5052 5083 5086 5154 5754 5454 5456 Marine grade aluminum

In the realm of marine engineering, material selection is not merely a matter of structural necessity but a strategic decision shaping durability, safety, and performance at sea. Among the myriad options, marine grade aluminum alloys is know for their innovative blend of lightweight strength, corrosion resistance, and adaptability suited for harsh marine environments. Specifically, alloys such as 5052, 5083, 5086, 5154, 5754, 5454, and 5456 embody characteristics tailored to meet diverse maritime challenges from small boats to large ships.

the Core Strengths of Marine Aluminum Alloys

Marine aluminum alloys are primarily non-heat treatable 3000 and 5000 series alloys, valued for their excellent corrosion resistance—especially to saltwater—and formidable mechanical properties. Their high magnesium content contributes significantly to their strength and corrosion resistance, making them ideal for galvanic and mechanical stress conditions encountered at sea.

Diving Into the Specific Alloys: Unique Roles and Attributes

- 5052 Aluminum Alloy – The Marine Workhorse with Great Formability

5052 stands as one of the most versatile marine-grade alloys, prized for its exceptional corrosion resistance and good formability. These properties make it suitable for fuel tanks, chemical storage, and interior paneling where durability alongside ease of fabrication matters. Its higher magnesium content (up to 2.5%) yields medium-strength properties—adequate to withstand marine environmental stresses without overly burdensome weight.

