0.45mm 0.55mm 0.6mm thick color coated anodized aluminum sheet

0.45mm, 0.55mm, 0.6mm Thick Color Coated Anodized Aluminum Sheet: Where Surface Engineering Meets Everyday Performance

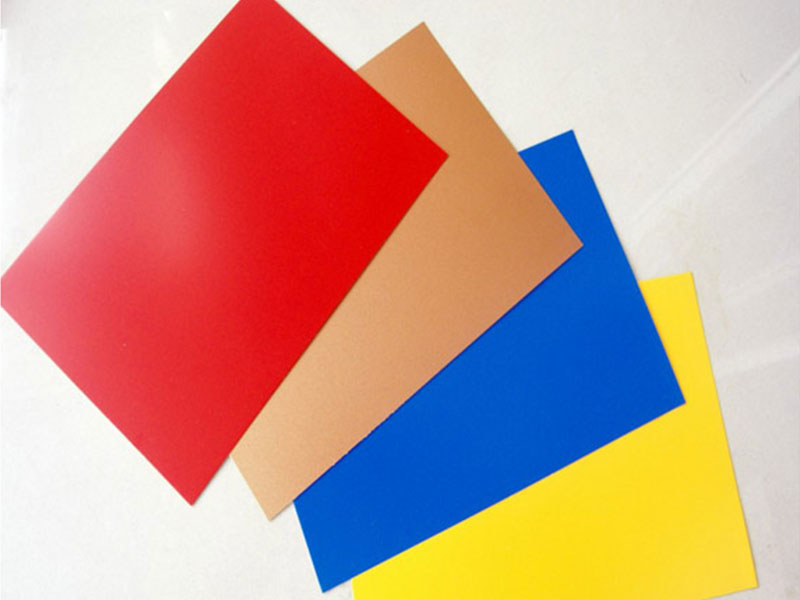

When customers ask for 0.45mm, 0.55mm, or 0.6mm thick color coated anodized aluminum sheet, they're rarely just buying a "thin metal sheet." They are choosing a surface system that has to behave like a finished product: it must stay clean-looking, resist corrosion, hold color, survive forming, and remain stable under sun, rain, salt air, and temperature swings. These three thicknesses sit in a practical sweet spot-rigid enough for panels and skins, light enough for transport and installation, and thin enough to form into profiles, bends, and architectural details.

A useful way to see this material is not as aluminum with paint, but as a layered performance structure. The aluminum alloy provides strength-to-weight and formability. The anodized film improves corrosion resistance and surface hardness while offering a premium metallic appearance. The color coating contributes UV stability, design freedom, and additional barrier protection. Done correctly, the layers don't compete; they complement each other, turning a slim gauge sheet into a long-life exterior or interior finish.

Why these thicknesses are used so widely

In real projects, thickness isn't chosen only by "strength." It's also chosen by feel, flatness, and fabrication tolerance.

0.45mm is often selected where weight and cost control are critical, such as interior ceiling skins, decorative cladding layers, roll-formed trims, signage backers, and appliance or furniture skins. It bends easily and suits continuous coating production.

0.55mm is a balanced option for general architectural skins, wall and fascia systems, shutter slats, and moderate-span panels where installers want a bit more rigidity and dent resistance without a major weight jump.

0.6mm is commonly used when the panel must feel "stiffer in hand," tolerate more handling on site, or support larger cassette faces and formed edges. It is also chosen for transportation equipment interiors and exterior trims where vibration and minor impacts are expected.

Across all three gauges, the goal is the same: a stable substrate that can be cut, punched, folded, and fastened without sacrificing coating integrity.

Functional value: what the sheet is actually "doing" in service

Color coated anodized aluminum sheet is essentially a corrosion-management and appearance-management material.

The anodized layer is a controlled oxide film that improves resistance against oxidation and weathering. It also increases surface hardness compared with bare aluminum, helping with scuff resistance. When paired with a quality coating system, it creates a robust barrier against moisture, industrial pollutants, and UV-driven degradation.

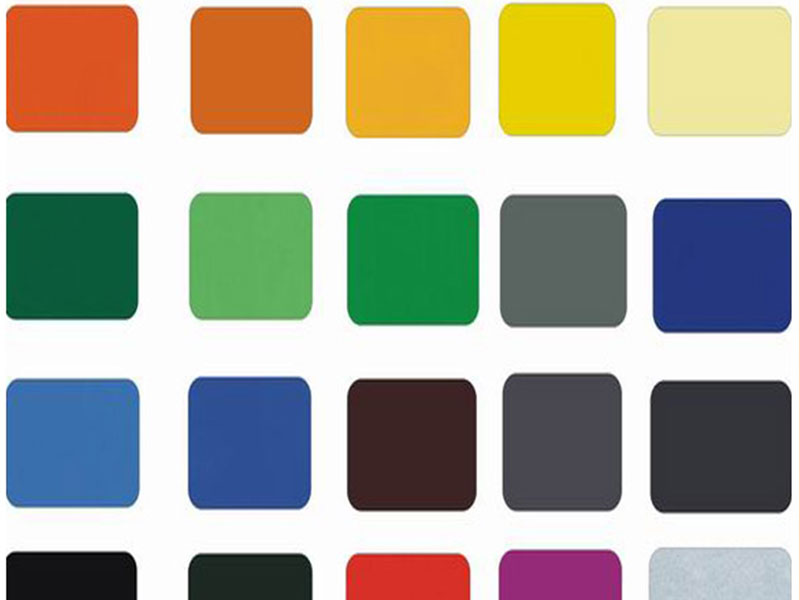

The color coating adds the visual identity and extends durability. PVDF coatings are favored for exterior architectural use due to excellent UV retention and chalk resistance. Polyester (PE) coatings are widely used for interior applications or cost-sensitive projects with good performance in less aggressive exposure. Specialized coatings can add anti-graffiti behavior, low-gloss premium aesthetics, antibacterial features for clean environments, or enhanced abrasion resistance.

