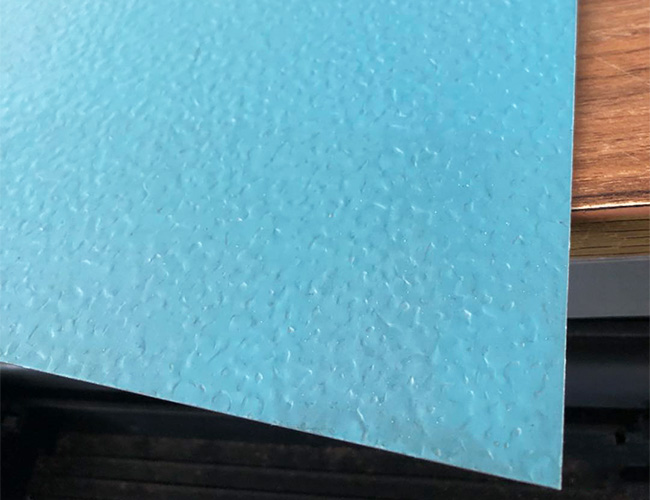

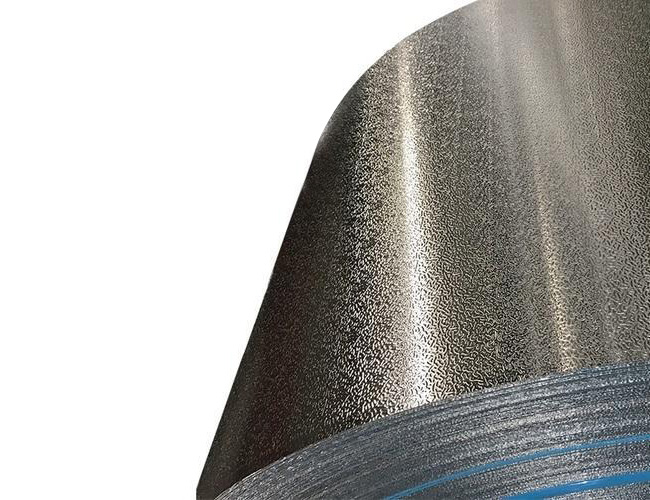

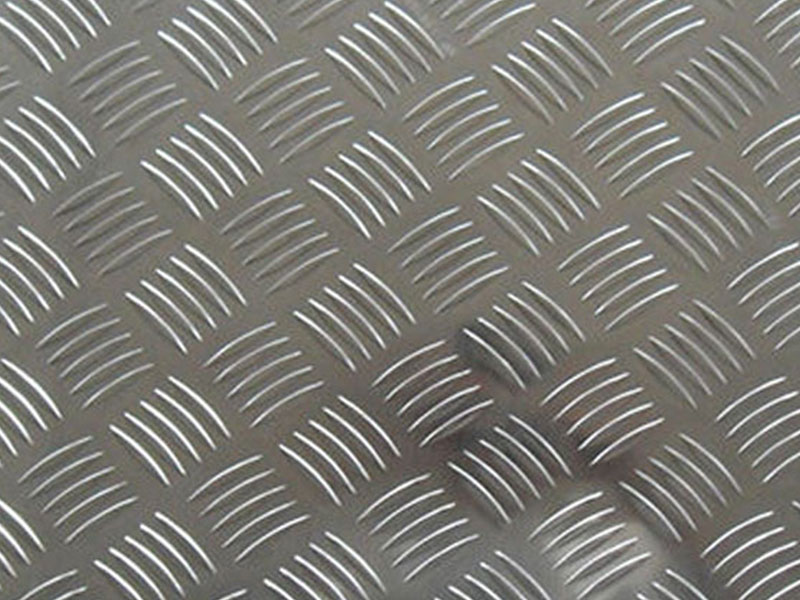

5circles 3003 1050 1060 H14 Aluminum Tread Diamond Plate Sheets For Floor

When it comes to safety, durability, and practicality in flooring solutions across industrial, commercial, and residential environments, 5circles’ Aluminum Tread Diamond Plate Sheets is know for their unique blend of strength, lightweight metal properties, and anti-slip surface design. In particular, the popular grades 3003, 1050, and 1060 Aluminum Tread Plates with H14 temper contribute significantly to environments demanding enhanced safety and corrosion resistance without compromising manageable handling and installation.

In t

Breaking Down the Grades: What Makes 3003, 1050, and 1060 Unique?

Each of these aluminum alloys listed in the 5circles product line encapsulates specific properties beneficial for floor applications:

3003 Aluminum Alloy: Known as a general-purpose alloy, it contains approximately 1.2% manganese, which improves its strength over pure aluminum while maintaining excellent corrosion resistance. This makes 3003 optimal for preventing wear under foot traffic and exposure to the elements.

1050 Aluminum Alloy: Characterized by very high aluminum purity (about 99.5%), 1050 offers exceptional workability and corrosion resistance but has comparatively lower mechanical strength. It's often chosen when electrical conductivity and flexibility are prioritized.