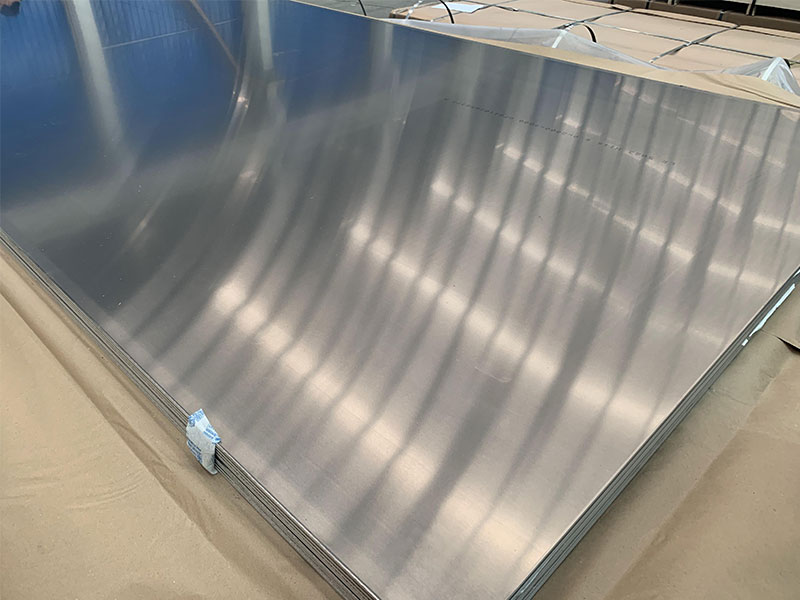

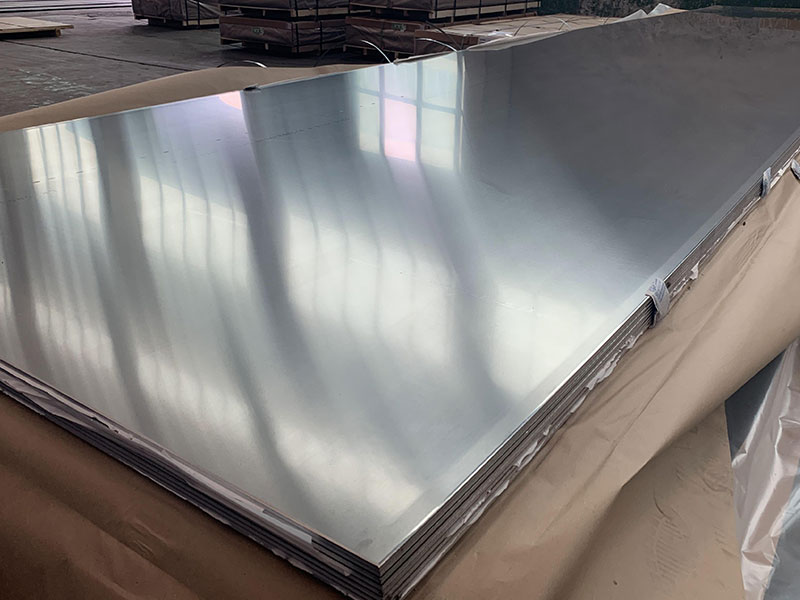

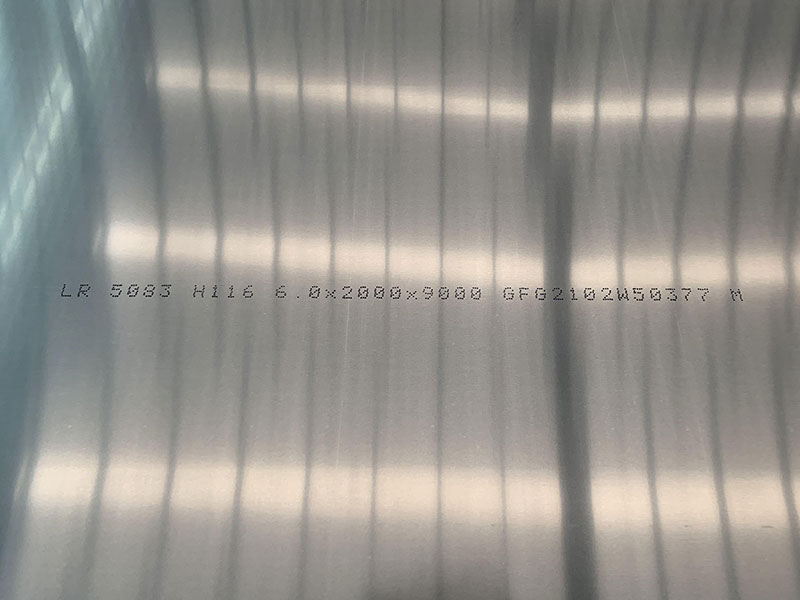

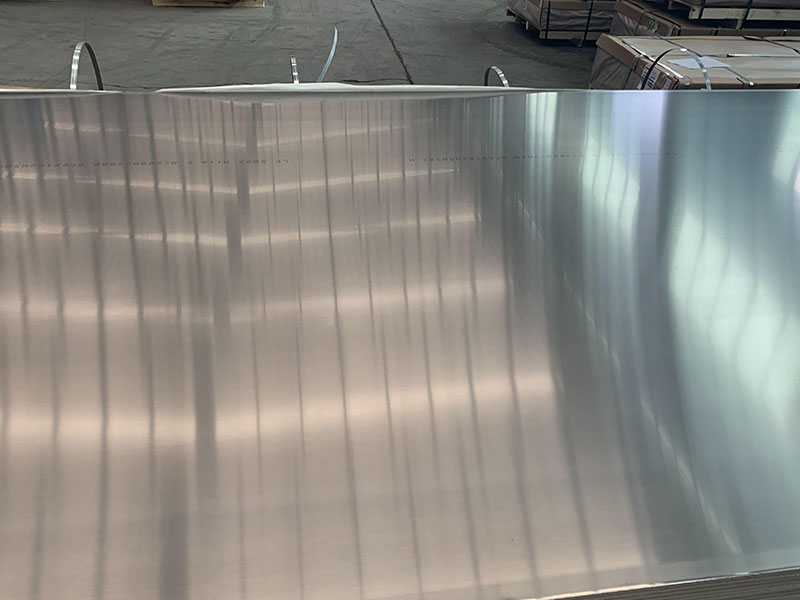

- 5083 and 5086 Alloys – Heavy-Hitters for Extreme Environments

Both 5083 and 5086 are renowned for their superior performance in rugged environments:

5083: Known for exceptional seawater corrosion resistance and facile weldability, this alloy maintains its strength at cryogenic temperatures—ideal for vessels operating in polar regions or cold waters. Its high magnesium (~4.5%) content imparts excellent resistance to bruising and cracking under mechanical stress, notably in ship hulls, winches, and pressure vessels.

5086: Slightly lower in magnesium (~4.0%) but with outstanding ductility and corrosion resistance, often used in floating structures and patrol boats. Its balance of strength and workability makes it an industry favorite for complex fabrications.

- 5154, 5454, and 5456 Alloys – Premium Mixes of Strength and Resilience

These 5000 series alloys traverse the middle ground, with tailor-made properties:

- 5154: Offers a comprehension of moderate strength and good corrosion resistance; fitting for maritime fuel tanks or profiles subjected to mechanical impacts.

- 5454 and 5456: These are alloying innovations boasting improved corrosion resistance and increased strength compared to 5052, especially with applications demanding sharper structural integrity under dynamic stresses or corrosive exposure.

- 5754 Alloy – Bridging the Gap of Strength and Corrosion Resistance

While less discussed, 5754 has merits primarily in applications needing moderate strength combined with excellent weldability and corrosion performance, such as in interior panels and decorative applications aboard vessels.

Advantages of Using These Marine Aluminum Alloys

- Corrosion Resistance: Magnesium-rich 5000 series alloys have thin oxide films that shield against saltwater corrosion, reducing maintenance costs and extending vessel life.

- Lightweight: Significantly reduces vessel weight, increasing fuel efficiency and payload capacity.

- Ease of Fabrication: Good welding, bending, and machining capabilities save time and cost during construction.

- High Strength-to-Weight Ratio: Supports structural integrity that defies traditional heavyweight materials like steel, essential for fast, efficient marine crafts.

From a Practical Perspective: Reliability & Longevity

Choosing the right alloy isn’t a one-size-fits-all decision. While 5083 and 5086 are best suited for extreme marine environments, alloys like 5052, 5154, and 5754 can suffice in less aggressive scenarios. Successful selection hinges on the specific operational conditions, including mechanical loads, types of corrosion exposure, and fabrication methods.

Moreover, surface treatments—like anodizing or coating—further augment the corrosion resistance tailored to particular marine applications, amplifying the benefits of these alloys.

5052 5083 5086 5154 5454 5456 5754

https://www.aluminumplate.net/a/5052-5083-5086-5154-5754-5454-5456-marine-grade-aluminum.html