Ground aluminum plate

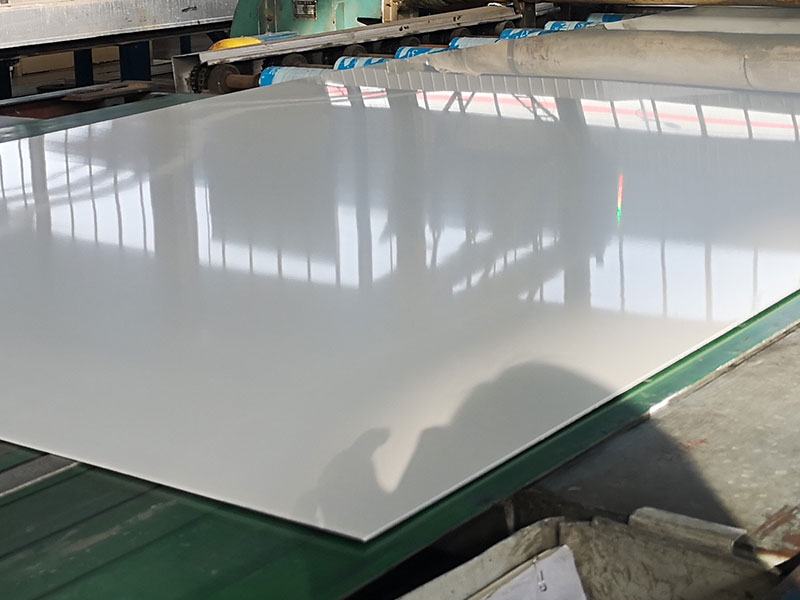

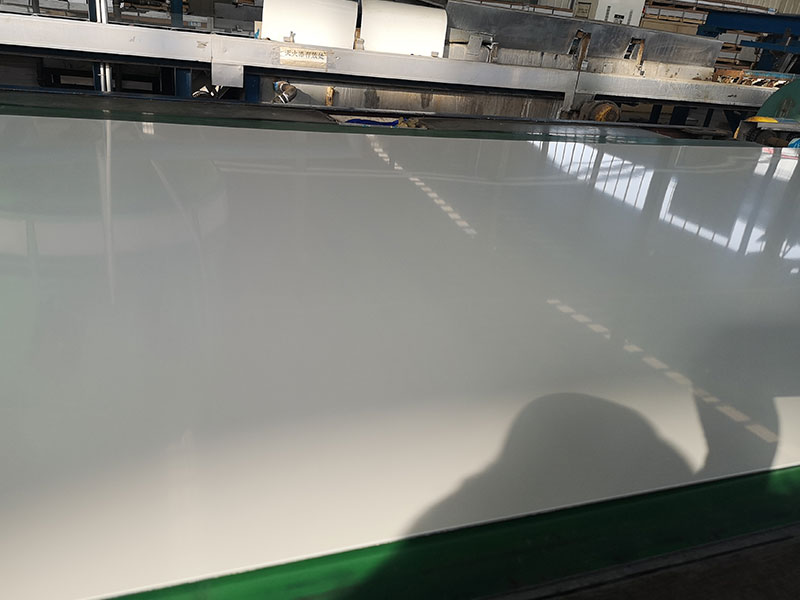

Ground aluminum plate is a precision-processed aluminum plate whose surfaces are mechanically ground to achieve controlled thickness, improved flatness, and a uniform finish. Compared with standard mill-finish plate, a ground plate is designed for customers who care about consistent contact surfaces, predictable machining behavior, and reliable assembly fit-especially in jigs, fixtures, automation bases, molds, panels, and equipment beds.

Instead of "looking shiny," the goal is functional uniformity: reduced surface waviness, minimized high spots, and a stable datum surface that helps components sit flat and clamp evenly. When paired with the right alloy and temper, ground aluminum plate becomes a practical alternative to steel in many platforms where weight, corrosion resistance, and machinability matter.

What Makes a Plate "Ground"?

A ground aluminum plate is typically produced by taking a rolled plate (cast tool-and-jig plate or wrought plate) and applying controlled grinding passes to one or both faces. The result is a plate with:

- More uniform thickness across the surface

- Improved flatness for assembly and inspection surfaces

- A consistent, fine linear texture that supports measurement marking and light sealing contact

- Reduced machining surprises, such as rocking on a table or uneven clamping pressure

Ground finishes are commonly specified when the plate will be used as a reference surface or when a customer wants to reduce preparation time before CNC machining.

