5005 H36 Aluminum Plate

5005 H36 aluminum plate is a corrosion-resistant, medium-strength aluminum-magnesium alloy product built for appearance-critical panels, durable sheet metal fabrication, and anodized architectural components. It is often chosen when customers want the clean surface and anodizing quality associated with 5005, plus the added strength and dent resistance delivered by the H36 temper (strain-hardened to a higher level within the H3x family).

This plate grade sits in a practical "sweet spot": it forms and welds well, holds up in humid or mildly marine atmospheres, and produces a bright, uniform finish when properly prepared-making it a favorite for architectural trims, equipment housings, appliance panels, signage, and transportation interiors.

What "5005" and "H36" Mean in Practice

Alloy 5005 belongs to the Al-Mg (5xxx) family. Its magnesium level is lower than high-strength marine alloys like 5083, but it is deliberately balanced to deliver:

- Excellent corrosion resistance in atmospheric exposure

- High-quality anodizing response, often better matched for decorative anodized work than some other 5xxx alloys

- Good fabrication behavior for bending, punching, and general sheet-metal operations

Temper H36 indicates the plate is strain hardened and stabilized. In practical customer terms, H36 generally means:

- Higher yield/ultimate strength than H32/H34 variants

- Better resistance to handling damage (dings, "oil-canning") in wide panels

- Slightly reduced formability compared with softer tempers, while still remaining workable for many bends and shapes

Features Customers Notice

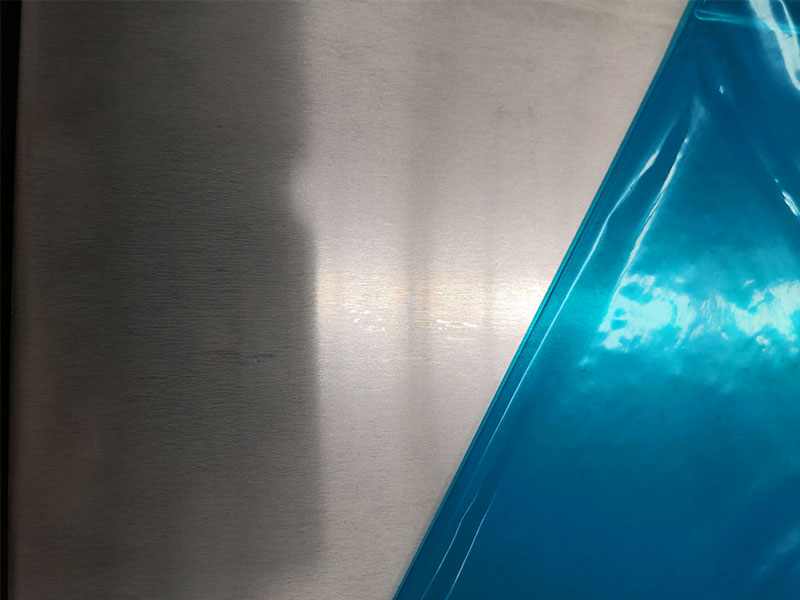

Appearance-friendly surface for anodizing and finishing

5005 is widely selected for decorative anodizing, especially when customers want consistent color and a clean, uniform look. With proper pretreatment and process control, it can deliver a bright, even anodized finish suitable for visible architectural pieces.

Corrosion resistance for real-world environments

The 5xxx series is naturally strong in humid, industrial, and coastal-adjacent atmospheres. While 5005 is not the highest-strength marine alloy, it performs very well for exterior trims, enclosures, and panels where durability and appearance are both important.

A balance of strength and workability

H36 provides a noticeable strength increase for "panel stiffness," which helps reduce distortion in fabricated assemblies. It remains compatible with typical shop operations such as cutting, drilling, punching, and many forming tasks.

Welding compatibility

5005 can be welded using common processes (GMAW/MIG, GTAW/TIG). Like most strain-hardened tempers, welding will locally soften the heat-affected zone, so designers should consider joint placement and section thickness when strength is critical.

