Aluminum mirror finished sheet

An aluminum mirror finished sheet is a premium, highly reflective aluminum product engineered to deliver a clean, bright "mirror" appearance while retaining aluminum's natural advantages: low weight, corrosion resistance, and excellent formability. Unlike glass mirrors, mirror-finished aluminum is shatter-resistant, easier to fabricate, and suitable for large-area panels, curved parts, and lightweight structures. It is widely used in architectural interiors, lighting reflectors, appliances, decorative panels, signage, and solar/thermal reflection systems.

Mirror finish is achieved through controlled rolling, polishing, bright annealing (for select alloys), and high-performance surface treatments. The end result is a sheet that is not only visually striking but also designed to perform in real manufacturing environments-cutting, bending, embossing, laminating, and bonding.

What "Mirror Finished" Really Means

Mirror-finished aluminum is defined less by a single process and more by an outcome: high specular reflectivity, consistent gloss, and low surface distortion. A well-produced mirror sheet offers:

- High reflectance for light management and decorative brilliance

- Uniform surface clarity with minimized waviness and roll marks

- Stable color tone across batches for consistent product appearance

- Compatibility with fabrication such as stamping, bending, and lamination

- Protective surface options that preserve reflectivity during handling and service

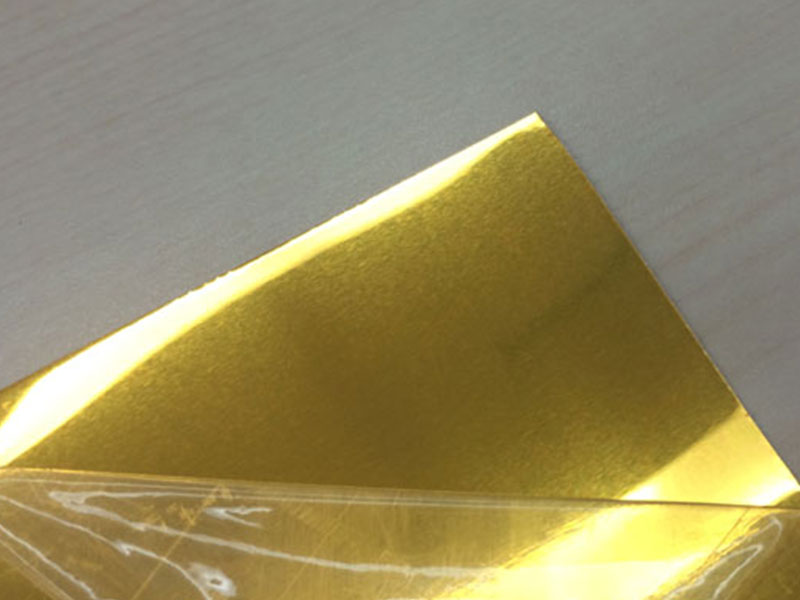

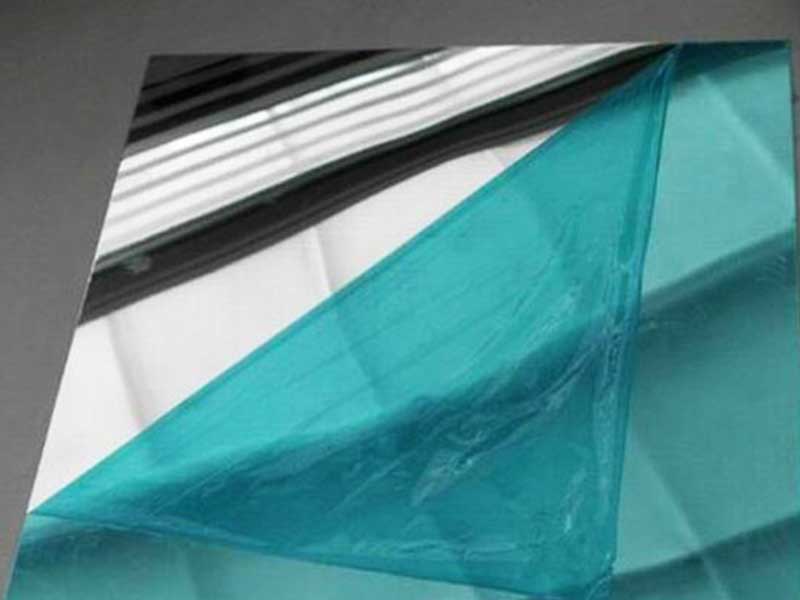

Many mirror sheets are supplied with a protective film to prevent scratches during fabrication and transport, and may also include anodized or coated surfaces to improve abrasion and corrosion resistance.

