Thin or Thick Aluminium Sheet 1070 for Construction

Aluminium Sheet 1070 is a highly pure aluminum product, prized in the construction industry for its excellent corrosion resistance, outstanding workability, and superior electrical and thermal conductivity. Available in a wide range of thicknesses, from thin to thick sheets, the 1070 variant is specially formulated for robustness and durability in structural applications, façades, cladding, roofing, and various architectural elements.

Chemical Composition

Aluminium Sheet 1070 falls within the Aluminum Association’s 1000-series alloys, often described as commercially pure aluminum with a minimum aluminum content of 99.7%. Below is the typical chemical composition emphasis according to ASTM B209 and EN 485-2 standards:

| Element | Content (%) |

|---|---|

| Aluminium (Al) | 99.7 min |

| Copper (Cu) | ≤0.05 |

| Iron (Fe) | ≤0.4 |

| Manganese (Mn) | ≤0.03 |

| Silicon (Si) | ≤0.05 |

| Zinc (Zn) | ≤0.05 |

| Titanium (Ti) | ≤0.03 |

| Others | ≤0.05 (each), ≤0.15 total |

The near-pure aluminum structure ensures excellent resistivity against corrosion and staining in outdoor environments.

Available Thickness and Dimensions

Whether your application demands a lightweight thin sheet for aesthetic cladding or a thick, robust sheet for structural reinforcements, 1070 aluminum sheets have you covered:

Thickness Range:

Thin Sheets: 0.2 mm to 1.0 mm

Medium Thickness: 1.0 mm to 3.0 mm

Thick Sheets: 3.0 mm to 6.0 mm (and higher upon request)

Standard Widths: 1000 mm, 1250 mm, 1500 mm, and custom sizes

Lengths: Up to 6000 mm or customized according to construction demands

The variability ensures precision fitment, minimal waste, and compatibility with automated fabrication equipment.

Tempering and Mechanical Properties

Aluminium 1070 is primarily supplied in different temper Conditions to balance between malleability and strength as mandated by architectural requirements.

| Temper Designation | Description | Typical Mechanical Properties (minimum) |

|---|---|---|

| O | Annealed (soft) | Tensile Strength: ≥40 MPa, Yield Strength: ≥18 MPa |

| H12 | Strain Hardened (quarter-hard) | Tensile Strength: ≥85 MPa, Yield Strength: ≥55 MPa |

| H14 | Strain Hardened (half-hard) | Tensile Strength: ≥115 MPa, Yield Strength: ≥95 MPa |

The O temper is widely preferred for applications that require high ductility and ease of fabrication, such as forming and bending for curved roof panels or complex cladding profiles. Cold-hardened tempers provide enhanced strength, durable against wind loads or minor structural stresses without compromising workability.

Standards and Implementation

Aluminium sheet 1070 products conform to major international standards, facilitating efficient design approvals and smooth regulatory compliance.

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- EN 485-2: Aluminium and aluminium alloys. Sheet, strip and plate. Mechanical properties

- JIS H4000: Aluminum and aluminum alloy sheet, plate

- ISO 6361: Wrought aluminum and aluminum alloy sheet, strip, and plate - Conditionally applies

These standards provide comprehensive guidance on chemical composition, mechanical hardness, dimensional tolerances, and finishing requirements, critical for high-quality architectural installations.

Advantages for Construction

- High Corrosion Resistance: Aluminum 1070's high purity offers natural passivation, ideal for outdoor façades and roofing exposed to varied climatic conditions.

- Lightweight: Even thick gauges maintain relatively low weight compared to steel or copper, easing transport and structural loading calculations.

- Excellent Workability: Easily formed, cut, welded and anodized, adjusted on-site as necessary with minimal special tooling needs.

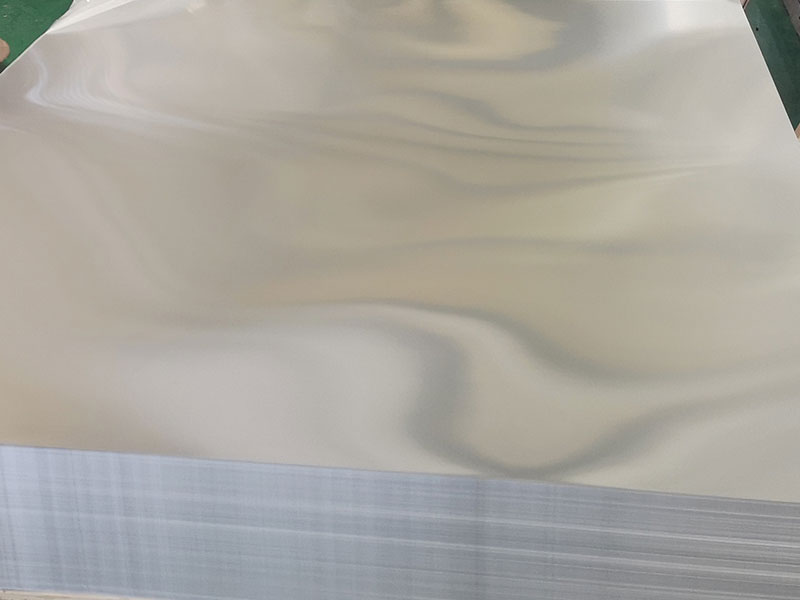

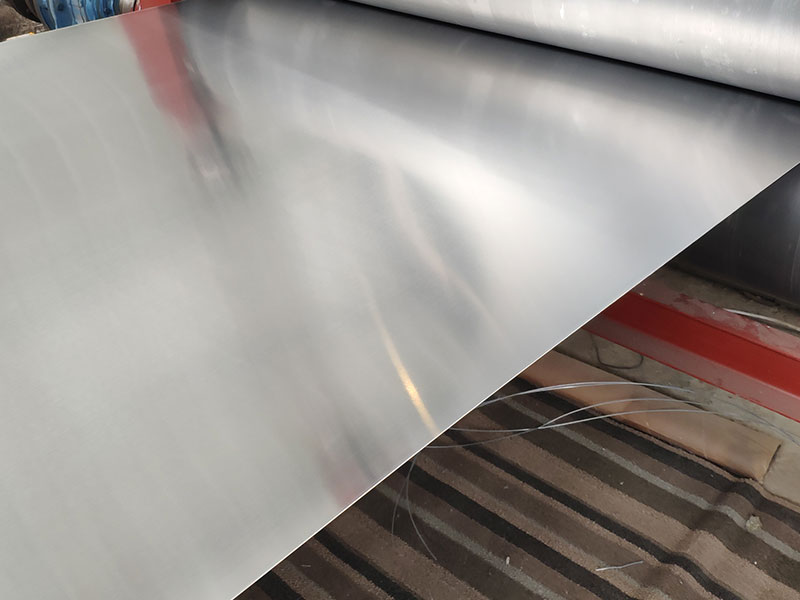

- Aesthetic Finish: Can be customized with reflective finishes, perforations or anodizing processes to enhance energy efficiency or aesthetic expression.

- Sustainability: Highly recyclable with minimal environmental footprint, promoting eco-friendly construction practices.

Typical Applications in Construction

- Exterior and interior architectural cladding

- Roofing panels requiring weather resistance and aesthetic metallic appearance

- Decorative ceiling tiles and ornamental fixtures

- Lightning and electrical component housings integrated on-site

- HVAC duct components benefitting from corrosion resistance and lightweight advantages

https://www.aluminumplate.net/a/thin-or-thick-aluminium-sheet-1070-for-construction.html