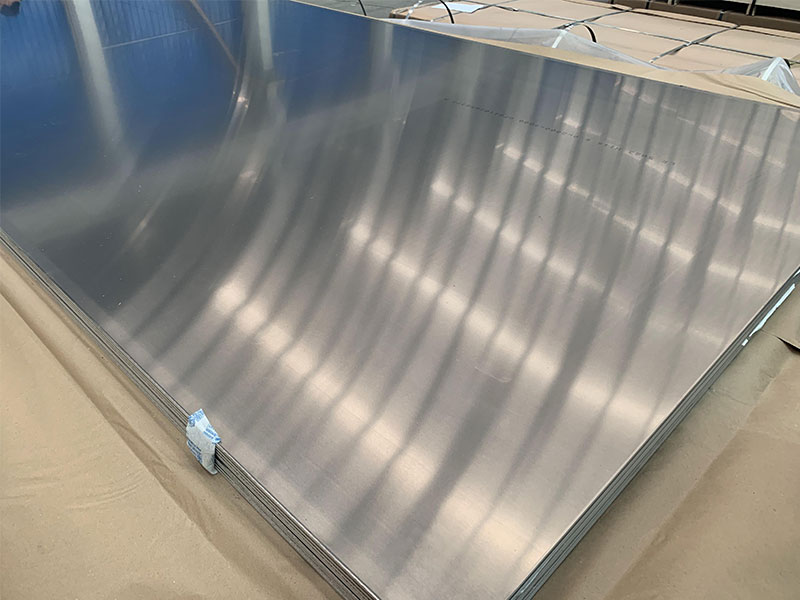

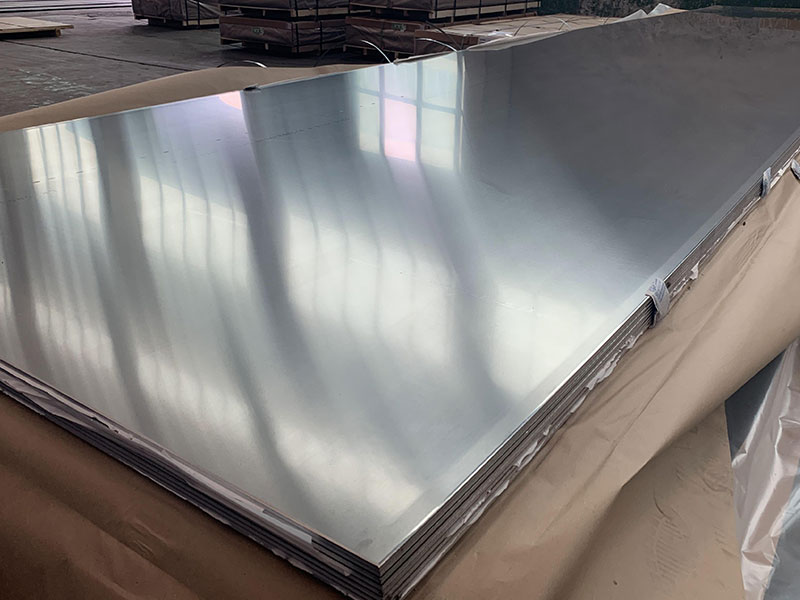

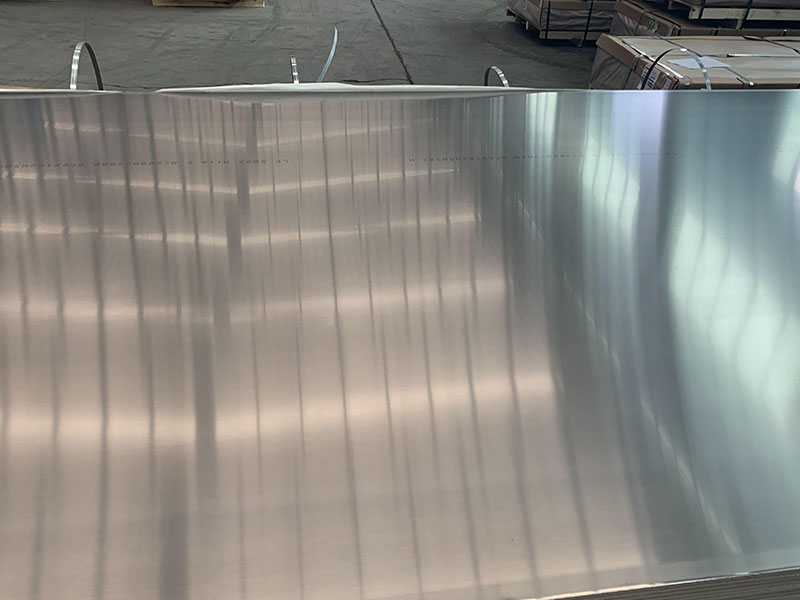

5052 5754 5083 marine aluminum sheet

When it comes to constructing robust, lightweight, and corrosion-resistant marine structures, aluminum alloys have long been trusted as premier materials. Among these, 5052, 5754, and 5083 marine aluminum sheets is know for their distinctive properties and broad utility. these alloys from the perspective of their functional advantages and tailored applications provides an insightful angle beyond standard material specifications.

Why Marine Aluminum Sheets Matter: The Fundamentals

Marine aluminum sheets serve as the backbone of many sea-facing structures and vessels, including ship hulls, decks, pontoons, and offshore platforms. What makes aluminum, especially these particular alloys, indispensable, is the combination of light weight, strength, excellent corrosion resistance, and good formability, enabling more durable, fuel-efficient, and easy-to-maintain marine environments.

