Embossed aluminum sheet 1.0mm 1.5mm 2mm 3mm 4mm H14

Embossed aluminum sheets, especially those graded H14 and available in thicknesses of 1.0mm, 1.5mm, 2mm, 3mm, and 4mm, represent a remarkable fusion of form and function in the realm of metal fabrication. Offering a balance between aesthetic appeal and structural performance, these sheets have become indispensable across multiple industries.

Embossed Aluminum Sheets and H14 Temper Grade

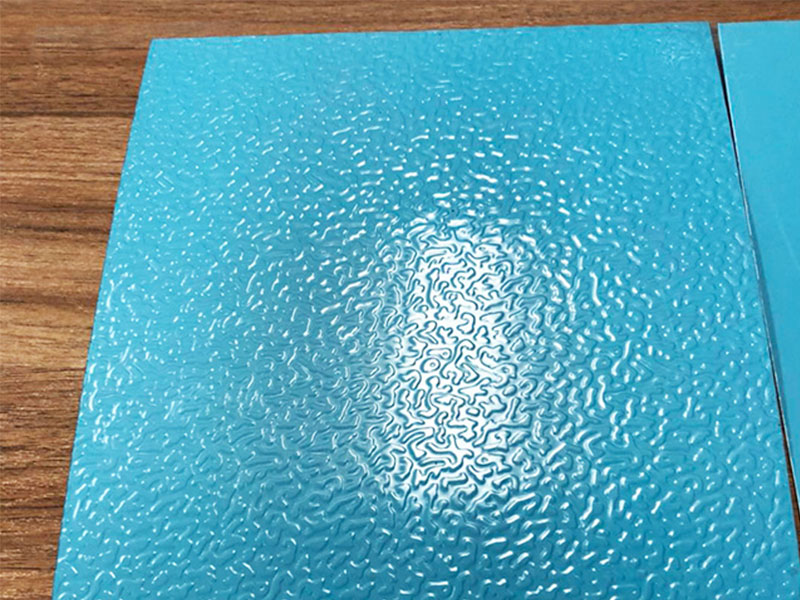

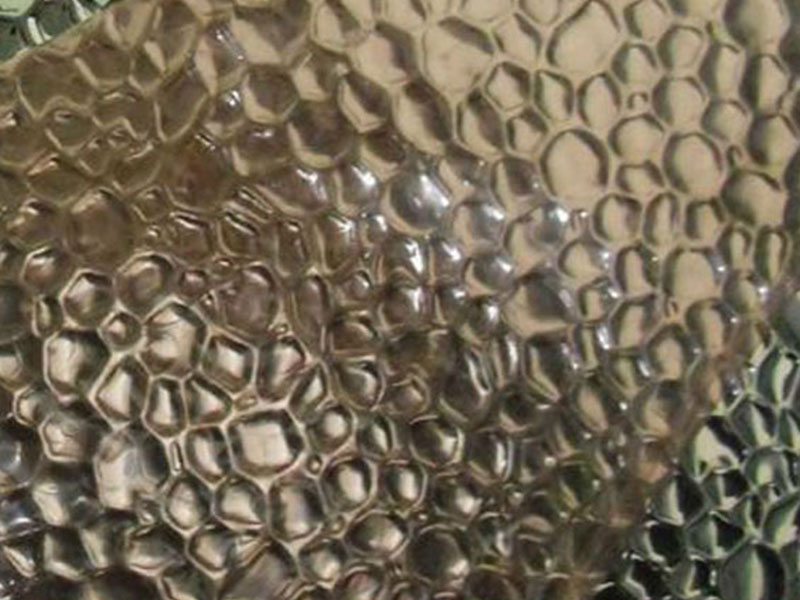

Embossed aluminum sheets undergo a rolling process that imprints a decorative or textured pattern onto the metal surface. This embossing enhances surface rigidity, improves visual appeal, and can deliver enhanced skid resistance where needed. The process induces localized plastic deformation, altering the sheet’s surface without compromising its core properties.

The embossed product detailed here adheres to the H14 temper classification. This temper means the aluminum alloy—commonly 3003, 3105, or sometimes 5052—is strain-hardened or cold-worked to a mid-hard stage corresponding to roughly 1/2 hard. Such tempering enhances mechanical strength and yield without jeopardizing formability. This balance is vital for both fabrication efficiency and end-use durability.

Thickness Variants: Why Thickness Matters

The available thicknesses—1.0mm, 1.5mm, 2mm, 3mm, and 4mm—offer significant variation in mechanical behavior, load-bearing capacity, and finish versatility.

