1060 H112 mirror finish aluminum sheets plates

1060 H112 Mirror Finish Aluminum Sheets Plates: Functions, Standards, and Real-World Performance

1060 H112 mirror finish aluminum sheets and plates occupy a very specific niche in the metal materials world: ultra-high purity, visually striking reflectivity, and stable, predictable mechanical behavior. When designers, engineers, and fabricators choose 1060 H112, they are often balancing aesthetics with conductivity, corrosion resistance, and ease of processing rather than chasing maximum strength.

What 1060 H112 Really Means

The designation “1060 H112” already tells you a lot about the material’s behavior.

- 1060 indicates a high-purity aluminum alloy with approximately 99.6% aluminum content. It belongs to the 1xxx series, known for excellent electrical and thermal conductivity, good corrosion resistance, and exceptional ductility.

- H112 describes the temper: this is a strain-hardened but non-heat-treated condition, typically supplied as wrought products that have undergone some shaping (like rolling or extrusion), with no specific mechanical property levels beyond processing limits. In practice, H112 for 1060 means “as fabricated” but controlled enough to ensure reliable forming performance without brittleness.

For mirror finish sheets and plates, this combination is ideal. The material is soft enough to be polished and bright-rolled to a high reflectivity, yet stable enough to remain flat, formable, and resistant to cracking in bending and shallow drawing.

Why 1060 Is Preferred for Mirror Finishes

Mirror finish aluminum depends on surface purity and consistent microstructure. The fewer alloying elements present, the easier it is to achieve a defect-free, highly reflective surface. 1060 aluminum offers:

- Low impurity content, which minimizes surface inclusions that scatter light

- Excellent response to rolling and polishing processes

- Good compatibility with anodizing and protective coatings, if needed

Unlike harder alloys (like 5xxx or 6xxx), 1060 does not prioritize strength. Instead, it optimizes reflectivity, conductivity, and malleability—for decorative, reflective, and energy-related applications.

Core Functional Advantages

From a functional perspective, 1060 H112 mirror finish aluminum sheets and plates deliver three main performance pillars:

Reflective function

The polished or bright-rolled surface can achieve high specular reflectance, enabling it to redirect light or radiant heat efficiently. This is crucial in lighting systems, solar reflectors, and architectural elements where light management is a core design task.

Conduction and dissipation

With high aluminum purity, 1060 offers excellent electrical and thermal conductivity. When used in power equipment panels, LED back plates, or cooling housings, it helps spread and dissipate heat while also serving as a structural and reflective element.

Formability and appearance stability

In the H112 temper, 1060 can be cut, bent, stamped, embossed, and shallow-drawn with minimal risk of cracking. The mirror surface remains intact when processing is done correctly, making it practical for visible parts that must maintain a flawless appearance after fabrication.

Typical Applications: Where the Mirror Surface Becomes a Tool

Decorative and architectural panels

Mirror 1060 sheets are widely used for decorative ceiling panels, interior wall cladding, column wraps, elevator decoration, and shopfitting. Designers use the reflective surface to visually expand space, guide light, and create a premium look without the weight and cost of stainless steel.

Lighting reflectors and luminaires

In commercial lighting, the mirror finish functions as an optical component. Reflector hoods, troffer reflectors, lamp housings, and LED panel back reflectors all benefit from 1060’s specular reflection, improving light efficiency and ensuring uniform brightness.

Solar and energy systems

Mirror 1060 aluminum appears in solar thermal collectors, parabolic reflectors, and concentration components where its high reflectivity helps concentrate or redirect solar radiation. The light weight enables larger reflector surfaces with less structural load, and the corrosion resistance supports outdoor use.

Signage, displays, and branding elements

Advertising panels, display stands, logos, and retail fixtures frequently rely on mirror 1060 to project a bright, high-end finish. The material is easy to route, laser cut, and bend into complex shapes while maintaining a clean, polished surface.

Equipment housings and panels

In equipment cabinets, control panels, and decorative machine covers, 1060 H112 mirror sheets offer functional benefits (corrosion resistance, easy cleaning) while giving devices a modern and professional appearance.

Transport and interior trim

Although not a structural alloy for heavy load-bearing parts, 1060 mirror sheets can be used for interior decorative trims in vehicles, trains, ships, and specialty transport equipment, particularly where reflective accents and low weight are desired.

Technical Parameters and Typical Specifications

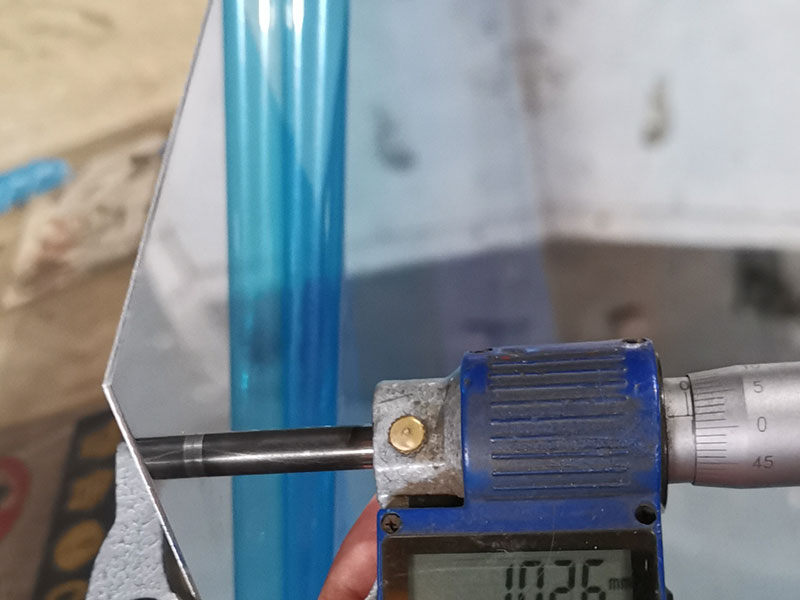

While exact values can vary by supplier and standard, 1060 H112 mirror finish aluminum sheets and plates commonly follow parameters similar to the ranges below.