Navigating the Three Alloys: 5052, 5754, and 5083

Although related, the 5052, 5754, and 5083 alloys offer nuanced variabilities that directly impact performance in marine settings. By viewing these sheets from a “function-first” perspective—rather than purely metallurgical specs—we gain real-world insight into material selection depending on functional demands.

1. 5052 Marine Aluminum Sheet: The Corrosion Defender

Core Characteristics:

- Medium strength (Yield strength ~215 MPa, tensile strength 228-290 MPa)

- Exceptional corrosion resistance, especially in saltwater/acidic environments

- Superior weldability with minimal risk of cracking

- Excellent fatigue resistance and moderate formability

Functional Benefits:

5052-sheet excels as the ideal cladding or external skin on boats and marine vessels where exposure to seawater is relentless. Its strength isn’t the highest but pairs superbly with its corrosion defenses and the ability to be bent and formed for hull plating, water-tight bulkheads, or lightweight decks. One can think of 5052 sheets as the “immune system” against the harsh naval elements — preventing oxidation and structural compromises over years without extensive maintenance.

Applications:

- Small recreational boats and pontoons

- Yacht superstructures with expose skins and non-structural parts

- Fuel tanks and pipes needing sealing from moisture infiltration

- Components requiring deep drawing or complex bending

2. 5754 Marine Aluminum Sheet: The Balanced Performer

Core Characteristics:

- Yield strength around 200-250 MPa (enhanced over 5052 in some tempers)

- Improved creep resistance at elevated temperatures (~80-100 °C)

- Good corrosion resistance with an edge toward thicker structural parts

- Excellent formability for sheet metal processes

Functional Benefits:

If 5052 is corrosion-centric and formability-friendly, 5754 tilts toward slightly higher strength with exceptional manufacturability. It acts as the structural intermediary between high-performance demanding operations and easier machining, offering versatility when moderate load-bearing actions are involved. Its temper variants allow marine fabricators to adjust toughness or ductility as projects demand.

Applications:

- Medium-duty marine decking and superstructures bearing environmental stress

- Reinforced sheet objects—consoles, storage lockers within decks

- Interiors of vessels requiring corrosion-resistant isothermal barriers

- Primary maritime equipment such as latches, frames, and brackets

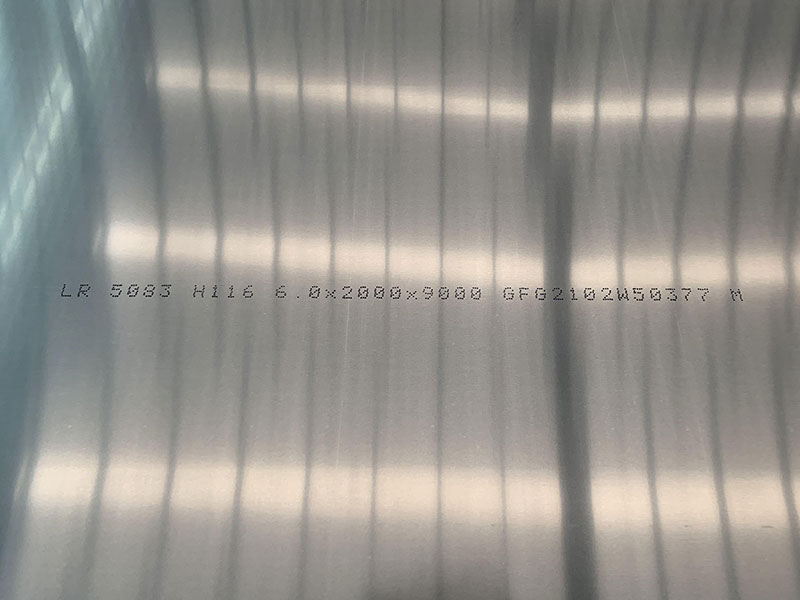

3. 5083 Marine Aluminum Sheet: The Heavy-Duty Champion

Core Characteristics:

- High yield strength (~215 to 290 MPa) and tensile strength (317-350 MPa)

- Outstanding corrosion resistance to seawater and industrial environments

- High fatigue strength and excellent weldability with AN-near performance

- Resistant to stress cracking degradation and good low-temperature toughness

Functional Benefits:

5083 marine aluminum occupies the top tier of strength and resilience among non-heat-treatable marine grade alloys. This material directly contributes to enhanced vessel safety and longevity where impact resistance, mechanical load, and harsh environmental exposure are highest. Beyond any other, 5083 inhibits stress-related degradation found within aggressive marine conditions — the “workhorse”/aluminum titan effect within demanding maritime structures.

Applications:

- Major hull spaces and deep load-bearing structural supports

- Naval vessels, freight carriers, offshore rigs with high corrosion fatigue zones

- Vehicle decks requiring crash/domain impact absorption abilities

- Bulkheads and armored marine components subjected to severe stress

The Technical Symbiosis with Marine Engineering: Why These Sheets Matter

All three alloys bring strength and seawater resistance to the forefront, but it’s their gradation in fabrication ease, adaptability, and robustness tailored to function and application that defines strategic choices in marine construction. Notably:

- The choose-your-function model: 5052 for lightweight and uncomplicated outer ship layers; 5754 when hybridization between durable structure and moderate shaping is needed; and 5083 when demands skew toward heavy use, requiring severe mechanical or environmental endurance.

- Their corrosion resistance respects the laws of alloying, where magnesium additions (up to ~5% in 5083 and 5754) accent strength, and minute additions of chromium fortify surface integrity without impairing ductility.

- Efficient weldability minimizes complications in joining, essential in modern fabrication lines maintaining tight timelines while maximizing quality.

https://www.aluminumplate.net/a/5052-5754-5083-marine-aluminum-sheet.html