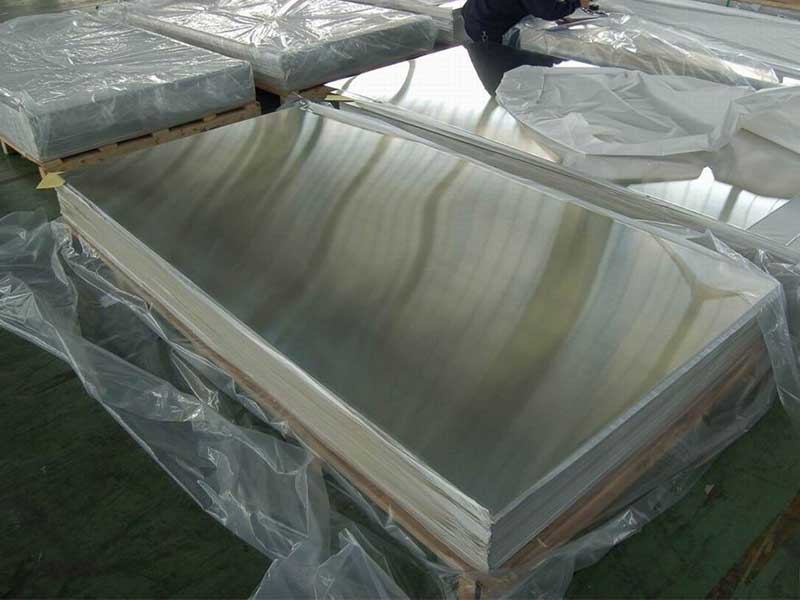

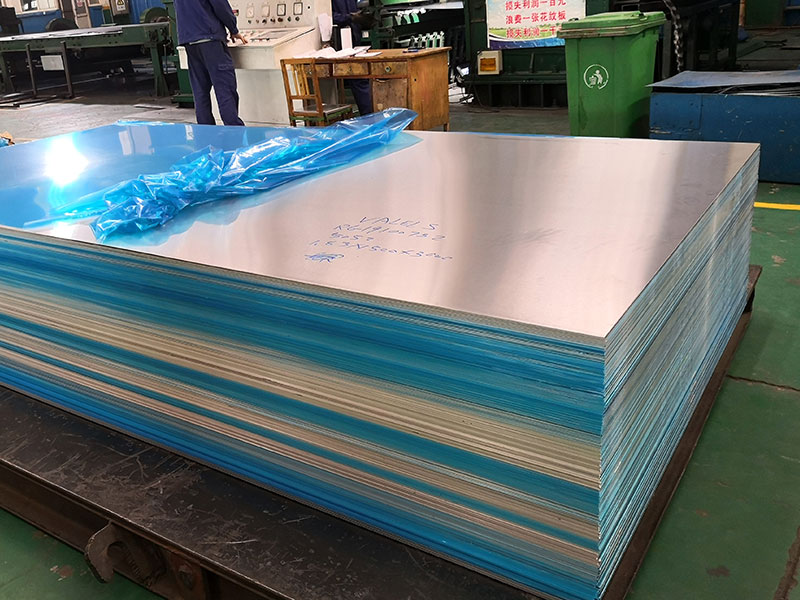

1100 h12 polished aluminium sheets

1100 H12 polished aluminum sheets are distinguished aluminum products widely recognized for their exceptional performance and versatility. Produced from the 1100 aluminum alloy, these sheets are characterized by their excellent corrosion resistance, high thermal conductivity, and distinctively polished surface. They find applications in diverse industries and projects, combining aesthetics with functionality.

Features

- High Corrosion Resistance: 1100 series aluminum offers excellent resistance to atmospheric corrosion, making it a reliable choice for applications exposed to moisture and other aggressive environments.

- Good Workability: Aluminum 1100 in the H12 temper allows for standard forming to be completed without difficulty, ensuring easy fabrication into various shapes and sizes.

- Aesthetic Appeal: The polished surface not only enhances the appearance but also contributes to low surface stress, minimizing the risk of surface imperfections.

- Thermal and Electrical Conductivity: With high thermal and electrical conductivity, these sheets are ideal for applications requiring heat dissipation and electrical components.

- Lightweight: Aluminum is lighter than steel and offers robust strength beneficial across a wide range of uses.

Applications

Due to its myriad advantages, 1100 H12 polished aluminum sheets are utilized in an array of applications, including:

- Architectural fabrications (curtains, domes).

- Automotive parts (engine components, trims).

- Interior and exterior lighting reflectors.

- Kitchen equipment (hoods, fryers).

- Chemical and food processing equipment.

Technical Specifications

| Property | Description |

|---|---|

| Material Type | Aluminum Alloy 1100-H12 |

| Thickness Range | 0.020" - 0.250" (0.5mm - 6.35mm) |

| Width Range | Up to 60" (1525mm) |

| Length Range | Custom sizes up to 240" (6096mm) |

| Temper | H12 (Strain-hardened) |

| Density | 2.70 g/cm³ |

| Melting Point | Approx. 660°C |

| Thermal Conductivity | 235 W/(m·K) |

| Electrical Conductivity | 60% IACS |

Chemical Composition

The chemical composition of 1100 H12 polished aluminum sheets is fundamental to defining its mechanical and chemical properties. The elements in the 1100 alloy include:

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | 99.0 min |

| Copper (Cu) | 0.05 - 0.20 |

| Iron (Fe) | 0.0 - 0.40 |

| Manganese (Mn) | 0.0 - 0.05 |

| Magnesium (Mg) | 0.0 - 0.05 |

| Silicon (Si) | 0.0 - 0.25 |

| Zinc (Zn) | 0.0 - 0.10 |

| Other (total) | 0.0 - 0.15 |

Alloy Tempering Conditions

The 'H' temper designation indicates that the material has undergone strain hardening with the second digit specified (in this case, 12) indicating the specific strength and IDs for intermediate levels of resistance to deformation.

- H12 specifies that dealing operations were performed and moderate recovery of strength has taken place whilst retaining some of the stamping characteristics – the solution enhances both performance and manufacturability.

1100 H12 polished aluminum sheets combine high efficiency, versatile applications, and aesthetic appeal into a single product. They contain excellent mechanical properties, ensuring consistent reliability across multiple operational environments. Widely usable in various industries, from architecture to automotive production, these polished sheets effectively balance both functionality and design aesthetics.

By the inherent material properties, chemical composition, and practical uses, engineers and manufacturers can make informed decisions when selecting aluminum sheets for their specific applications.

https://www.aluminumplate.net/a/1100-h12-polished-aluminium-sheets.html