Features Customers Notice in Use

| Feature | What it means in practice | Customer benefit |

|---|---|---|

| Controlled thickness | Grinding reduces local thickness variation | Less shimming, faster setup |

| Better flatness and contact | Fewer high spots and waviness | Stable fixtures, better alignment |

| Uniform surface texture | Fine grinding lines, reduced random defects | Easier marking, consistent appearance |

| Machining-friendly behavior | More predictable cuts on the first face | Shorter cycle time, less rework |

| Lightweight strength | Aluminum's high strength-to-weight ratio | Easier handling, lower equipment mass |

| Corrosion resistance | Natural oxide layer; can be anodized | Better durability in humid environments |

Common Alloy Options and How to Choose

Ground aluminum plate is available in multiple alloys, each tailored to a different "job." Below are common choices customers request for industrial plate applications.

Typical Alloy Selection Guide

| Alloy / temper (typical) | Best known for | Typical uses |

|---|---|---|

| 6061-T6 / T651 | Balanced strength, corrosion resistance, weldability | Machine bases, plates, brackets, frames |

| 5083-H116 / H321 | Excellent marine corrosion resistance | Deck hardware, offshore fixtures, corrosive environments |

| 7075-T651 | High strength and stiffness | High-load fixtures, aerospace tooling, performance parts |

| MIC-6 / cast tool-and-jig plate (varies) | Stability and flatness for tooling | Jigs, fixtures, vacuum plates, inspection tooling |

Your selection typically depends on whether the priority is machinability, corrosion resistance, weldability, or maximum strength.

Chemical Composition (Reference Ranges)

Actual composition depends on standards and mill certification; the tables below provide commonly referenced ranges for popular alloys used for ground plate.

6061 (typical composition, wt.%)

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Typical range | 0.40–0.80 | ≤0.70 | 0.15–0.40 | ≤0.15 | 0.80–1.20 | 0.04–0.35 | ≤0.25 | ≤0.15 | Balance |

5083 (typical composition, wt.%)

| Element | Mg | Mn | Cr | Si | Fe | Cu | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Typical range | 4.0–4.9 | 0.4–1.0 | 0.05–0.25 | ≤0.40 | ≤0.40 | ≤0.10 | ≤0.25 | ≤0.15 | Balance |

7075 (typical composition, wt.%)

| Element | Zn | Mg | Cu | Cr | Si | Fe | Mn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Typical range | 5.1–6.1 | 2.1–2.9 | 1.2–2.0 | 0.18–0.28 | ≤0.40 | ≤0.50 | ≤0.30 | ≤0.20 | Balance |

Technical Specifications Customers Commonly Request

Because "ground plate" is often used as a functional reference surface, customers usually specify measurable parameters instead of general descriptions.

Standard Supply Parameters (typical request format)

| Parameter | Typical options | Notes |

|---|---|---|

| Thickness range | 6 mm to 100+ mm | Thicker plates often used for bases and tooling |

| Width / length | Cut-to-size or full sheets/plates | Saw-cut edges; milling available on request |

| Ground sides | One side ground or both sides ground | Both sides when parallelism and contact are critical |

| Surface roughness (Ra) | Commonly 0.8–3.2 µm | Target depends on sealing/inspection needs |

| Flatness tolerance | Application-dependent | Tooling plates often call for tighter flatness |