Features Customers Value

| Feature | What It Delivers | Typical Benefit in Use |

|---|---|---|

| High specular reflectivity | Strong mirror-like image quality | Brighter luminaires, premium decorative look |

| Lightweight | ~1/3 the density of steel | Easier installation, reduced structural load |

| Corrosion resistance | Natural oxide layer plus optional anodizing | Longer service life indoors and outdoors |

| Formability (alloy-dependent) | Bending and shaping with controlled springback | Curved trims, reflector geometries |

| Process-friendly surface | Works with cutting, punching, laser (with care) | Efficient fabrication and assembly |

| Shatter resistance | Metal substrate, not glass | Safer for public spaces and transport |

Common Alloys Used for Mirror Finished Sheet

Mirror finish can be produced on several aluminum alloy families. Selection typically balances reflectivity, formability, strength, and corrosion performance.

| Alloy | Temper (Typical) | Strength Level | Formability | Notes |

|---|---|---|---|---|

| 1050 / 1060 | O, H14, H24 | Low | Excellent | Very high reflectivity potential, ideal for reflectors and decoration |

| 1070 / 1085 | O, H14 | Low | Excellent | Higher purity, often chosen for optical reflectors |

| 3003 | H14, H24 | Medium | Good | Better strength than 1xxx, good general-purpose mirror sheet |

| 5052 | H32, H34 | Medium–High | Good | Strong corrosion resistance, suitable for harsher environments |

Typical Chemical Composition (Reference)

Actual composition varies by standard and supplier practice. Values below are common reference ranges used in commercial supply.

| Alloy | Al (min) | Si (max) | Fe (max) | Cu (max) | Mn (max) | Mg (max) | Zn (max) | Ti (max) |

|---|---|---|---|---|---|---|---|---|

| 1050 | 99.50 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 |

| 1060 | 99.60 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 |

| 3003 | Rem | 0.60 | 0.70 | 0.05–0.20 | 1.00–1.50 | 0.05 | 0.10 | 0.10 |

| 5052 | Rem | 0.25 | 0.40 | 0.10 | 0.10 | 2.20–2.80 | 0.10 | 0.15 |

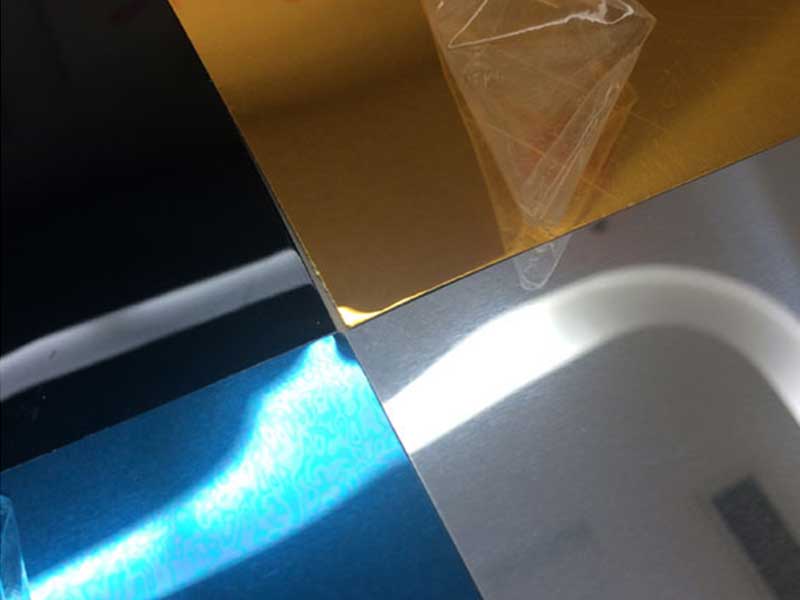

Surface Options and Performance Notes

The "mirror" look can be delivered with different surface constructions. Choosing the right one depends on whether you prioritize maximum reflectivity, scratch resistance, or outdoor durability.

| Surface Type | Appearance | Durability | Typical Uses |

|---|---|---|---|

| Bright polished mirror | Highest clarity, strong mirror image | Medium (scratch-sensitive) | Decorative interiors, display fixtures |

| Anodized mirror | Slightly toned, very clean | High (excellent wear/corrosion) | Architecture, elevators, premium trims |

| Coated mirror (PVD / lacquer) | Can be tinted or color-stabilized | High (depends on coating) | Signage, branded panels, appliances |

| Laminated / protected mirror | Mirror plus protective layer | High during processing | Mass production where handling marks are critical |

Technical Specifications (Typical Supply Range)

These are common ordering ranges; exact limits depend on mill capability and finishing route.