1060 Aluminum Alloy: Similar to 1050 but with an even higher aluminum content (~99.6%), 1060 provides extremely high corrosion resistance and is the industry standard for applications needing superior chemical purity, paired with lightweight characteristics.

H14 Temper: Harmonizing Strength and Flexibility for Flooring Use

The H14 temper designation is defined by the aluminum plate being strain-hardened to a specific degree, which means:

- Increased Yield Strength: Provides moderate strength that balances ductility and rigidity, imperative for floors enduring repetitive loads or footfalls.

- Good Workability: Despite hardening, the sheets retain ductsility allowing for bending and shaping during installation without cracking.

- Fatigue Resistance: A critical factor in flooring materials; H14 temper withstands repetitive strain and obstacles better than softer tempers.

Technically, the H14 temper is a half-hard condition in the “H1x” strain-hardened tempers, suitable for preventing excessive deflections and dents while allowing some material play — perfect for diamond tread plates functioning under occupational loads and impacts.

Functional Features and Parameters Important for Tread Plates on Floors

1. Slip Resistance:The signature diamond-shaped raised surface, also referred to as the “tread,” significantly increases friction between footwear and the plate surface, drastically reducing slipping accidents — pivotal in industrial and wet environments like factories, warehouses, and food processing plants.

2. Weight-to-Strength Ratio:Thanks to aluminum’s inherently low density (~2.7 g/cm³ compared to steel’s ~7.85 g/cm³), 5circles aluminum sheets enable easy transport and installation — critically reducing load on sub-floors and structural supports.

3. Corrosion Resistance:5circles combines excellent aluminum alloys that develop a natural oxide layer, rendering sheets corrosion resistant even in moisture-prone or mildly chemically aggressive environments.

Technical Chemical Composition Table (wt.%)

| Element | 3003 | 1050 (UNS A91050) | 1060 (UNS A91160) |

|---|---|---|---|

| Aluminum (Al) | Balance | ≥ 99.5 | ≥ 99.6 |

| Manganese (Mn) | 1.0 - 1.5 | ≤ 0.05 | ≤ 0.03 |

| Iron (Fe) | ≤ 0.7 | ≤ 0.4 | ≤ 0.35 |

| Copper (Cu) | ≤ 0.10 | ≤ 0.05 | ≤ 0.05 |

| Silicon (Si) | ≤ 0.6 | ≤ 0.25 | ≤ 0.15 |

| Zinc (Zn) | ≤ 0.10 | ≤ 0.10 | ≤ 0.05 |

| Titanium (Ti) | ≤ 0.05 | N/A | N/A |

| Other elements | ≤ 0.15 | N/A | N/A |

Note: Trace elemental variances ensure different alloy properties tailored toward strength (3003) or purity/corrosion performance (1050 and 1060).

Mechanical Property Highlights (H14 Temper)

| Property | 3003 H14 | 1050 H14 | 1060 H14 |

|---|---|---|---|

| Tensile Strength (MPa) | 131 - 210 | 90 - 125 | 95 - 130 |

| Yield Strength (MPa) | 72 - 135 | 35 - 70 | 40 - 75 |

| Elongation Percent (%) | 4 - 10 | 5 - 15 | 5 - 12 |

| Hardness (Brinell) | 40 - 55 HB | 20 - 35 HB | 25 - 40 HB |

These moderate-strength properties combined with excellent elongation make H14 plates versatile for floor usage demanding durability but not victims to brittle cracking.

Implementation Standards and Quality Criteria

5circles aluminum plates conform to the international and domestic standards assuring buyers high-quality, application-compliant tread plates:

- ASTM B632 – Standard specification for aluminum alloy, rolled plate/sheet, plate for general general mechanical uses and tread plate surfaces.

- ALMA/HH-1/MQ-F-558 – Emphasizing thickness consistency and embossing uniformity to maintain floor aesthetics and uniformity.

- JIS H4100 – Japanese Industrial Standard governing alloy compositions and mechanical performances.

Use in flooring pertained to workplaces demanding OSHA’s recommendations for anti-slip floor materials and compliance to fire retardation ratings in some commercial contexts.

Applications Real World Utility of 5circles Aluminum Tread Diamond Plates

- Industrial Walkways: Raised monarch diamond shapes protect labor forces from falls where oil or water lubrication occurs.

- Vehicle Flooring: Inside Eagles, buses, custom-built trucks where extra grip enhances cargo stability and worker safety.

- Sports and Recreational Surfaces: Non-slip on skatepark ramps, gym surfaces enhancing security for feet airflow.

- Marine Platforms: Anti-corrosive to saltwater seas, strengthening dock sidings and boat steps.

- Food Industry Flooring: Resists cleaning chemicals imparting safety in food prep and processing zones.

Why Choose 5circles?

Beyond standard function, 5circles excels by rigorously controlling sheet thickness, tread embossing dimension uniformity, chemical alloy content, and mechanical tempering processes, thus ensuring each sheet performs accurately per safety, installation, and longevity demands expected.

Furthermore, their aluminum plates prove highly recyclable and environmentally friendly, providing an increasingly vital selling point in sustainable construction and industrial maintenance campaigns.