Chemical Composition (Typical, AA 5005)

The composition below reflects common industry limits for AA 5005. Actual mill certificates may vary within specification ranges.

| Element | Content (wt. %) |

|---|---|

| Magnesium (Mg) | 0.5–1.1 |

| Silicon (Si) | ≤0.30 |

| Iron (Fe) | ≤0.70 |

| Copper (Cu) | ≤0.20 |

| Manganese (Mn) | ≤0.20 |

| Chromium (Cr) | ≤0.10 |

| Zinc (Zn) | ≤0.25 |

| Titanium (Ti) | ≤0.20 |

| Others (each) | ≤0.05 |

| Others (total) | ≤0.15 |

| Aluminum (Al) | Balance |

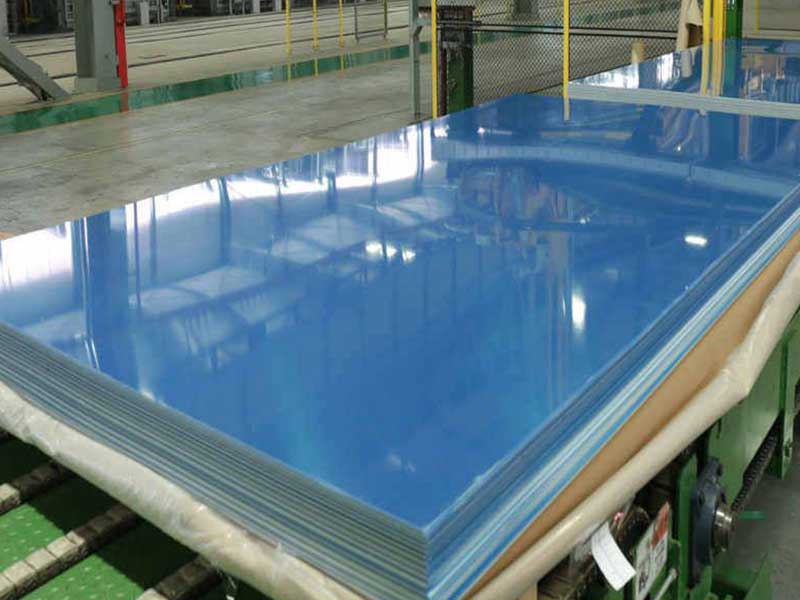

Technical Specifications (Typical Supply Scope)

5005 H36 is commonly supplied as plate (and heavy sheet), with requirements often aligned to ASTM/EN standards depending on region and project.

| Item | Typical Options / Notes |

|---|---|

| Product form | Plate / heavy sheet |

| Temper | H36 (strain hardened, stabilized) |

| Thickness range | Commonly ~3–50 mm (availability depends on mill route and width) |

| Width | Commonly up to ~2000 mm (wider available by inquiry) |

| Length | Commonly up to ~6000 mm (custom cutting available) |

| Surface | Mill finish, brushed, protective film optional |

| Standards (typical) | ASTM B209 (sheet/plate), EN 485 / EN 573 (regional equivalents) |

| Flatness options | Standard flatness; improved flatness available for panel applications |

| Typical fabrication | Cutting, CNC routing, drilling, punching, bending, welding |

Typical Mechanical Properties (Room Temperature, H36)

Mechanical properties depend on thickness, direction, and production route. Values below represent typical ranges customers can use for preliminary selection; final design should rely on mill test reports and relevant standards.