| Parameter | Typical Range / Options |

|---|---|

| Thickness | 0.3–3.0 mm (common), thicker available on request |

| Width | 500–1500 mm (common), wider possible by capability |

| Length | 1000–6000 mm (or coil supply) |

| Flatness | Controlled for panel applications; tighter flatness available |

| Protective film | PE film options: low/medium/high tack; single or double side |

| Surface finish | Mirror, super mirror, anodized mirror, coated mirror |

| Edge condition | Slit edge (coil), trimmed edge (sheet), deburred options |

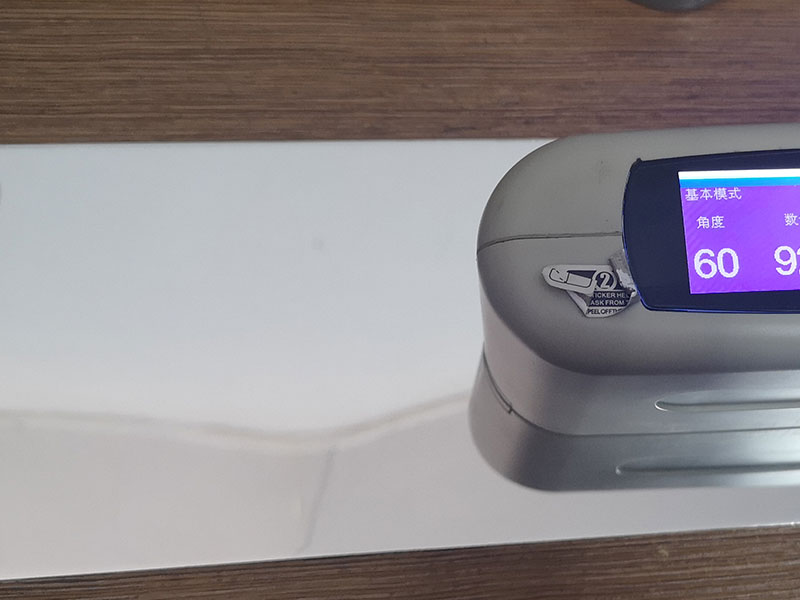

Reflectivity and Visual Quality (Typical Numerical Data)

Reflectivity depends on alloy purity, finish route, and surface protection. Values below are typical guidance ranges.

| Property | Typical Value |

|---|---|

| Total reflectance (visible) | ~75–90% (finish-dependent) |

| Specular reflectance (visible, 60°) | ~80–95% (high-grade mirror) |

| Gloss (60°) | Often > 800 GU for premium mirror finishes |

| Surface roughness Ra | Commonly 0.02–0.10 μm for mirror-grade surfaces |

When your application involves optical performance-such as luminaires or concentrators-request reflectance test data and define inspection criteria for surface waviness, haze, pinholes, and color consistency.

Applications: Where Mirror Finished Aluminum Shines

| Industry | Typical Application | Why Mirror Aluminum Fits |

|---|---|---|

| Lighting | Reflector cups, linear reflectors, lamp housings | Maximizes light efficiency and uniformity |

| Architecture & interiors | Wall panels, ceilings, trims, columns | Premium look with low weight and durability |

| Elevators | Door skins, cabin panels | High aesthetics, easy cleaning, impact resistance |

| Appliances | Decorative facias, interior reflectors | Consistent finish and manufacturability |

| Retail & display | Signboards, product backdrops, fixtures | Strong visual impact, easy fabrication |

| Transportation | Interior panels, decorative elements | Weight reduction and safer than glass |

| Solar & thermal | Reflective liners, concentrator components | High reflectance for energy capture/management |

Fabrication Guidelines (Practical Shop Notes)

| Process | Recommendation | Benefit |

|---|---|---|

| Cutting | Use clean tools; protect surface with film | Reduces scratching and edge burr marks |

| Bending | Prefer larger bend radii on harder tempers | Prevents micro-cracking and surface distortion |

| Stamping/Embossing | Verify finish after forming trials | Maintains mirror clarity on shaped parts |

| Bonding | Clean with suitable solvent; test adhesive compatibility | Strong bonds without staining |

| Anodized/coated handling | Avoid abrasive pads; use soft gloves | Preserves optical surface quality |

For demanding cosmetic parts, define acceptance criteria for surface defects under specified lighting, and keep protective film on until final assembly.

How to Specify the Right Product When Ordering

| What to Specify | Example |

|---|---|

| Alloy and temper | 1060-H14, 3003-H24, 5052-H32 |

| Thickness × width × length | 1.0 mm × 1250 mm × 2500 mm |

| Finish grade | Mirror / super mirror / anodized mirror |

| Surface protection | PE film, high tack, single-side |

| Visual standard | Limit haze, scratches, dents; inspection distance and lighting |

| Application environment | Indoor decorative, humid area, outdoor sheltered |

An aluminum mirror finished sheet combines high reflectivity and premium aesthetics with the practical advantages of aluminum: lightweight, corrosion resistance, and fabrication flexibility. By selecting the appropriate alloy, temper, and surface treatment-polished, anodized, or coated-you can tailor performance for everything from high-efficiency lighting to architectural panels and high-end appliance trims. For best results, specify not only size and alloy, but also finish grade, protection film, and visual inspection criteria to ensure consistent, production-ready quality.

https://www.aluminumplate.net/a/aluminum-mirror-finished-sheet.html