1060 marine aluminium alloy sheet plate

1060 marine aluminium alloy sheet plate is a high‑purity, non‑heat‑treatable aluminium product designed for applications where excellent corrosion resistance, formability, and cost‑effectiveness are more important than very high strength. With a minimum aluminium content of 99.6%, 1060 alloy is widely used in shipbuilding, marine outfitting, and auxiliary marine systems, especially in non‑structural or lightly loaded components.

1060 belongs to the 1xxx series of commercially pure aluminium alloys. It is characterized by:

- Very high aluminium content (≥ 99.6%)

- Excellent corrosion resistance in marine and industrial atmospheres

- Outstanding formability and deep‑draw capability

- Good weldability and brazability

- High thermal and electrical conductivity

- Low mechanical strength compared with 5xxx or 6xxx marine alloys

Because of these properties, 1060 is typically selected for marine environments where corrosion resistance and manufacturability are critical, but high structural strength is not required.

2. Chemical Composition of 1060 Alloy

Typical chemical composition limits for 1060 aluminium (mass fraction, %):

| Element | Typical Range (%) | Notes |

|---|---|---|

| Al | ≥ 99.60 | Balance, high‑purity aluminium |

| Si | ≤ 0.25 | Impurity, affects strength/forming |

| Fe | ≤ 0.35 | Impurity, may slightly harden alloy |

| Cu | ≤ 0.05 | Kept low to preserve corrosion resistance |

| Mn | ≤ 0.03 | Trace only |

| Mg | ≤ 0.03 | Trace only |

| Zn | ≤ 0.05 | Trace only |

| Ti | ≤ 0.03 | Grain refiner (trace) |

| Others (each) | ≤ 0.03 | Minor residual elements |

| Others (total) | ≤ 0.10 |

Note: Actual composition may vary slightly depending on standard (e.g., ASTM, EN, GB/T) and manufacturer, but always maintains ≥ 99.6% Al.

3. Features and Benefits

3.1 Corrosion Resistance in Marine Environments

- Excellent resistance to seawater spray and marine atmosphere due to the natural, dense oxide film on high‑purity aluminium.

- Well suited for above‑waterline and indirect seawater contact applications, especially when combined with anodizing or coating.

- Low copper content minimizes risk of pitting and galvanic corrosion.

3.2 Formability and Fabrication

- Extremely ductile and soft, allowing:

- Deep drawing

- Bending with small radii

- Complex stamping and spinning

- Ideal for fabricated parts such as covers, fairings, housings, and lining plates.

- Low spring‑back makes it easy to achieve accurate formed shapes.

3.3 Weldability and Joining

- Excellent weldability with common processes:

- TIG (GTAW)

- MIG (GMAW)

- Resistance welding

- Can also be brazed and soldered; often used as cladding material.

- Low risk of hot cracking because of near‑pure composition and absence of strong alloying elements.

3.4 Thermal and Electrical Conductivity

- Very high thermal conductivity, typically around 220–235 W/m·K.

- High electrical conductivity, often > 55% IACS.

- Beneficial where heat dissipation or electrical continuity is required in marine systems (e.g., heat shields, busbars in shipboard power).