1.0mm Thickness: Best for applications demanding lightweight and formability such as decorative panels, signage backing, and vapor barriers. The reduced thickness allows easier bending and stamping with modest strength.

1.5mm and 2.0mm Thickness: Serving as a middle ground, these sheets balance increased strength and moderate weight. Applications often include locker doors, HVAC duct lids, or flooring surfaces where higher rigidity is crucial but portability remains favorable.

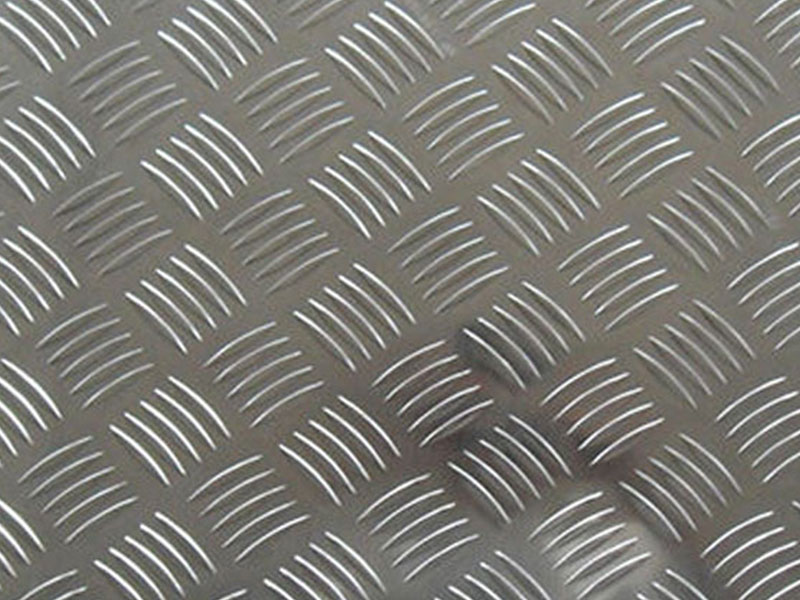

3.0mm and 4.0mm Thickness: Represent high-strength, durable options, essential in infrastructure elements or transportation components exposed to heavy wear, vibration, and impact forces. Examples include stair treads, vehicle panels, and industrial walkways. Their embossing significantly improves both skid resistance and structural stiffness.

Functional Advantages of Embossed Aluminum Sheets

Enhanced Strength-to-Weight Ratio: Embossing naturally increases the sheet’s stiffness by introducing a three-dimensional texture, thus enabling thinner gauges to replace heavier flat sheets without sacrificing structural integrity.

Improved Anti-Slip Properties: Especially vital in flooring and industrial walkways, embossed patterns reduce slip-related hazards without requiring external treatments.

Aesthetic Flexibility and Corrosion Resistance: The visually appealing patterns contribute to modern architectural cladding, elevators, and interior design elements. Coupled with aluminum’s natural oxide film, embossed sheets deliver corrosion resistance in outdoor and humid environments.

Energy Efficiency and Thermal Insulation: Some embossed sheets facilitate air circulation or reflectivity improvements where subtle ventilation or radiant barriers are necessary.

Applications Spanning Industries

The interplay of thickness and H14 temper quality paves the way for a multitude of usages:

Construction & Architecture: Wall cladding, ceiling panels, and decorative facades benefit from strong yet lightweight, rust-resistant surfaces with artistic dimension.

Transportation: Bus and truck bodies, aircargo floor panels, and fridges count on the balance of impact resistance and anti-slip embossing combined with weight savings vital for fuel economy.

Industrial Manufacturing: Equipment plating, machine guards, and clean-room interiors enjoy increased sheet toughness and the easy-to-clean robust embossed surface texture.

Furniture & Consumer Goods: Appliance backing, locker doors, and shelving insert sheets use thin embossed aluminum sheets that combine strength, appearance, and corrosion protection.

Final Thoughts

An embossed aluminum sheet with thickness variations from 1.0mm up to 4.0mm, manufactured under the H14 temper grade, delivers tailored engineering benefits suited to their intended applications. The enhancements in mechanical strength due to cold working, combined with embossing’s contribution to structural rigidity and surface functionality, make these aluminum sheets standalone choices for architects, builders, and fabricators alike.

Harnessing the synergy of embossed patterning and optimized alloy tempering proves to be a versatile solution—balancing lightness, toughness, corrosion resistance, and design appeal in a competitively priced material ready to meet diverse industrial and commercial needs.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-10mm-15mm-2mm-3mm-4mm-h14.html