Anodized aluminum sheet anodizing process

When considering the true potential of aluminum sheets in industrial and aesthetic applications, riveting strength, corrosion resistance, and attractive finishes are often the primary benefits attributed to anodized aluminum.

The Aluminum Canvas: Surface as a Foundation

Visualize the aluminum sheet as a blank canvas. Its natural state is smooth, lightweight, and corrosion-resistant to some degree, but it remains susceptible to scratches, wear, and the damaging effects of the environment. Anodizing transforms this blank canvas into an enduring, vibrant work of art — all through a careful and deliberate electrochemical process that engineers can exploit in creative ways.

Anodizing: More Than a Surface Coating

From a distinctive viewpoint, anodizing isn’t merely about adding a layer; it’s about initiating a fundamental transformation in the aluminum's surface chemistry. During this process, an oxide film forms directly on the metal’s surface that is significantly thicker and more durable than naturally occurring oxide layers. This oxide film acts more like a bio-inspired armor, diffusing light, absorbing pigments, and offering exceptional protection from physical and chemical degradation.

The Electrochemical Transformation: Nature Meets Technology

The process begins with the aluminum sheet submerged in an electrolytic bath—often sulfuric, oxalic, or other acids tailored for specific outcomes. When an electrical current is applied, aluminum acts as the anode, and oxygen ions are driven to form an aluminum oxide (Al₂O₃) layer atop it.

This layering is akin to a sculptor meticulously carving out a masterpiece — only here, the “sculpting” involves a tightly controlled oxidation reaction. How deeply this oxide layer penetrates and how uniform it remains depend heavily on voltage, temperature, electrolyte composition, and duration. From a microscope's vantage point, this film breathes new life into the substrate, enhancing its physical properties while providing a uniquely receptive surface for colorization.

Dyeing and Sealing: Personalizing the Surface

Now to the most visually expressive part of the process — coloring. Since the anodized layer is porous at the microscopic level, it readily absorbs dyes or pigments introduced through an immersed process. This step permits classrooms, designers, and engineers alike to imbue aluminum sheets with vibrant, long-lasting hues.

Sealing follows, locking in the color and further consolidating the oxide layer. It’s akin to sealing a painter’s canvas from the elements—once sealed, the aluminum sheet’s surface becomes remarkably resistant to scratches, UV radiation, and corrosion.

Ponder the process not just as a aesthetics enhancement but also as a trade-off between forms and function. Anodized aluminum sheets are prized in architectural facades, aerospace, interior design, and transportation for their resilience. The anodized surface maintains its skin-like integrity under extreme temperature swings and mechanical stresses, illustrating how a beautiful surface can also be a practical armor.

Limitations and Considerations

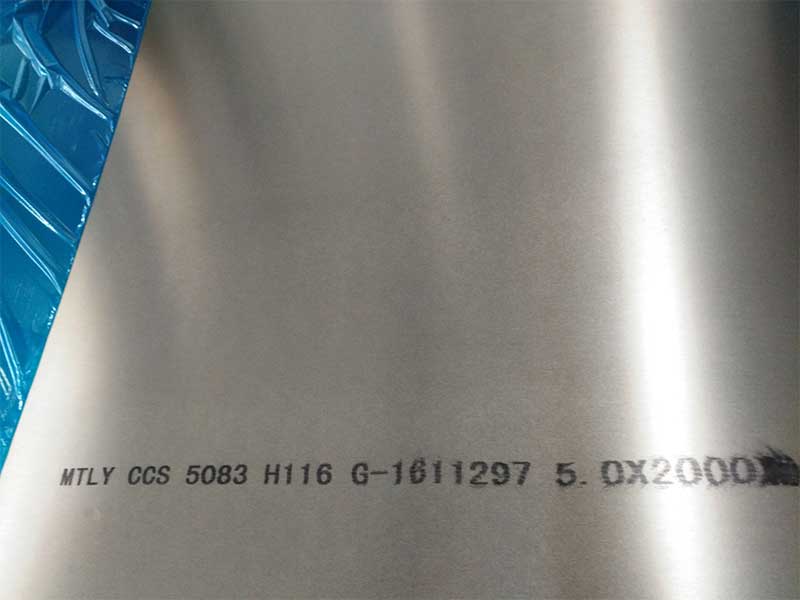

Of course, no process is infallible. Achieving perfect uniformity in the oxide film demands precision because variations lead to inconsistencies in color and durability. This need for meticulous control brings to light the importance of specialized equipment, rigorous quality control, and experience — crucial elements for those who wish their anodizing processes to produce superior outcomes.

In essence, anodizing aluminum sheets is a dance between electrochemistry and craftsmanship, where each parameter tweaks the final effect—be it a matte finish, gloss, or vibrant hue. From this distinctive point of view, anodizing stands as a testament to how harnessing science’s nuanced reactions can transform a simple metal sheet into an enduring, aesthetic, and high-performance component.

The next time you admire an aluminum facade, appliance, or aircraft embellishment, remember that behind its shimmering or matte surface lies a meticulously controlled electrochemical symphony — turning mere aluminum into a resilient and beautiful masterpiece of modern engineering.

https://www.aluminumplate.net/a/anodized-aluminum-sheet-anodizing-process.html