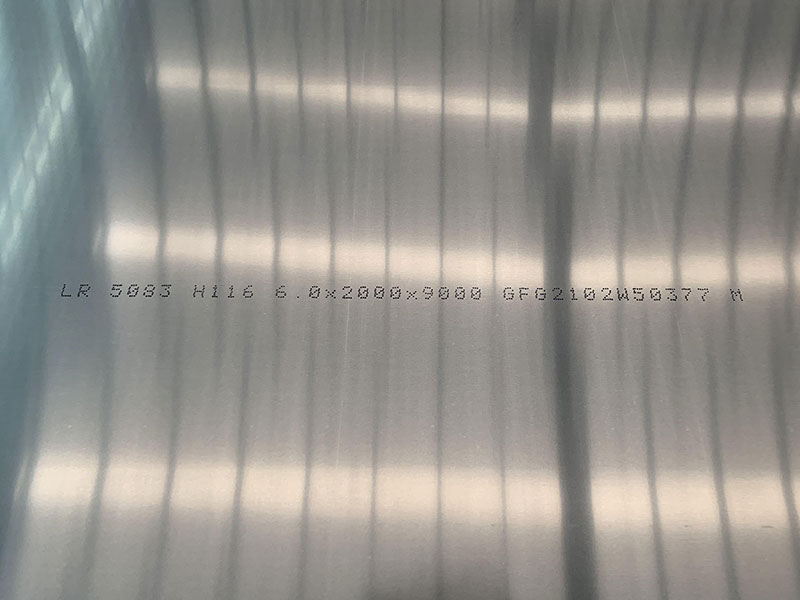

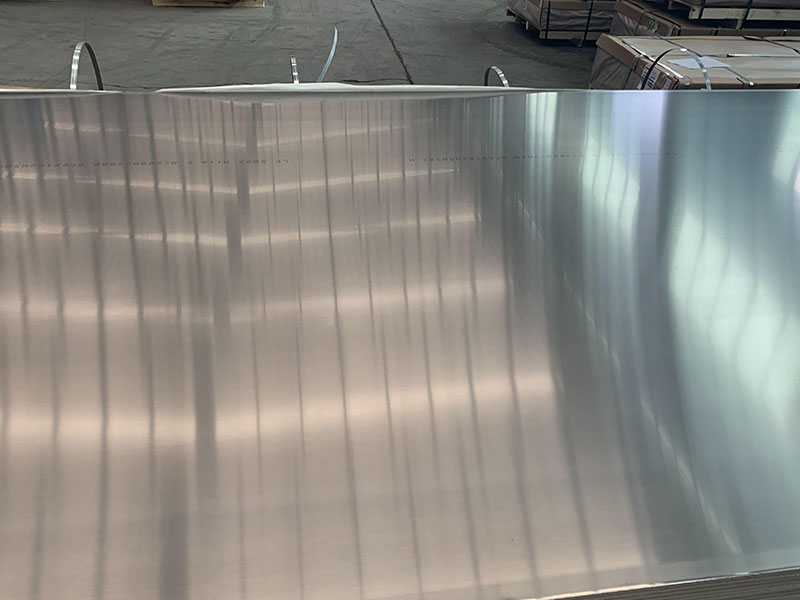

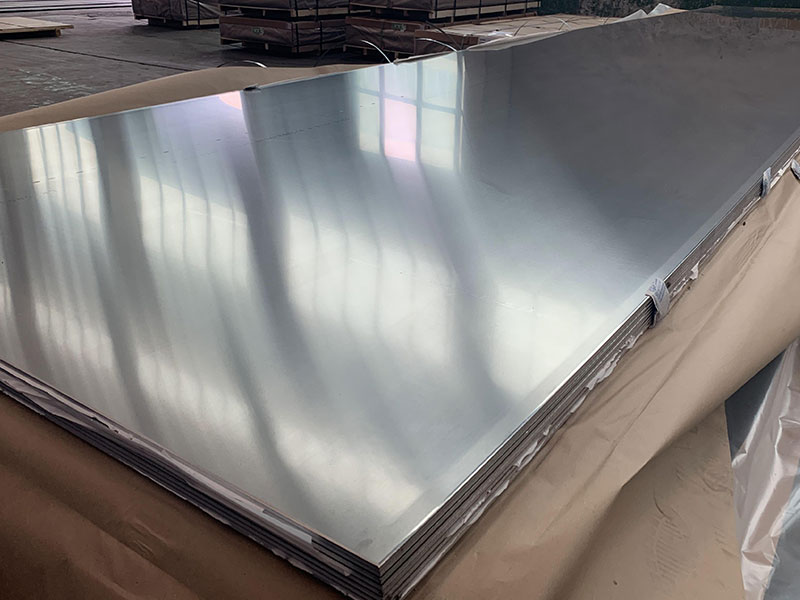

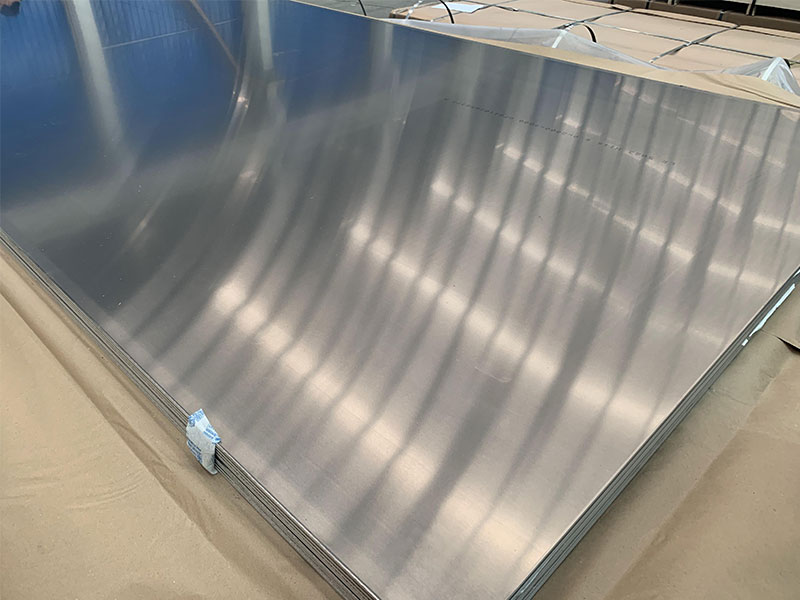

3.5 Surface Quality and Appearance

- Smooth, bright surface available with mill‑finish or brushed finishes.

- Very suitable for anodizing, painting, or anti‑corrosion coatings.

- Good choice for visible panels, decorative trim, and interior marine applications where appearance matters.

4. Mechanical Properties (Typical)

Typical room‑temperature mechanical properties for 1060 marine aluminium sheet/plate (nominal values for reference):

| Temper | Yield Strength Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation A50 (%) | Typical HV (Vickers) |

|---|---|---|---|---|

| O (Annealed) | 20–30 | 60–95 | 25–35 | 18–28 |

| H14 (Half‑hard) | 45–65 | 95–125 | 10–18 | 32–45 |

| H24 (Quarter‑hard) | 35–55 | 85–115 | 14–22 | 28–40 |

Values are indicative and depend on thickness and standard. For design, always refer to mill certificates and relevant codes.

Because its strength is modest, 1060 is rarely used as a primary load‑bearing structural plate in ship hulls; higher‑strength 5xxx series (e.g., 5083, 5086) are preferred for those applications. 1060 is more suited to secondary structures and non‑structural components.

5. Technical Specifications

Typical supply range for 1060 marine aluminium sheet/plate:

| Parameter | Typical Range / Option |

|---|---|

| Temper | O, H12, H14, H16, H18, H22, H24, H26, H32 (varies by supplier) |

| Thickness (sheet) | 0.3 – 6.0 mm |

| Thickness (plate) | 6.0 – 50 mm (or customized) |

| Width | 500 – 2500 mm (common: 1000 / 1220 / 1500 / 2000 mm) |

| Length | 1000 – 12000 mm (or custom cut‑to‑length) |

| Surface finish | Mill finish, brushed, embossed, anodized, coated |

| Standard | ASTM B209, EN 485/573, GB/T 3880, etc. |

| Edge condition | Mill edge, slit edge |

| Flatness | Controlled as per relevant standard or order |

Tight dimensional tolerances and good flatness can be achieved via hot rolling + cold rolling + tension leveling processes.

6. Performance in Marine Applications

6.1 Corrosion and Durability

- Performs well in humid, saline, and industrial atmospheres when surfaces are kept clean and protected.

- For long‑term direct seawater immersion or heavily loaded structural parts, 5xxx series alloys are usually superior, but 1060 still offers:

- Good resistance to atmospheric and splash‑zone exposure

- Stable oxide film and low corrosion rate

- Good compatibility with marine paints, primers, and anodic coatings

6.2 Fabrication Performance

- Cold forming: can be formed at room temperature into complex geometries with minimal cracking risk.

- Machining: relatively soft, so can gum up tools; requires sharp tooling and correct cutting parameters.