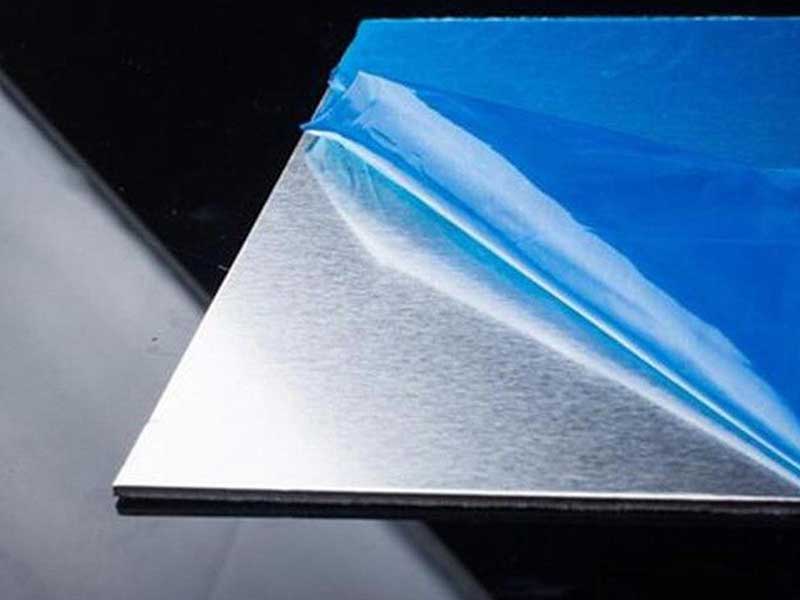

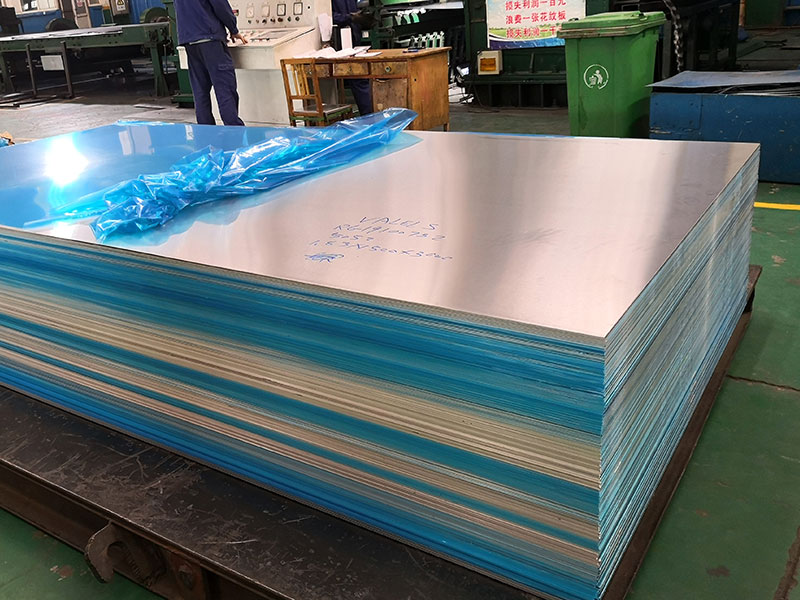

| Protective film | Optional PVC/PE film | Helps prevent handling scratches |

| Certification | Mill test report on request | Confirms chemistry and mechanical properties |

Mechanical Performance (Typical Values)

Mechanical properties depend on temper, thickness, and product form. Values below are commonly referenced for quick comparison.

| Alloy / temper | Yield strength (MPa) | Tensile strength (MPa) | Elongation (%) | Notes |

|---|---|---|---|---|

| 6061-T6/T651 | ~240 | ~290 | ~8–12 | Great general-purpose machining plate |

| 5083-H116 | ~215 | ~305 | ~10–16 | Excellent corrosion resistance, not heat-treatable |

| 7075-T651 | ~500 | ~570 | ~7–11 | High strength; corrosion protection often recommended |

Where Ground Aluminum Plate Excels

Ground aluminum plate is chosen when flatness and repeatability improve the downstream process. The following applications capture why customers buy it even when standard plate is cheaper.

Tooling, jigs, and fixtures

A ground surface helps fixtures sit reliably on machine tables and reduces setup variability. For modular fixtures, a stable plate can act as a "mechanical canvas" for dowel holes, threaded inserts, and precision pockets.

| Fixture use case | Why ground plate helps |

|---|---|

| CNC fixture base | Better clamping consistency, less rocking |

| Drill and tap templates | Improved datum surfaces for hole position repeatability |

| Vacuum fixture plates | More uniform sealing contact, less leak risk |

Automation and equipment base plates

Automation frames and base plates benefit from weight savings and corrosion resistance while still holding machined geometry. Ground plate is often used for sensor mounts, linear rail bases, and indexing equipment.

| Application | Typical alloy | Typical reason |

|---|---|---|

| Linear guide mounting plate | 6061-T651 | Balanced stiffness and machinability |

| Robotic cell base panel | 6061 or 5083 | Reduced weight, corrosion resistance |

| Inspection station base | Tooling plate / 6061 | Stable flat surface for metrology fixtures |

Molds, patterns, and prototype builds

For short-run molds or prototype tooling, aluminum's machinability cuts lead time. Ground plate reduces the prep required to create a reference face and can improve the quality of early machining operations.

Finishing and Secondary Processing Options

Ground aluminum plate is often a "starting surface" that can be upgraded depending on the environment.

| Option | What it adds | Typical reason to choose it |

|---|---|---|

| Anodizing (Type II) | Improved corrosion resistance and appearance | Panels, exposed equipment, light wear |

| Hard anodizing (Type III) | Higher surface hardness | Sliding contact, wear surfaces |

| Painting / powder coating | Barrier protection and color | Branding, chemical exposure mitigation |

| Precision machining | Tight tolerances, hole patterns | Final functional features |

Practical Buying Notes

| Customer question | Practical guidance |

|---|---|

| One-side or two-side ground? | One-side for a reliable datum; two-side when parallelism and double-face contact matter |

| Which alloy is safest for general use? | 6061-T651 is the most common "do-it-mostly-all" choice |

| Will it stay flat after machining? | Stress-relieved tempers help; symmetric machining and good clamping reduce distortion |

| How to protect the finish during handling? | Specify protective film and use clean separators during stacking |

Ground aluminum plate is built for repeatable flat contact, dependable thickness control, and efficient machining. It bridges the gap between raw mill plate and fully machined tooling, giving customers a practical shortcut to better setups and cleaner downstream processes. When selected with the right alloy-such as 6061 for general machining, 5083 for corrosion-heavy environments, or 7075 for high-load tooling-ground aluminum plate becomes a high-value material for fixtures, automation platforms, inspection bases, and precision industrial assemblies.