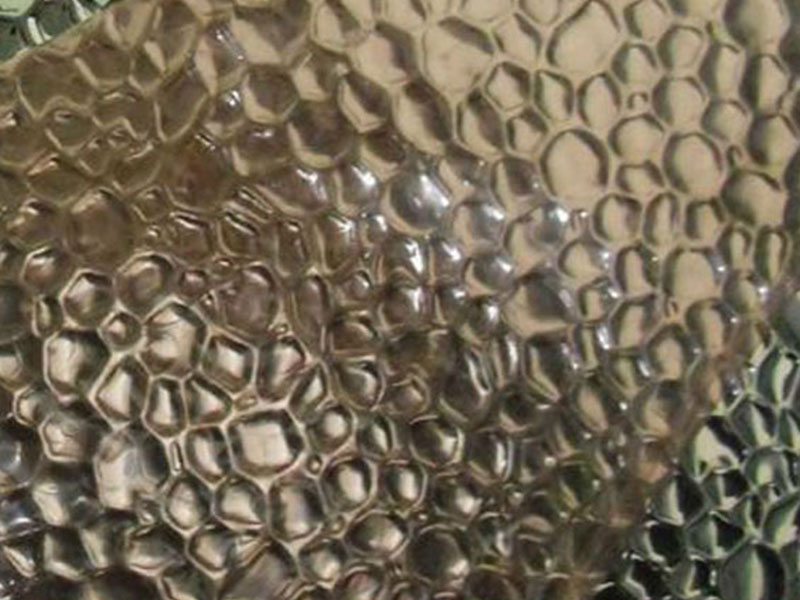

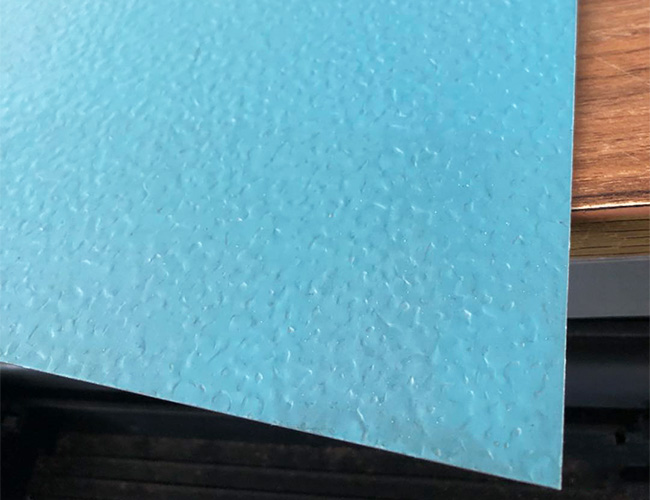

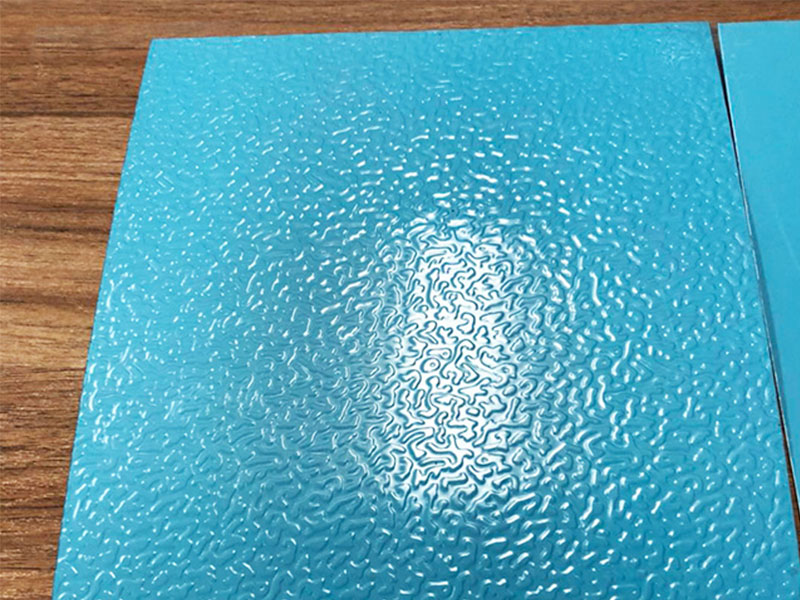

The term embossed describes a manufacturing process that creates a raised or recessed surface design typically used to enhance grip, reflect light, or simply provide visual appeal. This surface alteration dramatically enhances the inherent qualities of 3003 H18 aluminum sheets:

Aesthetic Appeal: The embossed patterns provide a refreshing temperament to what might otherwise be considered a plain metal sheet. Available in different patterns, these designs cater to both functional and aesthetic preferences, making it an ideal choice for applications where visual presentation is paramount.

Increased Stiffness and Strength: The embossing process uniquely increases the stiffness of the material. While the original strength comes from the alloying elements and work-hardening, the pressing creates geometric configurations that distribute loads more evenly across the sheet, enhancing its durability despite being lightweight.

Slip Resistance: Thanks to the embossed surface, traction is significantly improved, benefiting applications in industrial environments, walkways, and flooring, where everyday slip hazards can be a constant concern.

Light Reflection and Heat Insulation: Embossed sheets not only look aesthetically pleasing but also have beneficial properties concerning heat and light. They reflect light well and can be used to diffuse harsh lighting, which is advantageous in architectural elements.

Parameters and Properties

Here’s a quick reference table outlining crucial facts about 3003 H18 Embossed Aluminum Sheets:

| Parameter | Specification |

|---|---|

| Alloy No. | 3003 |

| Temper | H18 |

| Condition | Embossed (raised surface) |

| Thickness Range | 0.024” to 0.190” |

| Width Range | 36” to 60” or custom-sized |

| Yield Strength | 75-100 MPa (10,500-14,500 psi) |

| Ultimate Tensile Strength | 155-200 MPa (22,500-29,000 psi) |

| Elongation | ≤ 2% |

| Corrosion Resistance | Good (resistant to atmospheric corrosion) |

| Common Applications | Decorative panels, insulation cladding, and cooking equipment |

Implementation and Standards

When working with 3003 H18 embossed aluminum sheets, certain implementation standards should be adhered to. Industry-recognized standards such as ASTM B209 (Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate) ensure that the material is up to par relative to quality, safety, and maximum performance levels. Manufacturers will often produce these sheets according to customer specifications on dimensions and desired surface finish, including embossed patterns.

Furthermore, it's critical for applications requiring a significant aesthetic impact to collaborate with experienced suppliers who maintain high consistency in their production practices.

https://www.aluminumplate.net/a/3003-h18-embossed-aluminum-sheet.html