- Welding:

- Filler wires such as 1100 can be used for matching purity.

- Distortion control is important due to low stiffness and high thermal conductivity.

6.3 Thermal Performance

Typical physical properties:

| Property | Typical Value |

|---|---|

| Density (20 °C) | ~2.70 g/cm³ |

| Melting range | 645–660 °C |

| Thermal conductivity | ~220–235 W/m·K |

| Electrical conductivity | ~34–36 MS/m (~55–58% IACS) |

| Coefficient of thermal expansion (20–100 °C) | ~23.6 × 10⁻⁶ /K |

These properties make 1060 attractive for heat dissipation plates, shields, and conductive components in marine equipment.

7. Typical Marine and Offshore Applications

Because of its balance of cost, formability, and corrosion resistance, 1060 marine aluminium sheet and plate is widely used in:

7.1 Shipbuilding and Boatbuilding (Non‑Structural)

- Interior wall and ceiling panels

- Cabin linings and decorative panels

- Doors, window frames, and hatch covers (non‑load‑bearing parts)

- Storage cabinets, lockers, and furniture components

- Lightweight partitions and enclosures

7.2 Marine Outfitting and Equipment

- Instrument and electrical enclosures

- Cable trays, busbars, and junction box plates

- HVAC ducts, ventilation louvers, and air‑conditioning panels

- Pump covers, protective shields, and equipment guards

- Tank covers and access panels (not pressure‑critical)

7.3 Offshore and Port Infrastructure

- Cladding for control rooms and shelters

- Non‑load‑bearing facade and panel systems

- Sunshades, rain covers, and canopies

- Signage, information boards, and safety plates

7.4 Auxiliary Marine Systems

- Heat sink plates for power electronics and navigation systems

- Reflective panels in lighting and signaling units

- Sound insulation facings (as carrier sheets for insulation materials)

In all these applications, design must account for the relatively low strength of 1060; where higher loads are involved, use thicker sections, additional stiffeners, or select higher‑strength alloys for critical parts.

8. Advantages Compared with Other Marine Alloys

| Aspect | 1060 Alloy | Typical 5xxx Alloy (e.g., 5083) |

|---|---|---|

| Strength | Low | Medium to high |

| Formability | Excellent | Good to very good |

| Corrosion resistance | Excellent in atmosphere, good in splash | Excellent including immersion |

| Weldability | Excellent | Excellent |

| Cost | Lower (high‑purity, less alloying) | Higher (Mg‑alloyed) |

| Thermal conductivity | Higher | Slightly lower |

| Typical use | Non‑structural, interior/outfitting | Hull, decks, structural components |

For many marine customers, 1060 is an economical complement to 5xxx series alloys: 5xxx for structural and hull components, and 1060 for cladding, interiors, covers, and systems where formability and appearance dominate.

9. Selection Guidelines for Customers

When considering 1060 marine aluminium sheet plate, keep these points in mind:

Check load requirements

- Use 1060 mainly where strength demands are low to moderate.

- For primary structures or highly stressed zones, consider 5083/5086 or similar.

Consider forming complexity

- For deep‑drawn or highly contoured parts, 1060 (especially in O temper) provides outstanding formability.

Corrosion protection strategy

- For harsh marine environments, combine 1060 with anodizing, painting, or appropriate coatings for extended service life.

Thickness and stiffness

- If stiffness is important, you may need increased thickness or structural stiffeners because of the alloy’s low yield strength.

Compatibility with other materials

- Pay attention to galvanic corrosion when connecting 1060 to steels or copper‑rich alloys; use insulating gaskets, sealants, or coatings.

1060 marine aluminium alloy sheet plate offers a powerful combination of high purity, excellent corrosion resistance, exceptional formability, and cost‑effectiveness, making it a smart choice for a wide range of non‑structural and lightly loaded marine components.

By its properties and limitations—particularly its relatively low strength—customers can deploy 1060 strategically in shipbuilding, offshore platforms, and port facilities to achieve lightweight construction, simplified fabrication, and reliable corrosion performance at an attractive cost.

https://www.aluminumplate.net/a/1060-marine-aluminium-alloy-sheet-plate.html