Dimensional range

- Thickness: approximately 0.2 mm up to around 6.0 mm for sheets; thicker plates may be available on request

- Width: often from 500 mm to 2000 mm, with customized sizes for large panels or specific equipment requirements

- Length: standard stock lengths (such as 1000 mm–6000 mm) or cut-to-size services

Surface grades

Mirror finish can range from standard bright to high-specular mirror. Some suppliers define grades like:

- Standard mirror

- High brightness mirror

- Super mirror or specular mirror, depending on reflectivity percentage and visual clarity

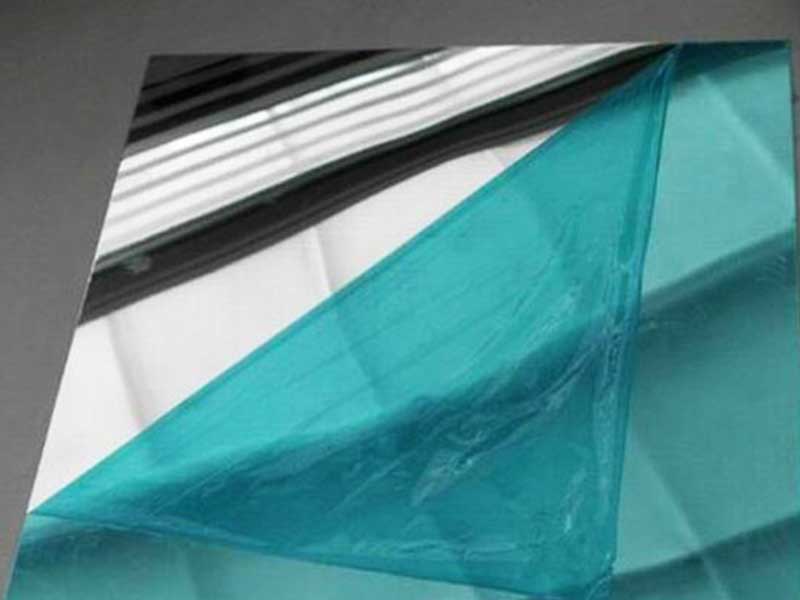

Surface protection

To preserve the reflective surface during processing, sheets are typically supplied with:

- PE or PVC protective film on one or both sides

- Optional paper interleaving for high-end mirror grades

Mechanical Properties in H112 Temper

Due to the nature of the H112 temper, mechanical properties are controlled but not heavily strengthened. Typical values (indicative only) may include:

- Tensile strength: roughly 60–100 MPa

- Yield strength: often around 30–70 MPa

- Elongation (A50): around 20% or higher, depending on thickness

These figures highlight excellent ductility and formability, which directly supports bending, forming, and embossing of mirror surfaces without excessive risk of cracking or orange-peel effects when processing conditions are well managed.

Chemical Composition of 1060 Aluminum Alloy

A representative chemical composition for 1060 plate and sheet is:

| Element | Content (wt. %) |

|---|---|

| Al | ≥ 99.60 |

| Si | ≤ 0.25 |

| Fe | ≤ 0.35 |

| Cu | ≤ 0.05 |

| Mn | ≤ 0.03 |

| Mg | ≤ 0.03 |

| Zn | ≤ 0.05 |

| Ti | ≤ 0.03 |

| Others (each) | ≤ 0.03 |

| Others (total) | ≤ 0.10 |

The dominance of aluminum in the composition directly supports high reflectivity, electrical and thermal conductivity, and corrosion resistance. Minimal alloying elements also help ensure reliable anodizing and consistent surface color if additional finishing is applied.

Implementation Standards and Quality Control

For sheets and plates, 1060 H112 mirror finish products are often manufactured and inspected in accordance with standards such as:

- ASTM B209 for aluminum and aluminum-alloy sheet and plate

- EN 485 / EN 573 series for wrought aluminum products and chemical composition

- GB/T standards in some markets for mirror aluminum sheet specifications

standard-related controls focus on:

- Chemical composition compliance

- Dimensional tolerance (thickness, flatness, width, length)

- Mechanical property verification for the H112 temper

- Surface quality: absence of rolling marks, scratches, water stains, oxidation spots, and inclusions visible on the mirror surface

Mirror finish aluminum is as much about surface control as it is about bulk material properties. Serious suppliers combine alloy control, rolling technology, polishing or bright-rolling processes, and strict packaging to deliver a consistently clean and uniform mirror appearance.

Choosing 1060 H112 Mirror Aluminum for Your Application

When evaluating whether 1060 H112 mirror finish sheets and plates are suitable for a project, it helps to focus on a few core questions:

- Is high reflectivity or decorative brightness central to the design?

- Are conductivity and light weight important, while ultra-high strength is not critical?

- Will the parts be formed, bent, or embossed, requiring good ductility?

- Is corrosion resistance in indoor or mild outdoor environments sufficient?

If the answer is yes to these points, 1060 H112 mirror aluminum is often a very efficient choice, balancing cost, processability, and appearance.

By its alloy purity, temper characteristics, implementation standards, and real-world performance in reflective and decorative functions, you can specify 1060 H112 mirror finish aluminum sheets and plates with confidence, aligning both technical requirements and visual design goals.

https://www.aluminumplate.net/a/1060-h112-mirror-finish-aluminum-sheets-plates.html