| Property | Typical Value / Range |

|---|---|

| Ultimate tensile strength (UTS) | ~190–230 MPa |

| Yield strength (0.2% proof) | ~150–200 MPa |

| Elongation (A50) | ~4–10% |

| Brinell hardness (HBW) | ~55–75 |

| Density | ~2.70 g/cm³ |

| Melting range | ~605–650 °C |

| Thermal conductivity | ~180–210 W/m·K |

| Electrical conductivity | ~32–40 %IACS |

Performance Notes That Help Customers Choose Correctly

| Topic | Practical Guidance |

|---|---|

| Forming | H36 bends tighter than softer tempers can crack if radii are too small; use larger inside radii and proper grain orientation when possible |

| Welding | Weldable; expect strength reduction near welds due to annealing effect; select filler based on service needs and finish requirements |

| Machining | Machines cleanly with sharp tooling and good chip evacuation; use appropriate lubricants to maintain surface quality |

| Corrosion | Excellent in atmospheric exposure; suitable for outdoor architectural use; consider protective design for trapped moisture/crevices |

| Anodizing | Strong reputation for decorative anodizing; consistent pretreatment and batch control improve color uniformity |

| Surface protection | Protective film recommended for high-visibility parts to prevent handling scratches |

Applications: Where 5005 H36 Aluminum Plate Fits Best

Architectural and building components

5005 H36 is frequently specified for visible architectural elements where both durability and a refined finish matter. Typical uses include:

- Exterior and interior decorative panels

- Column covers, trims, fascias, soffits

- Curtain wall and cladding accessories where anodized appearance is desired

- Retail and public-space feature surfaces that need corrosion resistance and easy cleaning

Its performance is especially attractive for projects seeking anodized aluminum aesthetics rather than painted surfaces, while still offering solid dent resistance during installation and service.

Transportation and interior paneling

In trailers, buses, rail interiors, and specialty vehicles, 5005 H36 is used for:

- Interior wall and ceiling panels

- Luggage rack components and covers

- Equipment partitions, protective linings, and decorative trims

The H36 temper adds stiffness to reduce panel flutter and waviness, helping assemblies look cleaner under lighting.

Appliance, enclosure, and equipment housings

Industrial and consumer equipment often needs a mix of formability, corrosion resistance, and an attractive finish. Common examples:

- Electrical cabinets and covers

- HVAC panels and shrouds

- Food-service equipment skins (where alloy selection aligns with hygiene and finish needs)

- Nameplates, signage backers, and display structures

Signage and display fabrication

For anodized or brushed signage products that must stay crisp outdoors, 5005 H36 offers:

- Good surface response to brushing and polishing

- Stable stiffness for larger sign faces

- Reliable corrosion performance for long service life

Why Customers Pick 5005 H36 Over Nearby Alternatives

| If you are comparing… | What 5005 H36 typically offers |

|---|---|

| Versus 3003 (Al-Mn) | Better anodizing aesthetics and corrosion resistance; usually higher strength in H36 |

| Versus 5052 (Al-Mg) | Often favored for decorative anodizing and surface appearance; 5052 may lead in strength/forming depending on temper |

| Versus 5083/5754 | Those can be stronger/more marine-focused; 5005 is often chosen for finish quality and cost-effective architectural performance |

Ordering Tips (Fast Checklist)

| Topic | What to specify |

|---|---|

| Temper | Confirm H36 for stiffness/strength needs |

| Surface | Mill finish vs brushed; protective film if appearance-critical |

| Thickness tolerance | Standard vs tighter tolerances for precision panels |

| Flatness | Standard vs improved flatness for wide cladding/sign faces |

| Cutting | CNC cut, sheared, or sawed; edge condition expectations |

| Certification | Mill test certificate, standard compliance, and inspection needs |

5005 H36 aluminum plate is a strong choice for customers who want a clean, finish-forward aluminum plate with reliable corrosion resistance and practical fabrication performance. It excels in architectural panels, anodized trims, equipment housings, signage, and transportation interiors, where stiffness and surface quality matter as much as durability. When specified with the right thickness, flatness, and surface protection, 5005 H36 delivers a polished, professional result from fabrication through installation and long-term service.

https://www.aluminumplate.net/a/5005-h36-aluminum-plate.html