The most distinctive advantage is consistency. With coil-coated sheet, color, gloss, and film thickness are controlled industrially rather than on-site, making it easier to match large building elevations, modular wall systems, and brand-signage surfaces.

Typical parameters customers care about

Even for quick procurement decisions, a few parameters define quality clearly.

Thickness options discussed here are 0.45mm, 0.55mm, and 0.6mm, typically with thickness tolerance controlled by the base sheet standard and the producer's rolling capability. Common widths range from 1000mm to 1250mm, with custom slitting available; coil supply is typical for roll forming, while sheets are cut-to-length for panel fabrication.

Coating systems are commonly PE, SMP, HDP, and PVDF. For outdoor durability, PVDF topcoats are frequently specified at 25 μm or higher topcoat thickness, with primer around 5 μm; PE systems are often thinner and selected for indoor or moderate exposure. Back coating is typically 5–10 μm depending on application.

Anodizing film thickness is commonly in the 5–15 μm range for decorative purposes, while tougher environments may require thicker anodic films. Final selection should match exposure class and fabrication method, since heavy forming can favor certain coating chemistries and primer choices.

Implementation standards and reference specifications

Different projects reference different standards depending on region and industry. Commonly used benchmarks include:

Aluminum sheet and alloy requirements are often aligned with ASTM B209 (USA) or EN 485 / EN 573 (Europe) for wrought aluminum and aluminum alloys, including mechanical properties and tolerances.

Anodizing quality and film characteristics are frequently evaluated with ISO 7599 for anodizing of aluminum and its alloys, while architectural anodizing is often specified with AAMA 611.

Coil coating performance is commonly referenced by AAMA 2603, AAMA 2604, and AAMA 2605, which correspond to increasing levels of weathering performance (with AAMA 2605 typically aligned with premium PVDF architectural expectations).

Coating thickness, adhesion, impact resistance, flexibility, and salt spray resistance are typically verified through standardized test methods such as ISO 2409 (cross-cut adhesion) and ASTM B117 (salt spray), among others selected by buyer specification.

Alloy selection and tempering: the substrate that makes forming and strength possible

For thin-gauge coated aluminum sheet, the most used alloys are 1xxx, 3xxx, and 5xxx series depending on desired formability and strength.

1050, 1060, 1100 are high-purity options with excellent formability and conductivity, commonly used for general decorative and forming applications where high strength is not required.

3003 and 3005 provide a strong balance of formability, corrosion resistance, and moderate strength, making them very common for architectural skins, cladding, and coated sheet products.

5052 offers higher strength and superior resistance in marine or salty environments, often selected when corrosion resistance and fatigue performance matter more than easiest forming.

Temper choices typically include O (annealed) for maximum ductility and bending ease, H14/H24 for a balance of strength and formability, and H16/H26 when higher stiffness is required. For 0.45–0.6mm, H24 is often a practical choice for panels that must resist oil-canning while still allowing folding and light forming.

Chemical properties table (typical ranges)

Actual chemistry depends on the selected alloy standard (ASTM/EN/GB). Below are typical composition limits for common sheet alloys used with coating/anodizing. Values are in weight percent.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 1100 | ≤1.0 | ≤1.0 | 0.05–0.20 | ≤0.05 | ≤0.05 | - | ≤0.10 | ≤0.05 | ≥99.0 |

| 3003 | ≤0.6 | ≤0.7 | 0.05–0.20 | 1.0–1.5 | ≤0.05 | - | ≤0.10 | ≤0.10 | Balance |

| 3005 | ≤0.6 | ≤0.7 | ≤0.30 | 1.0–1.5 | 0.2–0.6 | ≤0.10 | ≤0.25 | ≤0.10 | Balance |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.10 | Balance |

Note: "Balance" indicates the remainder is aluminum after alloying elements and impurities.

Applications: where the layered performance pays off

Architectural cladding and façade trims benefit from color stability, cleanability, and corrosion protection, especially when PVDF systems are used. These gauges are also common in soffits, fascia, and eaves where long, flat lines demand consistent gloss and minimal waviness.

Ceilings, partitions, and interior wall skins use thin coated anodized sheet to create premium metallic reflections and refined color palettes while keeping structures lightweight.

Signage, branding panels, and retail fit-outs value repeatable color and finish across multiple stores or regions. The anodized base feel adds a "technical luxury" look that ordinary painted metals sometimes lack.

Appliance and equipment skins, HVAC panels, and enclosures use these thicknesses for clean aesthetics and practical scratch resistance, with coating selection matched to chemical exposure and cleaning frequency.

Transportation interiors and light exterior trims benefit from weight reduction and corrosion performance, especially in humid or salt-prone operating environments.

A distinctive way to specify it: think in "service life layers"

Instead of selecting only thickness and color, specify by service reality: exposure, forming, and cleaning. Match alloy and temper to the fabrication method, choose anodic film thickness for the environment, and select coating chemistry for UV and chemical contact. When these elements align, 0.45mm, 0.55mm, and 0.6mm color coated anodized aluminum sheet becomes less like a commodity and more like a designed surface-engineered to stay attractive and functional long after installation.

https://www.aluminumplate.net/a/045mm-055mm-06mm-thick-color-coated-anodized-aluminum-sheet.html